Apr 19 2019

A structure is typically formed when small and uniform building blocks interact with each other, causing synthetic materials to self-assemble together.

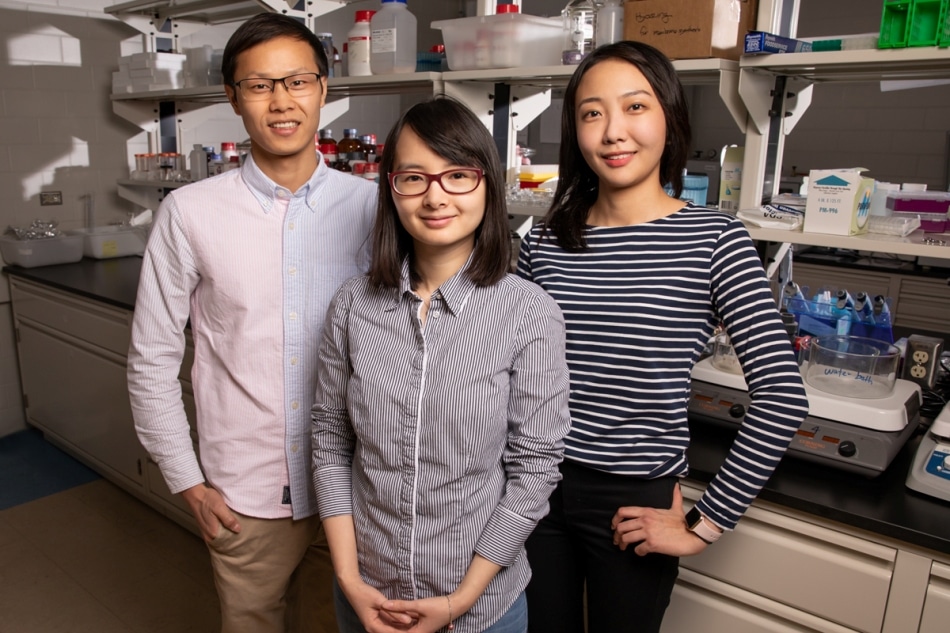

Materials science and engineering professor Qian Chen, center, and graduate students Binbin Luo, left, and Ahyoung Kim find inspiration in biology to help investigate how order emerges from self-assembling building blocks of varying size and shape. (Image credit: L. Brian Stauffer)

Materials science and engineering professor Qian Chen, center, and graduate students Binbin Luo, left, and Ahyoung Kim find inspiration in biology to help investigate how order emerges from self-assembling building blocks of varying size and shape. (Image credit: L. Brian Stauffer)

Yet, nature allows materials like proteins of varied shape and size to assemble, enabling intricate architectures that are capable of handling numerous tasks.

Now, engineers at the University of Illinois have closely studied how synthetic particles that are non-uniform are able to assemble together, and they unexpectedly discovered that this phenomenon takes place in various phases, paving the way for novel reconfigurable materials for applications in technologies like catalysis and solar cells. The results of the study have been published in the journal, Nature Communications.

Traditional self-assembly can be thought of like a grocery store stacking apples for a display in the produce section. They would need to work with similarly sized and shaped apples—or particles in the case of self-assembly—to make the structure sturdy.

Qian Chen, Study Lead Author and Professor, Department of Materials Science and Engineering, University of Illinois at Urbana-Champaign

In the latest research, Chen’s team looked at the behavior of microscale silver plates of nanoscale thickness and varied size in liquids. Since the particles utilized in self-assembling materials are very tiny, they act like molecules and atoms, enabling scientists to apply traditional physics and chemistry theories in order to infer their behavior, stated the research team.

In accordance with the laws of nature in plain, deionized water, the non-uniform particles attract and repel each other. Yet, when salt is added to the water, a multistep assembly process is activated by fluctuating electrostatic forces. The non-uniform particles start to organize to create columns of stacked silver plates and additionally assemble into progressively intricate and well-ordered 3D hexagonal lattices, the researchers discovered.

We can actually witness the particles assemble in this hierarchy using a light microscope. This way, we can track particle motions one by one and study the assembly dynamics in real time.

Binbin Luo, Study Co-Author and Graduate Student, Department of Materials Science and Engineering, University of Illinois at Urbana-Champaign

The findings of this study may allow for the development of reconfigurable self-assembly materials. These materials can change from one type of solid crystal to another type with different properties for a variety of applications.

Ahyoung Kim, Study Co-Author and Graduate Student, Department of Materials Science and Engineering, University of Illinois at Urbana-Champaign

Another benefit of this finding is that it can be generalized to other types of systems. If you have another type of nanoparticle, be it magnetic or semiconducting, this hierarchal assembly principal still applies, allowing for even more types of reconfigurable materials.

Qian Chen, Study Lead Author and Professor, Department of Materials Science and Engineering, University of Illinois at Urbana-Champaign

The study also included former postdoctoral researcher Juyeong Kim, graduate students Zihao Ou and John W. Smith, and undergraduate student Zixuan Wu.

The study was supported by the National Science Foundation.