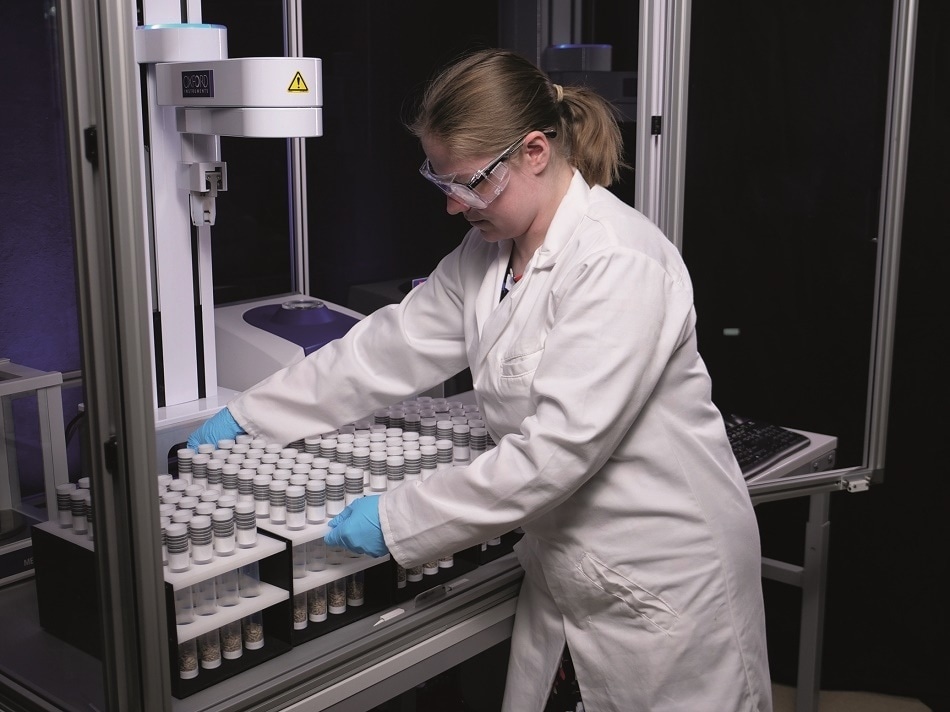

Oxford Instruments has launched MQ-Auto, a sample automation system for the MQC+ range of benchtop Nuclear Magnetic Resonance (NMR) analysers. MQ-Auto is a robotic system designed to extend the working time of the MQC+ and free up laboratory staff for more intensive tasks.

High performance robot

The MQ-Auto system is based around a high-performance robot arm and a range of sample racks and conditioning stations. An optional balance can be incorporated for applications that require samples to be weighed, and a barcode reader is also available for sample identification.

Easy Operation

The MQ-Auto is controlled by software running on either the internal computer of the MQC+ instrument, or on an external PC. The software allows samples to be run against different calibrations, and also allows operation to be paused mid-run for additional samples to be added. Optional barcodes can be attached to sample tubes to identify the sample and to store the tare weight of the tube for measurements that require weighing.

Safety

Operator safety is of course paramount with any electrical or mechanical installation, so comprehensive safety features have been built into the MQ-Auto. The robot arm itself is a so-called “collaborative robot”, designed to stop automatically if any obstruction is encountered in its path. In addition to this, the entire autosampler installation is housed in a transparent enclosure interlocked to shut down the robot arm if the door is opened. This two-level security protection ensures that the system can be operated safely with confidence.

Kevin Nott, Product Manager, Oxford Instruments said, “The MQ-Auto uses pioneering robotics to enhance the productivity of time domain NMR analysis and like the MQC+ it is interfaced with, it does not require an expert to use it.”

MQ-Auto is available to order immediately.