Tasked with creating a demolding gripper that would yield extremely fast cycle times to achieve a high output, FIPA developed a high-performance, cost-effective solution for German manufacturer Franke Kunststofftechnik GmbH & Co. KG.

Founded in 1989, Franke Kunststofftechnik GmbH & Co. KG (https://www.franke-online.de/) has asserted itself in the rapidly growing plastics industry with a broad range of products and services relating to injection molding. Franke offers customers from the automotive, heating, solar, window, and electronics industries an efficient process chain that ranges from design to production. The German family business’ portfolio includes the development, design, simulation, prototyping, and production of injection molding tools, totaling up to 19 tons in weight. Franke has 15 state-of-the-art injection molding machines with claming forces ranging from 50 to 1,500 tons that produce thermoplastic parts.

The Task: Developing a Demolding Vacuum Gripper for Higher Throughput

In search of a device that would quickly and simulanteously remove and place eight battery covers from an injection molding machine, Franke Kunststofftechnik GmbH & Co. KG, a German manufacturer of injection molding tools for the plastics industry, approached FIPA with the application challenge. Using vacuum cups to remove injection molded parts is a difficult step in the process, because the vacuum cups must be resistant to high temperatures and, in many applications, they should not leave any marks on the material being demolded.

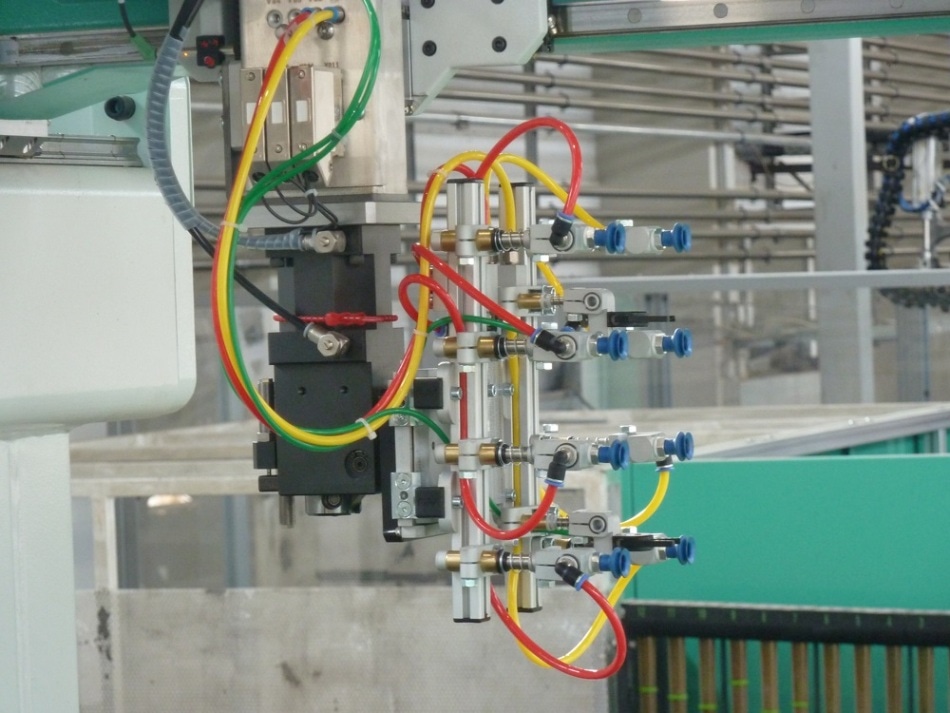

The Solution: A Customized Gripper with Thermalon® Vacuum Cups

“After thoroughly discussing and reviewing Franke’s technology application needs, we realized our Thermalon® vacuum cups would be an ideal solution for this particular project,” said Timo Bendrat, FIPA Sales Manager for Western Germany. “Our Thermalon® vacuum cups are comprised of a material optimized for the specific needs of the plastics industry, because it is heat-resistant up to 160°C and low-marking.”

Combined with the vacuum cups, FIPA created a customized gripper that weighs less than 2.5kg, has a two seconds removal time, and provides a cycle time of just 19.2 seconds from injection molding to placing, thus enabling a production throughput of up to one million parts per year. FIPA’s latest innovate gripper solution is also a first for Franke, who previously only used tools for demolding parts from 4 cavity molds.

“It was an absolute pleasure to work with FIPA, who responded quickly to our inquiry, worked diligently to ensure that this project ran smoothly, and was managed in a timely fashion,” said Niklas Franke, who is responsible for application technology at Franke Kunststofftechnik GmbH & Co. KG. “The result was a highly effective, and cost-sensitive solution that successfully met our application technology requirements.”

For more information about the plastics application please visit YouTube to watch a short video about the customized gripper in action.