The DrySyn OCTO Mini reaction station from Asynt is enabling researchers to optimise and expand the applications of HydRegen - an innovative, heterogeneous biocatalytic hydrogenation technology currently under development within the group of Prof. Kylie Vincent at the University of Oxford (UK).

HydRegen technology provides a flexible platform of enzyme-modified carbon particles which facilitate cofactor-dependent biocatalysis for chemical synthesis. This pioneering technology addresses 2 key challenges with implementing NADH-dependent biocatalysis. The use of H2 as a reducing equivalent allows up to 100 % atom efficient biotransformations. The rapid, one-step enzyme immobilisation method is applicable to most biocatalysts and allows simple removal and re-use of the enzymes. In application, handling enzyme cascades as heterogeneous catalysts combines the advantages of biocatalysis and catalytic hydrogenation for highly selective hydrogenation or deuteration reactions.

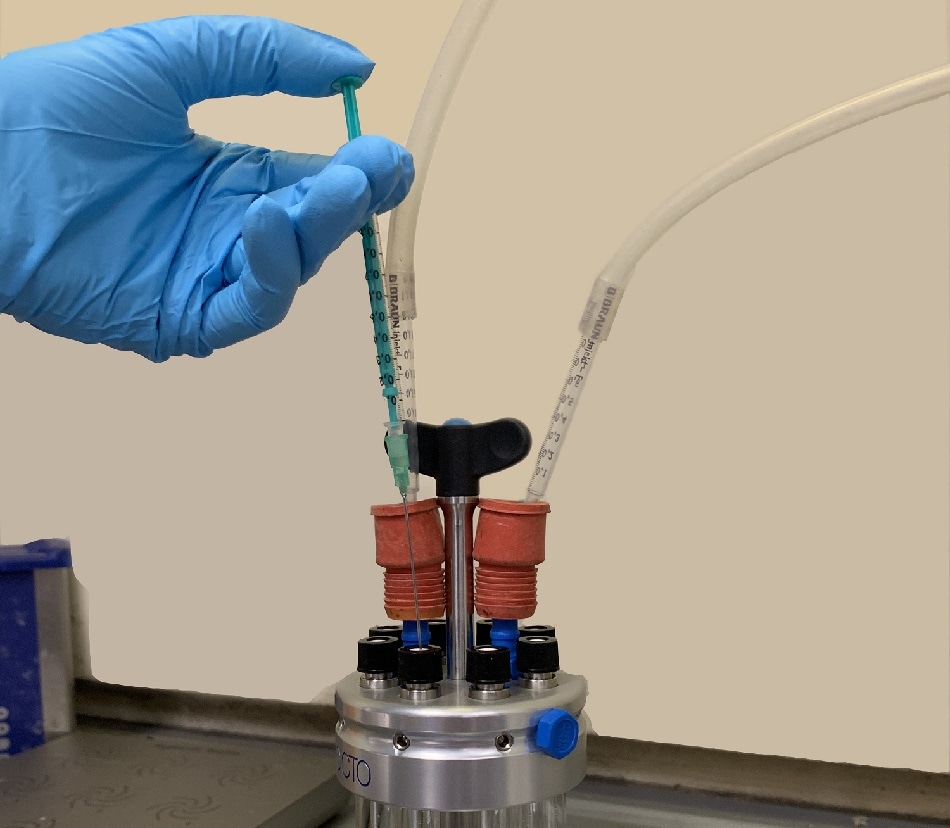

My job is to transition the HydRegen reaction set up from the glovebox to the benchtop, and ultimately to scale up the batch reactions. The recent addition of the mini DrySyn OCTO kit has been advantageous as it allows us the flexibility to optimise our catalyst on a smaller scale. The quality construction of the DrySyn OCTO kit provides a good airtight seal which is critical for reaction chemistries like HydRegen that require air-free conditions. The ability to screen eight reaction variations in the mini OCTO parallel reactor under controlled H2, temperature, and stirring has greatly expedited the process of optimising our system in a reproducible fashion. And because I work in a shared lab space, the OCTO has also been particularly convenient since it has a very small footprint.

Dr Sarah Cleary, Postdoctoral Research Associate, Vincent Group

The DrySyn OCTO Mini is an 8-position reaction station that provides powerful magnetic stirring and heating, inert atmosphere and reflux, all within a tiny footprint. Accommodating individual reaction volumes of up to 6ml, the DrySyn OCTO mini has been designed to use low-cost reaction tubes to save as much as possible on consumables for your lab. To further increase your throughput, up to 3 DrySyn OCTO mini reaction stations can be used together on a single standard magnetic hotplate stirrer therefore enabling up to 24 parallel reactions.

For further information on the DrySyn OCTO mini reaction station please visit https://www.asynt.com/product/drysyn-octo-mini/