NatureWorks has introduced Ingeo 3D450, a new break-away formulation for use in dual extrusion 3D printers. The clean, fast mechanical break-away of Ingeo 3D450 support structures results in parts with high finish quality, reducing post-processing time and improving overall productivity.

Achieve Excellent Precision and Printability

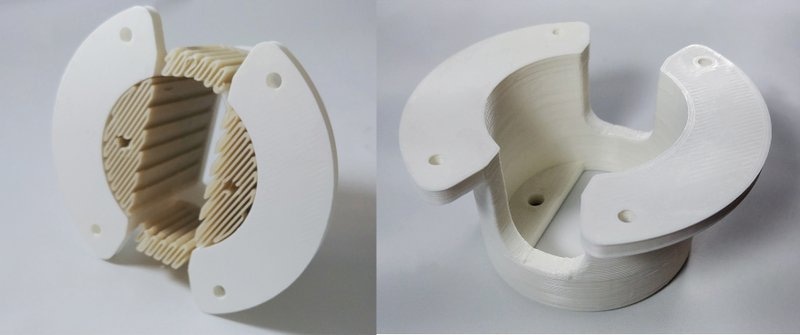

Applications for Ingeo 3D450 support material include complex industrial parts such as jigs and fixtures, patterns for investment metal casting, and architectural and retail models. Ingeo 3D450 is designed to work with the Ingeo 3D series of grades, including 3D850 and 3D870, that was developed for the professional printing market. At printing speeds up to 100 mm/s, Ingeo 3D450 prints and cools without warping even across large sections of support structures.

Ingeo 3D450 – New Formulation

- The Ingeo 3D450 break-away formulation can reduce or eliminate speed and buildability issues sometimes encountered with soluble support materials such as polyvinyl alcohol (PVA) or high-impact polystyrene (HIPS).

- Compared to these soluble supports, Ingeo 3D450 has a longer and more stable shelf life, dramatically reduced moisture sensitivity during printing, and reduces the need for post-processing with its clean break-away from a build.

- The new grade is compatible with large format printers, and since Ingeo 3D450 break-away supports do not rely on solvent baths for removal, 3D450 avoids the size constraints encountered with needing to submerse a build.

Several Partners Beta-Tested New Grade with Noted Positive Results

MatterHackers

“MatterHackers PRO Series Breakaway Support, using Ingeo 3D450, works well offering clean printed surfaces and clean breakaway material. It is more convenient than other, dissolvable, support offerings. There was no residue on the hot-end, and we found no filament or printing issues.”

Voodoo Mfg.

“There was a significant reduction in part cleaning times, about 10 times faster than using PLA supports. 3D450 prints faster than soluble support materials. Additionally, we have been able to lower the support roof to model spacing, which results in better bottom-part quality.”

Slant 3D

“Our team liked the increased brittleness. It was easier to break through grid supports. It flowed smoothly and consistently.”

Titan Robotics will demonstrate Ingeo 3D450 on its new Atlas hybrid filament and direct pellet extrusion print machine during the Additive Manufacturing Users Group Conference and Tradeshow (AMUG) in Chicago, March 31-April 4. The demonstration will feature Ingeo 3D450 filament made by 3D Fuel and will be held on Monday, April 1 from 10 a.m. to 2 p.m at the Titan Robotics booth (#78).

Filament made with Ingeo 3D450 is now available from 3D-Fuel and MatterHackers. Resin in 25-kg and 750-kg quantities is now available from NatureWorks and its sales channel partners in the United States, Asia, and Europe.