Jan 31 2019

An innovative technology harnessing sunlight to fuel chemical reactions could result in a more sustainable chemical manufacturing sector, which happens to be the biggest energy consumers in the world.

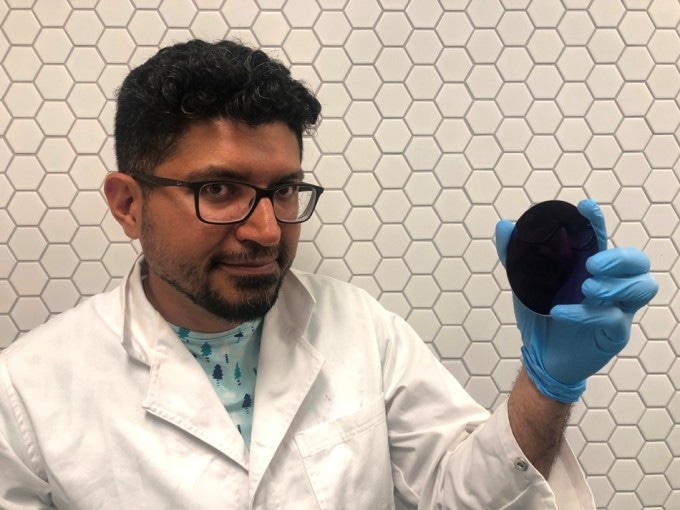

ARC Future Fellow, Associate Professor Daniel Gomez, holding a disc covered in the nano-enhanced palladium. (Image credit: RMIT University)

ARC Future Fellow, Associate Professor Daniel Gomez, holding a disc covered in the nano-enhanced palladium. (Image credit: RMIT University)

Researchers from RMIT University have created a new nano-enhanced material that is capable of capturing as high as 99% of light and converting it to drive chemical reactions.

In addition to reducing the environmental impact associated with the manufacture of chemicals, the latest breakthrough could be used for delivering technologies like solar-powered water desalination and better infrared cameras, in the future.

The study results, reported in ACS Applied Energy Materials, deal with the challenge of identifying alternative sources of energy for chemical manufacturing, which is responsible for around 7% of industrial greenhouse gas emissions and approximately 10% of the world’s energy consumption.

Chemical manufacturing in the United States utilizes more energy when compared to all other industries; in fact, in 2017 alone, the industry was responsible for 28% of industrial energy consumption.

Although photocatalysis—in which light is used to power chemical reactions—is expanding in the industry, cost and efficiency continue to be considerable barriers to broader take-up.

According to Daniel Gomez, the lead investigator and Associate Professor, the novel technology optimized the absorption of light to efficiently transform light energy into chemical energy.

Chemical manufacturing is a power hungry industry because traditional catalytic processes require intensive heating and pressure to drive reactions. But one of the big challenges in moving to a more sustainable future is that many of the materials that are best for sparking chemical reactions are not responsive enough to light. The photo catalyst we’ve developed can catch 99% of light across the spectrum, and 100% of specific colours. It’s scaleable and efficient technology that opens new opportunities for the use of solar power—moving from electricity generation to directly converting solar energy into valuable chemicals.

Daniel Gomez, Study Lead Investigator and Associate Professor, RMIT University.

Gomez is also an ARC Future Fellow in RMIT University’s School of Science.

Nano-tech for solar power

The study centered on palladium—an element that has an excellent ability to produce chemical reactions but often not sufficiently sensitive to light. By exploiting the optical characteristics of palladium nanoparticles, the team was able to render the material more responsive to light.

Although palladium is a costly and rare element, the method needs only a small amount—that is, 4 nm of nano-enhanced palladium is sufficient to absorb 99% of light and realize a chemical reaction. For comparison purposes, an average human hair has a thickness of 100,000 nm.

Apart from chemical manufacturing, the new breakthrough can be additionally developed for a host of other promising applications, such as improved night vision technology by creating images that are clearer and more sensitive to light.

Desalination is yet another promising application. The nano-enhanced material can possibly be added to salty water, which can then be exposed to sunlight; this would produce an adequate amount of energy to boil and evaporate the water, thus isolating it from the salt.

According to Gomez, who heads the Polaritonics Lab at RMIT University, the innovative technology can considerably maximize the yield in the emerging photo-catalysis industry, with major companies currently using light as the driving force to produce approximately 30 kg of product every day.

We all rely on products of the chemical manufacturing industry - from plastics and medicines, to fertilisers and the materials that produce the colours on digital screens. But much like the rest of our economy, it’s an industry currently fuelled by carbon. Our ultimate goal is to use this technology to harness sunlight efficiently and convert solar energy into chemicals, with the aim of transforming this vital industry into one that’s renewable and sustainable.

Daniel Gomez, Study Lead Investigator and Associate Professor, RMIT University.

The study, with collaborators from CSIRO, University of Melbourne, and the Melbourne Centre for Nanofabrication, has been reported in ACS Applied Energy Materials.

A paper showing analogous technology utilizing gold nanoparticles will be published in an upcoming edition of the journal ACS Photonics.