Micromeritics Instrument Corporation today announced the release of ‘The Definitive Guide to Powder Characterization’ a new whitepaper that showcases the analytical techniques available to optimally support the development and manufacture of commercially successful powder products.

Boosted by the acquisition of Freeman Technology Ltd, a global leader in powder testing technology, Micromeritics Inc. now offers an unrivaled toolkit for powder characterization. The new paper explains how different techniques work and the value of the resulting data in building a comprehensive understanding of powder performance. Its applicability extends across the powder processing industries –from food and pharmaceuticals to additive manufacturing, catalysts and many more. To download the guide, go to https://www.micromeritics.com/Product-Showcase/Powder-Characterization.aspx

“Particles are usefully described as a small portion of matter, individual entities with, for example, a defined size and shape, while powders are more helpfully considered as bulk assemblies,” said Randy Byrne, Micromeritics Global Head of Marketing. “They contain particles but also (most usually) air, and often moisture too. The properties of the particles that make up a powder product often define key aspects of performance – reactivity, sorption capacity, for example, or dissolution profile. They also, along with ‘system’ variables, such as the degree of aeration or consolidation, impact bulk powder properties such as the powder flowability. These, in turn, define both process and product performance.”

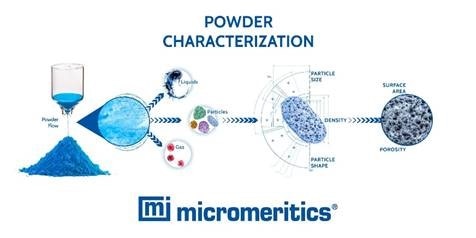

Byrne added, the analytical toolkit for those looking to efficiently manufacture powder products to rigorously controlled standards, therefore, extends from particle characterization to bulk powder testing. This paper covers techniques for analyzing particle structure, including surface area and porosity, for quantifying particle properties such as density, size and shape, and for the measurement of powder properties – flowability, compressibility, permeability and density. It also includes examples demonstrating how the techniques are applied together in specific applications - in the development of high-performance metal powders for additive manufacturing and robust formulations for oral solid dosage.

For most powder processors a handful of analytical techniques holds the key to exemplary product performance and efficient manufacture. This guide makes it easier to identify these techniques for any specific application.