With advancements in science and technology, the medical field has undergone a significant transformation, particularly in the area of implants and bio-integrated devices. Biodegradable materials are being extensively studied for their potential to eliminate the need for re-surgery to remove implants once they have reached the end of their lifespan.1

Image Credit: Monstar Studio/Shutterstock.com

What are Biodegradable Metallic Materials?

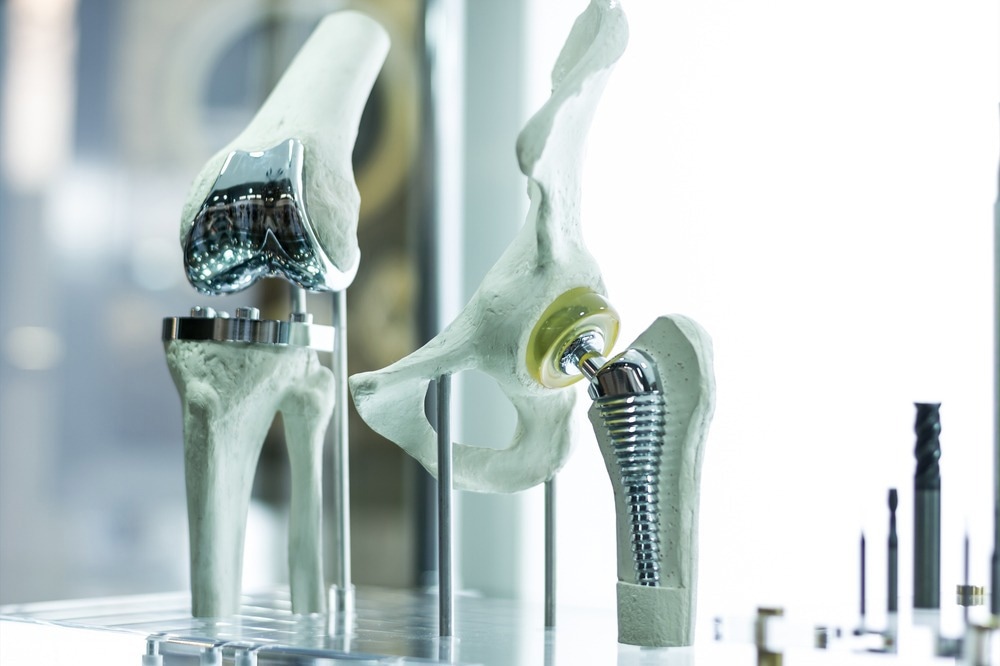

Biodegradable materials (BMs) have been a priority for temporary biomedical implants over the past twenty years. These materials, including magnesium, zinc, and iron alloys, are designed to dissolve progressively in the human body after supporting tissue healing. Compared to polymer counterparts, BMs offer higher mechanical strength and perform better as cardiovascular stents and bone implants.2

BMs are favored in biomedical implants over non-degradable metals like stainless steel and titanium alloys. They are instrumental in orthopedic, prosthodontic, and other bone tissue repair and replacement applications. Their unique physical and mechanical characteristics—such as an elastic modulus similar to human cortical bone, high specific strength, and low density—make them an excellent choice.3

Traditional metals must be surgically removed after the recommended healing period, causing discomfort and additional costs. These metals are also much stiffer than human bone, which can complicate the treatment of certain fractures. BMs address these issues effectively, promoting accelerated healing and bone growth.

Advantages and Applications in Medicine

Biodegradable metals and their alloys have gained popularity in biomedical applications due to their unique properties and benefits over traditional materials.

Magnesium Alloys

Magnesium (Mg)-based alloys are especially promising for orthopedic use. Mg has an almost identical Young’s modulus and matches the anisotropic properties of human cortical bone. Additionally, it shows high osteopromotive and biocompatible responses while degrading in the body. Due to its high availability, Mg is widely used in medical applications.

Mg alloys offer superior biocompatibility compared to bio-polymers and outperform bio-ceramics, which have lower mechanical strength for bone implants.4 They are easy to sterilize due to their surface quality, stiffness, and plasticity. Moreover, the by-products of Mg alloys and implants, particularly Mg ions, are non-toxic and safe, possessing unique osteopromotive properties.

Zinc Alloys

Zinc (Zn) is another important biodegradable metal known for its high biocompatibility and abundance in the human body.

Zn2+ is the second most abundant element in the body, mainly found in bones and muscles. Its physical and mechanical properties align well with human bones, making it more compatible than stainless steel and titanium.

Zinc has shown great potential for degradable metallic bio-resorbable stents. Numerous studies have evaluated its bioactive effects, cytocompatibility, and corrosion behavior.5

In several in-vivo tests, zinc has demonstrated good hemocompatibility, strong anti-atherogenic properties, and no toxicity to endothelial cells. Pure Zn stents implanted in the abdominal aortas of rabbits did not cause severe inflammatory responses, thrombosis, platelet aggregation, or intimal hyperplasia. The stents maintained their mechanical integrity and allowed normal cardiovascular functions.6

In another study, Zn-0.8Cu alloy stents implanted in coronary arteries for two years showed no thrombosis or inflammation. To address any limitations, surface modification techniques have been used to improve the mechanical properties of Zn-based biomaterials without affecting their biocompatibility or core matrix properties.

