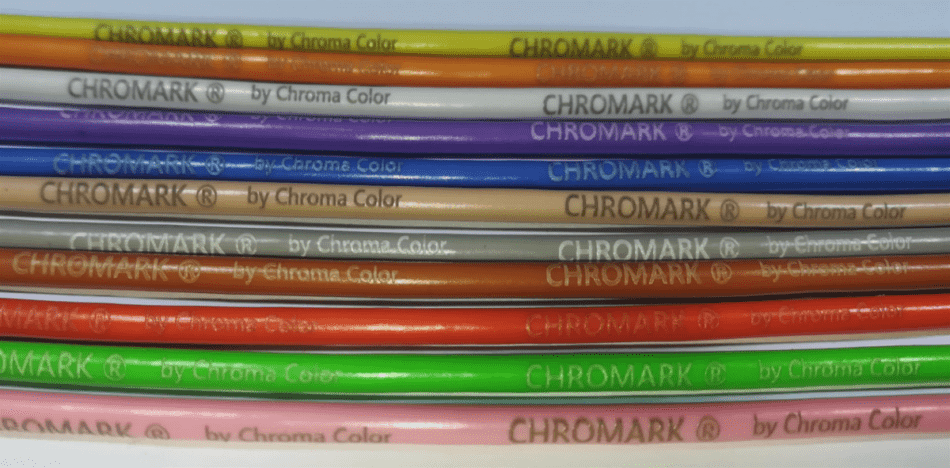

Chroma Color Corporation announces the launch of CHROMARK® laser marking additives and concentrates to mark plastics extremely fast, contactless, cleanly, precisely, at a low cost and permanent compared to pad printing or adhesive labels.

Depending on the type of additive used, the desired mark, and the color concentrate used, different marking Mark types may be considered. Foaming, engraving, ablation, carbonization, and bleaching are the primary mark types for plastics. For marks that don’t involve material removal, LASER marking additives can produce light marks on dark colored parts, and dark marks on light colored parts primarily by the foaming and carbonization mechanisms. Though many concentrates are inherently mark-able, additives improve the marking depth, contrast, and durability. Careful selection of pigments, stabilizers, and resins can also improve the mark performance.

The team at Chroma Color Corporation can help you select the right CHROMARK® colorant and additive package to ensure you obtain the ideal laser mark for your product at an economical cost-to-color. With the in-house NIR Laser, the team can optimize the marking behavior and laser settings for a variety of resins including ABS, PE, PP, LDPE, HDPE, Co- Polyester, PBT, Polysulfone, GPPS, HDPE, Nylon, Acrylic, PVC, Polyacetal, and Polycarbonate. In addition, Chroma’s patented G3® technology can also provide highly loaded concentrates with laser marking additives.