May 29 2019

A group of scientists from the University of Minnesota and University of Massachusetts Amherst has invented new technology that can accelerate chemical reactions 10,000 times faster when compared to the existing reaction rate limit.

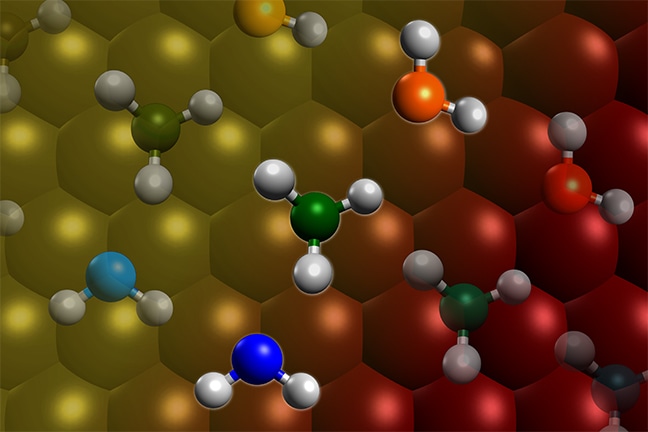

A new discovery by University of Minnesota and University of Massachusetts Amherst researchers could increase the speed and lower the cost of thousands of chemical processes used in developing fertilizers, foods, fuels, plastics, and more. (Image credit: University of Minnesota)

A new discovery by University of Minnesota and University of Massachusetts Amherst researchers could increase the speed and lower the cost of thousands of chemical processes used in developing fertilizers, foods, fuels, plastics, and more. (Image credit: University of Minnesota)

The study outcomes could improve the speed and decrease the cost of thousands of chemical processes used in producing foods, fertilizers, plastics, fuels, and so on.

The study is reported online in ACS Catalysis, a leading journal of the American Chemical Society.

In chemical reactions, researchers use so-called catalysts to accelerate reactions. A reaction taking place on a catalyst surface, for example, a metal, will accelerate; however it can only go as fast as allowed by the so-called Sabatier’s principle—usually referred to as the “Goldilocks principle” of catalysis.

The best possible catalyst works to perfectly balance two sides of a chemical reaction. Reacting molecules must adhere to a metal surface to react neither too strong nor too weakly, but “just right.” As this principle was set up quantitatively in 1960, the Sabatier maximum has remained in the catalytic speed limit.

Scientists of the Catalysis Center for Energy Innovation, funded by the U.S. Department of Energy, found that they could exceed the speed limit by applying waves to the catalyst to develop an oscillating catalyst. The wave has a top and bottom, and when applied, it allows both parts of a chemical reaction to take place independently at different speeds. When the wave applied to the catalyst surface matched the natural frequency of a chemical reaction, the rate increased significantly through a mechanism known as “resonance.”

We realized early on that catalysts need to change with time, and it turns out that kilohertz to megahertz frequencies dramatically accelerate catalyst rates.

Paul Dauenhauer, Study Author and Professor, Chemical Engineering and Materials Science, University of Minnesota

Only a few metal catalysts can access the catalytic speed limit or Sabatier maximum. Other metals that have a stronger or weaker bond demonstrate slower reaction rate. Due to this, graphs of catalyst reaction rate versus metal type have been referred to as “volcano-shaped plots” with the best static catalyst existing right in the middle at the volcano peak.

The best catalysts need to rapidly flip between strong and weak binding conditions on both sides of the volcano diagram. If we flip binding strength quickly enough, catalysts that jump between strong and weak binding actually perform above the catalytic speed limit.

Alex Ardagh, Post-Doctoral Scholar, Catalysis Center for Energy Innovation

The potential to speed up chemical reactions directly influences thousands of chemical and materials technologies used to produce foods, fertilizers, plastics, fuels, and so on. In the last hundred years, these products have been optimized using static catalysts, for example, supported metals. Improved reaction rates could considerably decrease the number of equipment needed to manufacture these materials and reduce the overall costs of several daily-use materials.

In addition, remarkable improvement in catalyst performance has the ability to level down systems for distributed and rural chemical processes. Due to cost savings in large-scale traditional catalyst systems, most materials are only produced in huge centralized locations like refineries. Faster dynamic systems can be minor processes, which can be set up in rural locations like ethanol plants, farms, or military installations.

This has the potential to completely change the way we manufacture almost all of our most basic chemicals, materials, and fuels. The transition from conventional to dynamic catalysts will be as big as the change from direct to alternating current electricity.

Professor Dionisios Vlachos, Director, Catalysis Center for Energy Innovation