Aug 12 2019

Last year, in the United Kingdom, plastic microbeads were banned from toothpaste and shower gels; however, it could still be present in lipstick or sunscreen lotions.

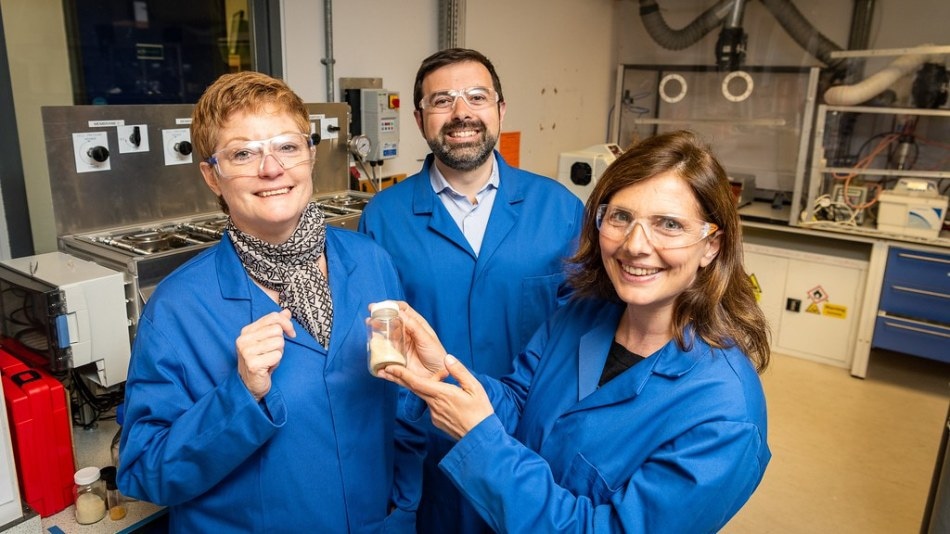

Janet Scott, Davide Mattia, and Giovanna Laudisio of Naturbeads. (Image credit: University of Bath)

Janet Scott, Davide Mattia, and Giovanna Laudisio of Naturbeads. (Image credit: University of Bath)

Start-up company Naturbeads, of the University of Bath, has collaborated with companies to substitute microplastics in these products with biodegradable microbeads developed from cellulose.

Although plastic microbeads used in rinse-off products were recently banned in the United Kingdom, they are still present in several other personal care products such as sunscreen and cosmetics.

Every year, around 30,000 tons of microplastics from consumer products end up in the world’s oceans. This is equivalent to thrice the Great Pacific Garbage Patch, or the plastic pollution produced by five billion plastic bottles.

Some of these microplastics are consumed by marine life, passing up the food chain and finally arriving at one’s own plates.

With Naturbeads’ biodegradable alternative to plastic microbeads, microplastic pollution in the oceans could be minimized, and thus traces from sunscreen, cosmetics, and other personal care products do not end up in the fish fingers.

The technology to produce the cellulose microbeads was engineered in 2017 at the University of Bath by Professors Janet Scott and Davide Mattia from the Centre for Sustainable Chemical Technologies.

In 2018, they co-funded the spin-off company Naturbeads to commercialize the technology along with Dr Giovanna Laudisio, CEO of the company. Recently, Naturbeads received funding by a partnership between UK Research and Innovation (UKRI) and Sky Ocean Ventures (SOV), through the Plastic Research and Innovation Fund.

It will be awarded £582,842 to construct and test a scaled-up prototype rig for the manufacture of cellulose microbeads added to cosmetic and personal care products.

Despite some legislative bans, harmful plastic microbeads are still in a range of products and continue to leak into our environments. Finding equivalent replacements to these types of low-cost plastics has been a challenge for industry.

Jamie Rowles, Head of Investment, Sky Ocean Ventures

Rowles continued, “By investing in Naturbeads, we are able to support a highly innovative technology and a passionate entrepreneurial team that is aiming to provide a biodegradable alternative that can perform like plastics and ensure the many products do not leave harmful residues in our environments for longer than nature intended.”

Our microbeads are produced using cellulose, the most abundant bio-material on Earth, and what plants and trees are made of. We are excited to see our technology deployed commercially and to contribute to reducing plastic pollution in our oceans.

Davide Mattia, Co-Founder of Naturbeads and Professor, Centre for Sustainable Chemical Technologies, University of Bath

The biodegradable microbeads are created using a cellulose solution, which is pushed through tiny holes in a tubular membrane, producing spherical droplets of the solution that are washed away from the membrane using vegetable oil. The beads are subsequently gathered, set, and isolated from the oil before use.

The prototype rig in this study will be employed to manufacture kilogram-scale cellulose microbead samples. These will be sampled to firms in the cosmetic and personal care industry to be tested in formulations.

We are thrilled to start our first project thanks to an Innovate UK grant and the support of an investor like Sky Ocean Ventures that shares our mission of reducing plastic pollution and understands the challenges of a deep tech start-up like Naturbeads.

Giovanna Laudisio, CEO and Co-Founder, Naturbeads

Biodegradable alternative to replace microplastics in cosmetics and toiletries

Naturbeads creators explain the biodegradable microplastic alternative. (Video credit: University of Bath)