Bindatex, the UK’s leading provider of composite precision slitting services, is celebrating 10 years of partnership and delivering 50 tonnes of multiaxial fabrics to a global composites reinforcement manufacturer. The specialist slitting service enables the manufacturer to supply its customers with material in a wide variety of widths.

Multiaxial, stitched non-crimp fabrics (NCF) are constructed from numerous layers of carbon or glass fibres and these are held in place with a polyester thread. The fibres can be in a variety of orientations, for example +45/90/-45 degrees. One of the advantages of using multiaxial composites over woven materials is that they can increase efficiency in the lamination process as multiple layers of thicker fabrics can be laid up more quickly.

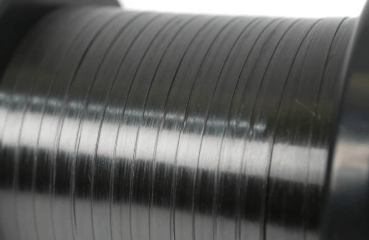

The use of multiaxial reinforcements in composite manufacturing is growing and this has been driven by the ability to slit these fabrics into a variety of tape widths. However, the construction of this type of material presents many challenges during the slitting process. It is vital to ensure a clean cut and accurate slit edge without compromising the fibre orientation and the handling characteristics of the materials. The tapes can be slit as narrow as 35mm and multiple widths can be achieved from each roll. The advantage of mixing the slitting pattern within a single roll helps to ensure maximum utilization from the material thus reducing waste.

Bindatex’s slit multiaxial tapes have been used throughout the aerospace, marine and automotive industries, ranging from the manufacture of high-performance components to carbon fibre wheels.

Chris Lever, Bindatex Managing Director, said: “We are well ahead of the game slitting difficult to cut materials and in delivering spliced tapes to very high precision. It’s fantastic to be working with this global manufacturer in the production of carbon fibre for a variety of applications.”

As well as being experts in the slitting of multiaxial carbon fibre and glass products, the company has been at the forefront of precision narrow width slitting of uni-directional (UD) composite tapes for innovative aerospace applications. It has also successfully developed the capability to produce ‘Lay-ready’ thermoplastic splices in UD tapes that are manufactured with PEEK, PAEK and PEKK polymers.

This development in proprietary technology will enable Bindatex to deliver defined spool lengths which can help to increase its customers’ productivity on automated fibre placement (AFP) and automated tape laying (ATL) equipment.

Through collaboration with customers, Bindatex has been able to provide innovative solutions to known problems with thermoplastic UD tapes which has helped to aid further adoption of these next generation composite materials.

Bindatex has vast experience in cutting composite carbon and glass fibre prepreg materials in diverse formats including unidirectional (UD) tapes and traverse wound spools; thermoplastic and thermoset carbon fibre prepreg; woven fabrics; multiaxial fabrics and non-woven materials.

The UK-based company is an approved supplier to major thermoplastic and thermoset manufacturers across the globe. Its customers include world class material manufacturers and end users across composites, aerospace, automotive, marine, advanced manufacturing, healthcare, energy and renewables.

Since moving into larger premises in 2018, Bindatex has doubled its capacity. The company’s modern manufacturing facility comprises state-of-the-art slitting machines capable of handling everything from narrow width precision slitting for automated fibre placement to automated tape laying; flake/chopped fibre production, micrometer slitting/kiss cutting; traverse wound spooling as well as die and sheet/panel cutting.