Jul 29 2019

A research team has shown the potential application of machine learning (ML)—a form of AI that allows computers to “learn” from the data provided—for finding novel materials.

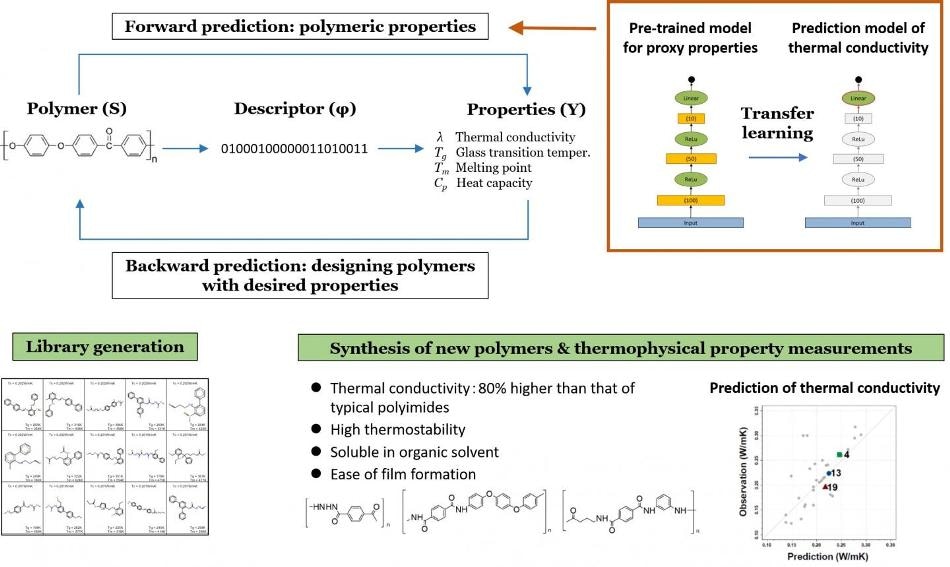

The ML workflow consists of two different steps of prediction; the forward and backward predictions. The objective of the forward prediction is to create a set of prediction models that describe various polymeric properties (for example, thermal conductivity, glass transition temperature) as a function of chemical structures in the constitutional repeat units. Here, an ML framework called transfer learning was used to overcome the issue of limited data on thermal conductivity: prediction models of some proxy properties were pre-trained on given large data sets, and then the pre-trained models were fine-tuned using the limited data on the target property. Inverting the trained forward models, they derived a backward model conditioned by a desired property requirement. By solving this inverse problem, materials that exhibit the desired properties were computationally created. (Image credit: NIMS)

The ML workflow consists of two different steps of prediction; the forward and backward predictions. The objective of the forward prediction is to create a set of prediction models that describe various polymeric properties (for example, thermal conductivity, glass transition temperature) as a function of chemical structures in the constitutional repeat units. Here, an ML framework called transfer learning was used to overcome the issue of limited data on thermal conductivity: prediction models of some proxy properties were pre-trained on given large data sets, and then the pre-trained models were fine-tuned using the limited data on the target property. Inverting the trained forward models, they derived a backward model conditioned by a desired property requirement. By solving this inverse problem, materials that exhibit the desired properties were computationally created. (Image credit: NIMS)

The collaborative research group includes Ryo Yoshida (Professor and Director of the Data Science Center for Creative Design and Manufacturing at the Institute of Statistical Mathematics, Research Organization of Information and Systems), Junko Morikawa (Professor at the School of Materials and Chemical Technology, Tokyo Institute of Technology), and Yibin Xu (Group Leader of Thermal Management and Thermoelectric Materials Group, Center for Materials Research by Information Integration, Research and Services Division of Materials Data and Integrated System, NIMS).

Their findings have been reported in the open-access journal npj Computational Materials. The scientists demonstrate that their ML technique, comprising “transfer learning,” facilitates the discovery of materials with preferred properties even from a very small data set.

The study was based on a data set of polymeric properties from PoLyInfo, the world’s biggest database of polymers housed at NIMS. Even with its large size, PoLyInfo does not have much data on the heat transfer properties of polymers.

To establish the heat transfer properties from the limited data available, ML models on substitute properties were pre-trained where adequate data were available on the associated tasks; these pre-trained models captured typical features applicable to the target task.

Re-purposing such machine-obtained features on the target task produced exceptional prediction performance even with the extremely small data sets, as if very skilled human experts can make rational inferences even for significantly less skilled tasks.

The researchers integrated this model with an exclusively designed ML algorithm for computational molecular design, which is known as the iQSPR algorithm developed earlier by Yoshida and his colleagues. Applying this method allowed the identification of numerous promising “virtual” polymers.

From this large group of options, three polymers were chosen based on their ability to be easily synthesized and processed.

Tests verified that the new polymers possessed a high thermal conductivity of up to 0.41 W/mK. This value is 80% higher than that of common polyimides, a class of frequently used polymers that have been manufactured in large scale since the 1950s for applications spanning from fuel cells to cookware.

By confirming the heat transfer properties of the computationally engineered polymers, the research signifies an important breakthrough for rapid, economical, ML-supported techniques for materials design. It also shows the team’s joint know-how in data science, organic synthesis, and innovative measurement technologies.

Yoshida states that several aspects are yet to be explored, such as “training” computational systems to function with limited data by incorporating more appropriate descriptors.

Machine learning for polymer or soft material design is a challenging but promising field as these materials have properties that differ from metals and ceramics, and are not yet fully predicted by the existing theories.

Ryo Yoshida, Professor and Director, Data Science Center for Creative Design and Manufacturing, Institute of Statistical Mathematics, Research Organization of Information and Systems

The research is a starting point for finding other advanced materials.

We would like to try to create an ML-driven high-throughput computational system to design next-generation soft materials for applications going beyond the 5G era. Through our project, we aim to pursue not only the development of materials informatics but also contribute to fundamental advancement of materials science, especially in the field of phonon engineering.

Junko Morikawa, Professor, School of Materials and Chemical Technology, Tokyo Institute of Technology