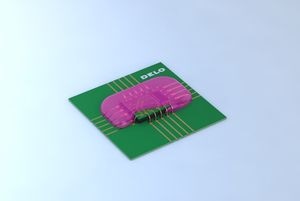

DELO has developed an encapsulant with very high resistance to media and temperature. Thanks to an optimized curing time, DELO MONOPOX GE6515 also accelerates production processes. The product is particularly well suited for encapsulating electronic components in automotive applications.

DELO MONOPOX GE6515 is a one-component, purely heat-curing epoxy resin. The encapsulant achieves very high strength even at high temperatures. It exhibits strength values of 20 MPa on aluminum at a temperature of 150 °C and 14 MPa in the upper service temperature range of 200 °C.

Developed especially for encapsulating electronic components, the product also achieves excellent adhesion on materials such as FR4, FA, and copper. In addition, the epoxy resin is highly resistant to chemicals such as oils, acids, or fuels.

The encapsulant has a coefficient of thermal expansion (CTE) matching that of materials commonly used in the automotive industry. The CTE is 23 ppm/K up to the glass transition temperature (Tg) of 155 °C and 48 ppm/K above Tg. A small CTE is especially important for applications where temperature-induced warpage has to be avoided.

DELO MONOPOX GE6515 cures in an air convection oven at temperatures ranging from 90 °C to 150 °C. At 130 °C, the epoxy resin is fully cured after just 15 minutes, making production processes faster.

DELO MONOPOX GE6515 has a processing time of one week. Within this period, the encapsulant can be optimally applied to the component. With only 48 hours, the processing time of products typically used for such applications is significantly lower.