RPI UK, the world’s leading specialist in precision positioning devices for high accuracy rotary and angular inspection systems, will be launching the QuadProfile at Control 2019 in Stuttgart. It will also be exclusively previewing its RotoScan system. What’s more, all this will be debuting on RPI’s larger and completely redesigned new exhibition space on stand 7108.

Jim Palmer, RPI’s sales manager, said: “We’re thrilled to launch our all new QuadProfile at Control this year. This development delivers a brand-new capability to the CMM market, as the smallest and most accurate rotary table for turbine blade inspection. We are also demonstrating our prototype RotoScan at front of stand which is a robotic system that automates circular geometry in the same way its previously been achieved for non-contact metrology.”

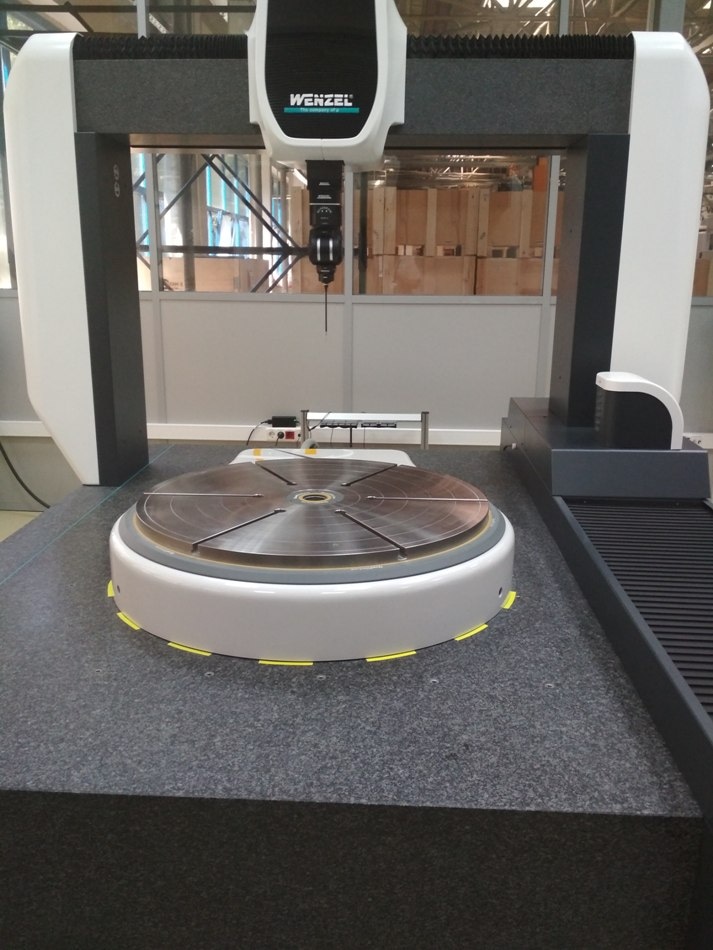

RPI have more than 750 successful CMM (Coordinate Measuring Machine) rotary table installations worldwide. The Quadrant range of rotary tables provide an additional axis for any high precision CMM inspecting component parts such as gas turbine discs and fan blades.

Not only does this simplify the measurement procedure, it helps to deliver fast and accurate indexing as well as increase the CMM’s application range and effective measuring volume. Overall, this improves the flexibility, productivity and efficiency of the CMM inspection.

The new addition to the Quadrant range, QuadProfile further enhances RPI’s product portfolio enabling the ultimate in low profile and compact rotary table design for the CMM market.

Meanwhile, RotoScan has been designed to automate the inspection of heavy-duty circular components with large diameter such as bearings, aerospace castings and rotors. It uses a robot to automate the inspection capability of components using traditional contact metrology techniques to improve the repeatability and reproducibility of the measurements. RotoScan has been developed with AccuScan software and also compliments other assembly platforms such as iMAP and GeoSpin.

In addition to these new developments, RPI will also be demonstrating its LabStandard range which offer sub arc second angular accuracy and precision geometry for inspection and calibration labs, with the versatility of both single and dual axis.

LabStandard and LabStandardDUO are typically used for calibration of inclination sensors and navigation systems such as gyroscopes enabling both horizontal and vertical application. It combines a preloaded axial and radial rolling bearing to provide high rigidity in both planes ideal for heavy off centred loads. LabStandard is essential for anyone working in metrology or precision testing.