Nov 14 2018

Aluminum alloys are indispensable in space technology and aircraft manufacturing and possess unique material properties. Now, for the first time, scientists at TU Graz applied high-resolution electron tomography to successfully decode mechanisms that are important for comprehending the properties of these alloys. The results of the study have been reported in Nature Materials.

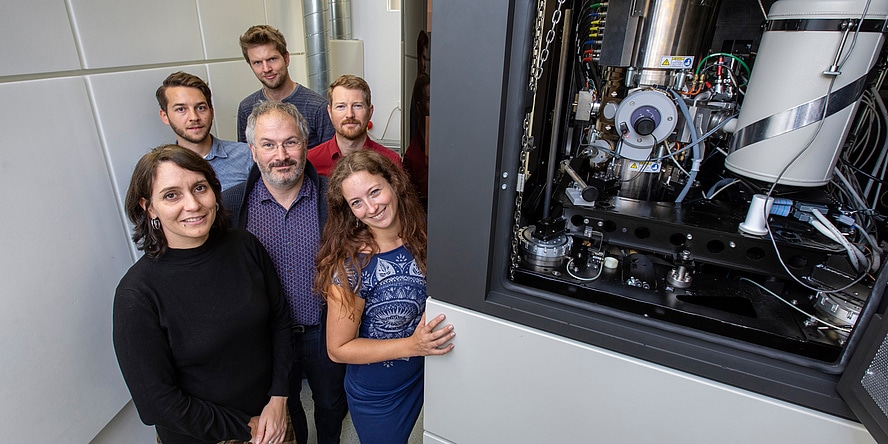

Gerald Kothleitner (centre) and his research team consisting of Maria Poletti and Angelina Orthacker (first row, from left to right) as well as Johannes Tändl, Georg Haberfehlner and Bernhard Sonderegger (back, from left to right) describe for the first time those atomic processes that lead to the formation of more powerful alloy materials with the help of the Austrian Scanning Transmission Electron Microscope (ASTEM) (Image credit: Lunghammer—TU Graz)

Gerald Kothleitner (centre) and his research team consisting of Maria Poletti and Angelina Orthacker (first row, from left to right) as well as Johannes Tändl, Georg Haberfehlner and Bernhard Sonderegger (back, from left to right) describe for the first time those atomic processes that lead to the formation of more powerful alloy materials with the help of the Austrian Scanning Transmission Electron Microscope (ASTEM) (Image credit: Lunghammer—TU Graz)

Nanostructures responsible for material quality

Zircon and scandium are alloy elements that are added to the aluminum matrix to enhance the weldability, corrosion resistance, and strength of aluminum alloys. Following additional treatment, small roundish particles—the so-called nano-precipitates that measure just a few nanometers in size—are formed. Their atomic structure, form, and the “struggle” of the zircon and scandium atoms for the “best place” in the crystal lattice are crucial for the material’s usability and properties.

These structures were examined by TU Graz researchers with the help of the Austrian scanning transmission electron microscope (ASTEM) at the Graz Centre for Electron Microscopy (ZFE). The ASTEM is capable of producing high-resolution element mappings of three-dimensional (3D) structures.

The thus arrived at tomographic analysis provided an image which, surprisingly, could not be interpreted according to the previous level of knowledge. We detected anomalies in the generated core-shell structures. On the one hand, we found higher quantities of aluminium in the nano-precipitates then we had presumed. On the other hand, we discovered a zircon-enriched core as well as border zones between the core and shell with an almost perfect composition and crystal structure.

Gerald Kothleitner, Institute of Electron Microscopy and Nanoanalysis, TU Graz

Quantum mechanics and Monte Carlo methods provide answers

In order to track down this phenomenon of self-organization, a research team from the Institute of Materials Science, Joining and Forming (IMAT) and the Institute of Electron Microscopy and Nanoanalysis (FELMI) turned to quantum mechanical simulations and calculations. The team discovered that the system is capable of separating itself and forming atomically narrow channels, wherein the foreign atoms can diffuse easily. These channels are blocked and the system is stabilized by atoms encountering one another.

The Austrian Cooperative Research (ACR) funded the thesis of a doctoral student Angelina Orthacker, who provided a graphic explanation of the atoms’ movement: “The diffusion process can be compared with the formation of an emergency corridor in an urban area with heavy traffic. The traffic manages to organise itself in a split second to enable the free flow of emergency vehicles. But it only takes a few individual vehicles to block the emergency corridor thus stopping it from working.”

This is exactly the same behavior in the interior of aluminum alloys. “Emergency corridors” encourage the material transport of zircon and scandium atoms and even small interruptions can halt this transport reaction. The researchers believe that the latest findings regarding these diffusion processes also have a role to play in other types of multi-component alloys, making it possible to further alter their properties.