Aug 6 2019

Every living organism relies on enzymes—molecules that boost up biochemical reactions vital for life.

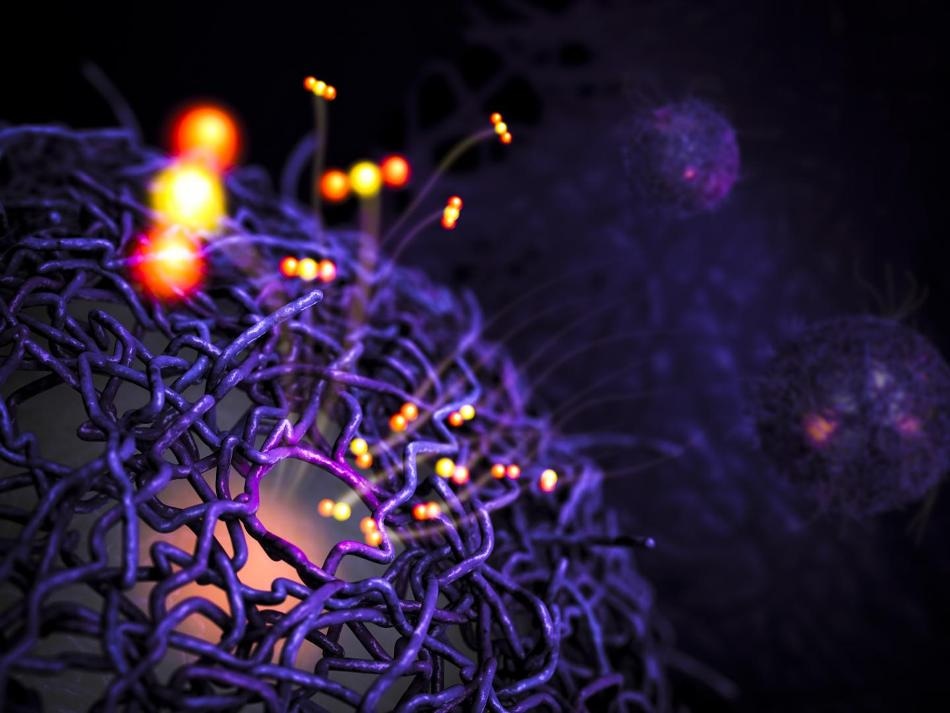

Scientists have invented an enzyme-like catalyst made of soft polymers (purple) and a hard palladium core (pink).When heated, the palladium chemically converts molecules of oxygen and carbon monoxide (yellow and orange) into carbon dioxide. The reaction stops when the polymers are saturated with carbon dioxide, a strategy used by living enzymes. Research is underway to develop catalysts that convert natural gas to methanol at low temperatures. (Image credit: Gregory Stewart/SLAC National Accelerator Laboratory)

Scientists have invented an enzyme-like catalyst made of soft polymers (purple) and a hard palladium core (pink).When heated, the palladium chemically converts molecules of oxygen and carbon monoxide (yellow and orange) into carbon dioxide. The reaction stops when the polymers are saturated with carbon dioxide, a strategy used by living enzymes. Research is underway to develop catalysts that convert natural gas to methanol at low temperatures. (Image credit: Gregory Stewart/SLAC National Accelerator Laboratory)

Researchers have spent several years attempting to produce artificial enzymes that can crank out important chemicals and fuels at an industrial scale with performance matching their natural counterparts.

Scientists from Stanford University and SLAC National Accelerator Laboratory have created a synthetic catalyst that synthesizes chemicals almost similarly the way enzymes perform in living organisms.

In a research reported in the August 5th, 2019, issue of Nature Catalysis, the scientists state their discovery could result in industrial catalysts that can produce methanol using minimal energy and at a reduced cost. Methanol has a range of applications, and there is an increasing requirement for its use as a fuel with lower emissions when compared to traditional gasoline.

We took our inspiration from nature. We wanted to mimic the function of natural enzymes in the laboratory using artificial catalysts to make useful compounds.

Matteo Cargnello, Senior Author and Assistant Professor, Chemical Engineering, Stanford University

To perform the experiment, the scientists developed a catalyst composed of nanocrystals of palladium, a precious metal, embedded in porous polymer layers modified with unique catalytic properties. The majority of protein enzymes present in nature also have trace metals, such as iron and zinc, embedded in their core.

The scientists were able to detect trace palladium in their catalysts using electron microscopic imagery by co-author Andrew Herzing of the National Institute of Standards and Technology.

Model Reaction

We focused on a model chemical reaction: converting toxic carbon monoxide and oxygen into carbon dioxide (CO2). Our goal was to see if the artificial catalyst would function like an enzyme by speeding up the reaction and controlling the way CO2 is produced.

Andrew Riscoe, Study Lead Author and PhD Student, Stanford University

To reveal it, Riscoe kept the catalyst in a reactor tube with a continuous flow of carbon monoxide and oxygen gas. Upon heating the tube to around 150 ○C (302 ○F), the catalyst started producing the desired product, carbon dioxide.

High-energy X-rays from the Stanford Synchrotron Radiation Lightsource (SSRL) at SLAC showed that the catalyst had characteristics comparable to those observed in enzymes: The palladium nanocrystals within catalyst were constantly reacting with oxygen and carbon monoxide to create carbon dioxide.

Moreover, some of the newly produced carbon dioxide molecules were getting caught in the outer polymer layers as they escaped from the nanocrystals.

“The X-rays showed that once the polymer layers were filled with CO2, the reaction stopped,” said Cargnello, an affiliate with the Stanford Natural Gas Initiative (NGI). “This is important, because it’s the same strategy used by enzymes. When an enzyme produces too much of a product, it stops working, because the product is no longer needed. We showed that we can also regulate the production of CO2 by controlling the chemical composition of the polymer layers. This approach could impact many areas of catalysis.”

The X-ray imaging was performed by study co-authors Alexey Boubnov, a Stanford postdoctoral scholar, and SLAC researchers Simon Bare and Adam Hoffman.

Making Methanol

The success of the carbon dioxide experiment has turned the attention of Cargnello and his teammates toward converting methane, the key component in natural gas, into methanol, a chemical extensively employed in textiles, plastics, and paints. Methanol has also been lauded as a cleaner and cheaper alternative to gasoline fuel.

The ability to convert methane to methanol at low temperatures is considered a holy grail of catalysis. Our long-term goal is to build a catalyst that behaves like methane monooxoygenase, a natural enzyme that certain microbes use to metabolize methane.

Matteo Cargnello, Senior Author and Assistant Professor, Chemical Engineering, Stanford University

At present, majority of the methanol is obtained in a two-step process in which natural gas is heated to temperatures of around 1,000 ○C (1,800 ○F). However, this energy-intensive process releases an enormous quantity of carbon dioxide, a powerful greenhouse gas that contributes to global climate change.

“An artificial catalyst that directly converts methane to methanol would require much lower temperatures and emit far less CO2,” Riscoe explained. “Ideally, we could also control the products of the reaction by designing polymer layers that trap the methanol before it burns.”

Future Enzymes

“In this work, we demonstrated that we can prepare hybrid materials made of polymers and metallic nanocrystals that have certain traits typical of enzymatic activity,” stated Cargnello, who is also affiliated with Stanford’s SUNCAT Center for Interface Science and Catalysis. “The exciting part is that we can apply these materials to lots of systems, helping us better understand the details of the catalytic process and taking us one step closer to artificial enzymes.”