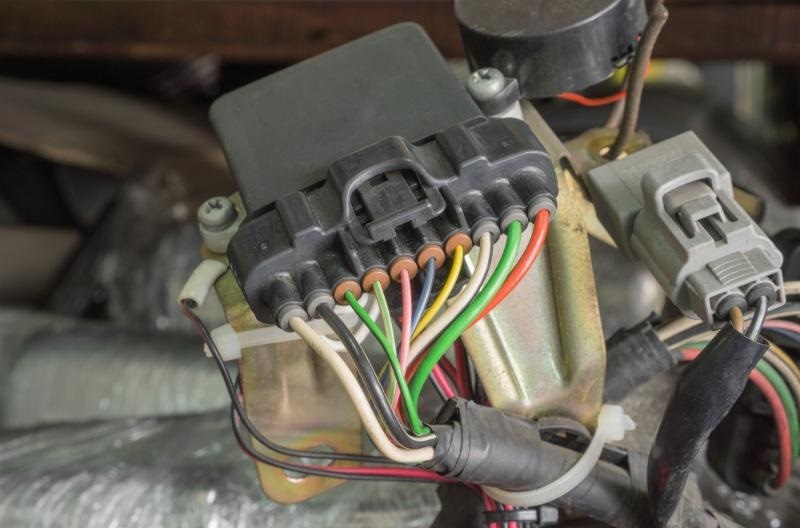

The automotive industry continues to find new and improved ways to manufacturer automobiles, especially the engine and electrical components that monitor and improve vehicle operations. The wiring used for these new electronics must be able to handle higher temperatures.

These new challenges created a need for the Chroma Color technical team to develop solutions that perform well in high heat environments. Our technical team was able to successfully engineer new products for customers with T1, T2, & T3 wire application needs. Chroma Color Corporation T1, T2 & T3 products are designed for ISO 6722 85°C, 105°C and 125C rated in thermoplastic and cross-link compounds.

Concentrates recommended for use with 85C rated compounds have been formulated and verified to provide minimum thermal stability of 70 minutes at 200C; those recommended for use with 105C and 125C rated compounds have been formulated and verified to provide minimum thermal stability of 150 minutes at 200C. Thermal stability is assessed using the dehydrochlorination (DHC) test.

Custom matched color concentrates are available upon request. Recommended letdown ratios are between 1 and 2 %. As always, we encouraged customers to perform tests in the specific compound(s) being used to determine the amount of color concentrate needed to attain the desired color.

All products are compliant with the following regulatory statutes:

- CA Prop 65

- EU 2002/61/EC (Use of Azo Colourants)

- EU 2000/53/EC (Vehicle End of Life)

- EU 2002/95/EC, 2011/65/EU and 2015/863/EU (RoHS)

- EU 2002/96/EC (WEEE)

- REACH SVHC

- Automotive GADSL