Kistler's new Digital Transducer Interface (DTI) technology, a single end-to-end bus wiring system, is all that is required to take the measurement signal from every sensor to the data recorder.

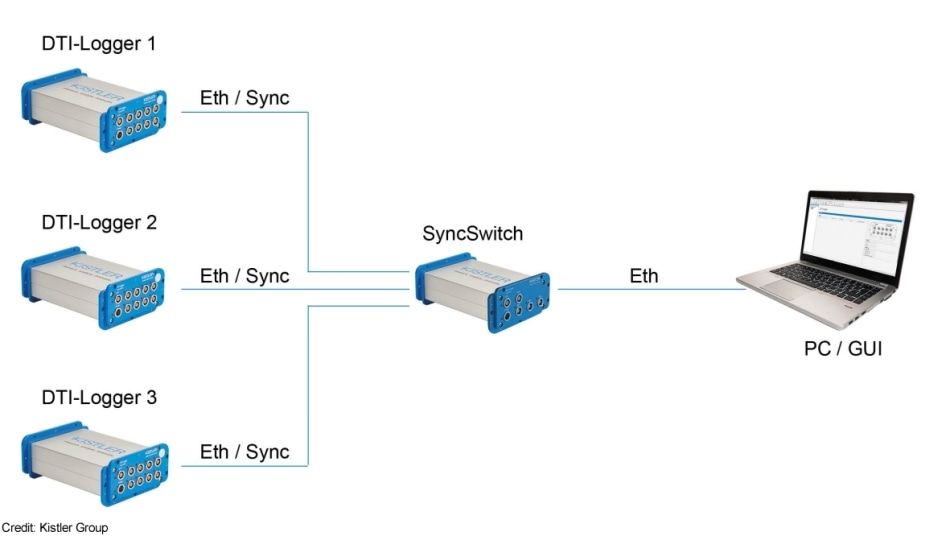

DTI converts each signal into a unique, time stamped digital output either directly in the Kistler DTI sensors or via suitable Kistler DTI A/D converters connected to any existing sensors. Kistler's DTI provides a single-cable solution that greatly simplifies vehicle dynamics and durability tests; a solution to meet future challenges. SyncSwitch, the latest addition to the Kistler DTI data logger system, has substantially increased capacity to 288 channels connected by a single Ethernet cable to a computer for real time, on-site evaluation.

DTI-Logger-Setup

DTI-Logger-Setup

Kistler is the only manufacturer to partner with automobile manufacturers by offering efficient test setups that feature additional benefits such as automatic sensor detection. For OEMs with limited resources available for the necessary tests, DTI is an efficient way of speeding up processes without compromising on precision, safety and reliability.

A simple test setup that saves time and money

The new system provides users with a complete measuring chain from sensor and the DTI-Logger to the user interface with KiCenter software. Typical applications include brake path measurement with straightforward ABS braking to DIN 70028 with many advantages including: fast, simple and clear wiring automatic sensor detection easy access to installed position, calibration values and physical parameters step-by-step configuration with KiCenter PC software interference free and synchronized data transmission via the new DTI logger with Ethernet connection

Even complex test setups require only one cable to configure the sensors, transmit and synchronize the measurement data, and provide the power supply to work efficiently and save time so test engineers can focus on the measurement tasks.

The full range of measuring tasks with just one setup

Comprehensive vehicle dynamics, durability and tyre tests involve a series of physical parameters such as acceleration, braking pressure, strain, steering forces and moments, side-slip angle and temperature. The substantially increased capacity of the new DTI bus system allows a measurement solution that is able to conveniently acquire and analyse all these key variables. The DTI-Logger plus the new SyncSwitch enables the data from a total of 288 sensors to be synchronized automatically and transmitted via a single Ethernet cable to a laptop or PC for on-site evaluation.

The new DTI technology from Kistler enables the use of a continuous bus system throughout the entire measuring. Only one cable is required for data transmission, synchronization, configuration and power supply, significantly reducing the wiring effort. This makes the actual measurement process extremely efficient and reduces sources of error in the application.