Jun 19 2019

Scientists from the Pacific Northwest National Laboratory (PNNL) have recently demonstrated a sophisticated manufacturing process to create nanostructured tubes and rods directly from high-performance aluminum alloy powder, all in just one step.

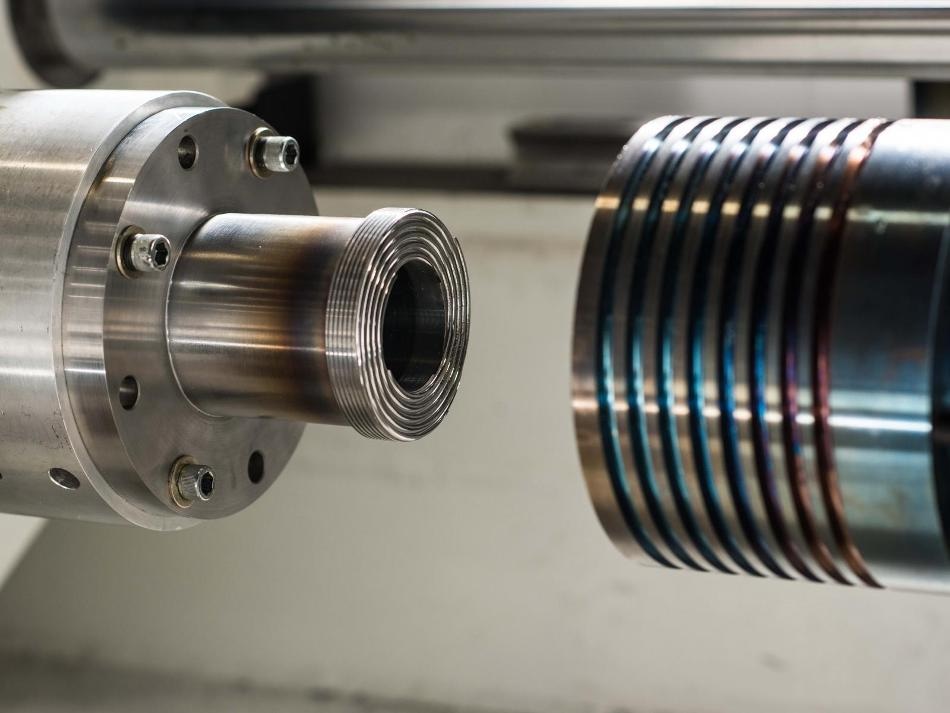

(Image credit: Pacific Northwest National Laboratory)

(Image credit: Pacific Northwest National Laboratory)

With the help of an innovative solid phase processing technique, the researchers successfully eliminated a number of steps that are needed during traditional extrusion processing of aluminum alloy powders and, at the same time, achieved a considerable increase in product ductility, that is, the extent to which a material can expand before breaking down.

This is good news for industries like the automotive sector, where exorbitant manufacturing costs have traditionally restricted the use of high-strength aluminum alloys created from powders. The researchers’ study has been detailed in the paper titled “High Ductility Aluminum Alloy Made from Powder by Friction Extrusion,” published in the June 2019 issue of Materialia.

Stepping Away from Conventional Extrusion

Typically made from powder, high-performance aluminum alloys have traditionally been employed in lightweight components for exclusive aerospace applications, where cost is not a major constraint. Conversely, for the automotive sector, such alloys have been extremely costly.

Energy and process-intensive is a usual extrusion process for aluminum alloy powders, needing numerous steps to create the material at large scale. The loose powder has to be first loaded into a can and then gases need to be removed through a vacuum, which is known as “degassing.” Following this, the can is subsequently sealed, hot-pressed, pre-heated, and finally placed into the extrusion press. The can is removed, or “decanned” after extrusion to expose the extruded part fabricated from the consolidated powder.

In this analysis, the researchers effectively eliminated most of these steps and directly extruded nanostructured aluminum rods from powder in just one step, with the help of Shear Assisted Processing and Extrusion technology, or ShAPE™, developed by PNNL.

An Al-12.4TM aluminum alloy powder was used in the ShAPE™ process. The powder was supplied by SCM Metal Products, Inc., a division of Kymera International. This powder is transferred to an open container, and a rotating extrusion die is subsequently forced into the powder, which produces heat at the interface between the die and the powder. The resultant material softens and extrudes easily, removing the necessity for canning, degassing, hot pressing, pre-heating, and decanning.

This is the first published instance of an aluminum alloy powder being consolidated into nanostructured extrusions using a single-step process like ShAPE™.

Scott Whalen, Materials Scientist, Pacific Northwest National Laboratory

Whalen headed the study.

The elimination of both the processing steps and the need for pre-heating could dramatically reduce production time as well as lower the cost and overall embedded energy within the product, which could be beneficial for automotive manufacturers who want to make passenger vehicles more affordable, lighter, and fuel-efficient for the consumer.

Scott Whalen, Materials Scientist, Pacific Northwest National Laboratory

In addition to offering the Al-12.4TM powder, SCM Metals Products, Inc. also carried out mechanical testing to confirm the performance of the resulting material. SCM Metal Products, Inc. and PNNL are currently teaming up on a project for DOE’s Office of Technology Transitions to further improve the process for extrusions of larger diameter.

Ductility—It’s a Stretch

However, reduced heating and elimination of processing steps were not the only fruitful findings made by the researchers.

High-performance aluminum alloys have traditionally exhibited superior strength, but they have been mostly limited by poor ductility. Yet, the researchers found significant enhancements in the ductility of the extrusion created by the ShAPE™ technology, determining ductility that is two to three times higher than that of traditional extrusion products, and with corresponding strength.

In order to figure out the reason for the considerable increase in ductility, transmission electron microscopy was utilized to assess the microstructures of the extruded materials and powder. The results denoted that the ShAPE™ technique refined the second phases in the powder—microscopic reinforcing particles of non-aluminum materials. The ShAPE™ method minimizes the particles to nanoscale sizes and uniformly distributes them across the aluminum matrix, boosting ductility.

The ShAPE™ technique is part of PNNL’s increasing suite of capabilities in solid phase processing, or SPP, a disruptive method for metals manufacturing that can be cheaper, better, and greener when compared to melt-based techniques that are often related to metals manufacturing.

The study was supported by the Materials Synthesis and Simulation Across Scales Initiative, a Laboratory Directed Research and Development project at PNNL. Apart from Kymera International, scientists from the University of California, Riverside also teamed up on this project.

A New Manufacturing Process for Aluminum Alloys

(Video credit: Pacific Northwest National Laboratory)