Jan 7 2019

Cryogenic materials find an extensive selection of applications in everyone’s life, for example, the gas industry, applied superconductors, and deep-space exploration.

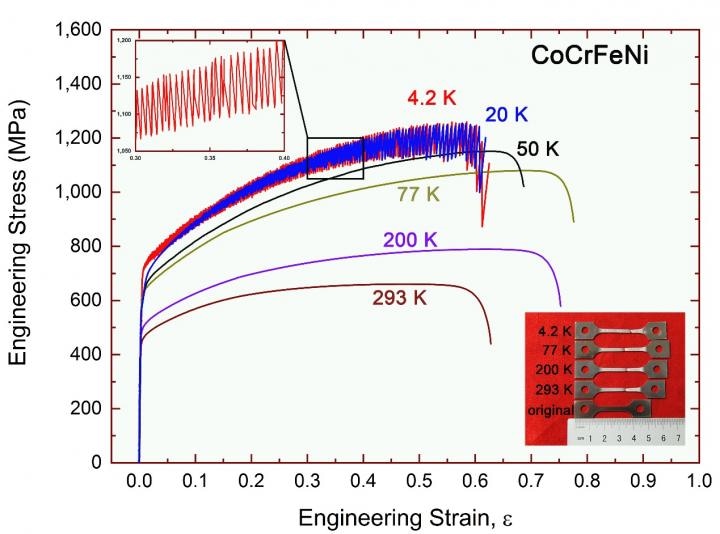

The tensile test of CoCrFeNi high-entropy alloy at different temperatures. (Image credit: Science China Press)

The tensile test of CoCrFeNi high-entropy alloy at different temperatures. (Image credit: Science China Press)

Thanks to the development of fusion reactor field and space technology, producing high-performance materials in adverse conditions, particularly at extremely low temperatures, has increasingly become an imminent mission. However, it is still a major challenge to create metals and alloys that have excellent ductility (ε_f>60%) and high-strength (σ_UTS>1GPa) at very low temperatures.

High-entropy alloys (HEAs), being a fire-new material, show an extremely-broad philosophy on how to integrate elements. The robust mixture approach offers immense opportunity to find something new and interesting. In such conditions, the service performance of high-entropy alloy under extreme condition certainly becomes something which everyone is curious about.

In this study, the researchers have evaluated the mechanical response of the CoCrFeNi high-entropy alloy (see the results in the above image), and found that this alloy shows an elongation to failure of 62% and a high ultimate tensile strength of 1.26 GPa at 4.2 K, which are the best among nearly all of the metallic materials. This study found that the superior mechanical performance at such low temperatures is due to the extensive deformation twinning and phase transformation from a face-centered cubic (FCC) structure to a hexagonal close-packed (HCP) structure. Furthermore, the stress-strain curves of this alloy exhibit the serration feature at liquid-helium temperatures and the authors inferred that the phase transformation and high-density twinning contribute to the serration feature, and that the FCC-HCP transition renders the serrated flow unstable.

Besides portraying an important breakthrough in the fundamental materials science, the results of high-mechanical performance at low temperatures, phase transition, and serration signify remarkable prospects and potential applications of HEA in the field of extreme cryogenic engineering.