Iron Alloys

Iron has been widely used as an engineering material due to its excellent machinability and cost-effectiveness. These features make iron-based materials a great option for developing biodegradable materials for medical applications.

Iron is used in bone implants for surgeries, intravascular stents, and scaffolds in bone tissue engineering. Fe-based materials in scaffolds create good conditions for tissue repair. Due to their excellent biodegradability and mechanical strength, iron-based porous scaffolds are primarily used for repairing hard tissues like bones, addressing the limitations of non-degradable polymer scaffolds.

Researchers conducted an experimental study and found that pure industrial-grade Fe had no cytotoxicity and exhibited excellent hemocompatibility and biocompatibility.

Another study investigated the in vitro cytotoxicity of nitride iron stents, discovering that oxygen availability and the extraction medium were important during incubation and extraction. Extracts with high iron concentrations showed no cytotoxicity to L929 cells.7

However, the alloying elements affected the biocompatibility of Fe alloys. In short, iron itself is among the top candidates for the application of BMs in medical implants and devices.

Challenges and Innovations

Biodegradable metals (BMs) are considered a top priority for biomedical applications; however, several limitations hinder their commercialization.

Corrosion resistance and cytocompatibility are crucial for the safe performance of bio-implants in in-vivo conditions.

Mg and Mg-based materials in orthopedic implants exhibit a higher corrosion rate than biosafety limits. When the corrosion medium contains chloride above 3 mM/L, magnesium transforms into magnesium chloride (MgCl2), which is highly soluble in aqueous solutions and promotes further corrosion in the human body.8

Advanced Coating

To enhance the corrosion resistance of magnesium, fluoride coatings have gained significant research interest. Fluoride-coated magnesium alloys have shown excellent corrosion resistance in in vitro immersion experiments.

Researchers created screws and tensile specimens from magnesium alloys, using HF to acquire HF-coated samples. After immersing the bare and HF-coated magnesium alloy samples in a simulated body fluid (HBSS), the immersed screw samples were examined with scanning electron microscopy (SEM) and mass loss detection.9

The results indicated that the corrosion rate of the coated screw samples was only one-quarter of that of the uncoated samples due to the protection provided by the uniform and dense MgF2 coating.

3D Printing and Additive Manufacturing

Additive manufacturing, particularly 3D printing, offers a promising method for fabricating corrosion-resistant implants with BMs. While 3D printing has revolutionized many fields, including biomedical applications, research on manufacturing BMs using 3D printing remains limited. To advance this technology, several key challenges need to be addressed.

These challenges include reducing surface roughness, controlling residual stress, improving the interaction between the electron beam and metal powders, eliminating internal structural defects, and enhancing accuracy and efficiency. Additionally, improvements are needed in the equipment used for 3D printing metal fabrication.

Despite these challenges, 3D printing holds great potential for addressing complex clinical problems and ensuring the effectiveness of BMs for medical implants and devices.10

More from AZoM: What is Thermal Runaway?

References and Further Reading

- FZU Institute of Physics of the Czech Academy of Sciences (2021). Biodegradable metal materials for medical applications. [Online] FZU. Available at: https://www.fzu.cz/en/interships-and-topics-for-students/biodegradable-metal-materials-medical-applications (Accessed on June 1, 2024)

- Han, H., et al. (2020). Biodegradable magnesium alloys promote angio‐osteogenesis to enhance bone repair. Advanced science. doi.org/10.1002/advs.202000800

- Sangeetha, K. (2023). Degradable metallic biomaterials for cardiovascular applications. Fundamental Biomaterials: Metals. doi.org/10.1016/B978-0-08-102205-4.00013-1

- Yao, R. et al. (2023). Biodegradable porous Zn-1Mg-3βTCP scaffold for bone defect repair: In vitro and in vivo evaluation. Journal of Materials Science & Technology. doi.org/10.1016/j.jmst.2023.03.055

- Guan, Z., et al. (2020). Novel zinc/tungsten carbide nanocomposite as bioabsorbable implant. Materials letters. doi.org/10.1016/j.matlet.2019.127282

- He, J., et al. (2020). A study of degradation behaviour and biocompatibility of Zn—Fe alloy prepared by electrodeposition. Materials Science and Engineering: C. doi.org/10.1016/j.msec.2020.111295

- Lin, W., et al. (2017). Long-term in vivo corrosion behavior, biocompatibility and bioresorption mechanism of a bioresorbable nitrided iron scaffold. Acta biomaterialia. doi.org/10.1016/j.actbio.2017.03.020

- Khan, A., et al. (2023). Recent advances in biodegradable metals for implant applications: exploring in vivo and in vitro responses. Results in Engineering. doi.org/10.1016/j.rineng.2023.101526

- Zhai, C., et al. (2022). Fluoride coatings on magnesium alloy implants. Bioinorganic Chemistry and Applications. doi.org/10.1155/2022/7636482

- Liang, W., et al. (2023). Recent advances in 3D printing of biodegradable metals for orthopaedic applications. J Biol Eng. doi.org/10.1186/s13036-023-00371-7

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.