Covestro has announced new Makrolon® DQ (Diffusion Quality), a tailor-made product range for large diffusers of LED lamps and lights. Covestro will present its latest range at this year's LpS (LED professional Symposium +Expo).

New Polycarbonate Diffuser Grades of the Makrolon® DQ Range Enable an up to 10% Higher Light Transmission

New Polycarbonate Diffuser Grades of the Makrolon® DQ Range Enable an up to 10% Higher Light Transmission

Potential applications include, among others, ceiling and tri-proof or diffuser lights that must be waterproof, dustproof, impact-resistant and corrosion-resistant at the same time. There is great potential for use, for example, with lamps that are highly resistant to vandalism and must have an IK impact resistance of over 6.

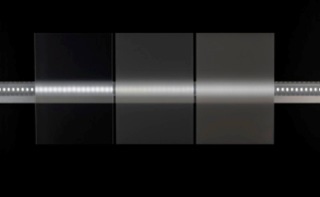

Makrolon® DQ (Diffusion Quality) Product Range

The first representatives of the product range are the Makrolon® DQ5122, DQ5142 and DQ5162.

“Compared with standard diffuser types of polycarbonate, the three materials exhibit up to 10% higher light transmission with the same diffuser effect. This gives manufacturers of LED lighting elements the opportunity to significantly increase either the brightness or the luminous efficacy and thus the energy efficiency of their lights,” explains Dr. Fabian Grote, Expert for LED Applications in the Polycarbonates Segment at Covestro.

Skipping a Generation of LEDs

“Our new product range has the potential to skip one LED generation in terms of luminous efficacy without this being reflected in significantly higher LED prices,” Grote continues.

- The new product range is characterized by excellent processability.

- The three construction materials, for example, are as easy-flowing as or even more easy-flowing than the Makrolon® 2207 and 2407 grades developed for diffusers. This translates into short cycle times.

- In addition, complex component geometries can be injection molded without difficulty.

- Makrolon® DQ5122, DQ5142 and DQ5162 are optimized for half value angles of about 19°, 43° and 56°, respectively.

The new compounds have already proven their suitability for series production: The replacement of Makrolon® 2207 with Makrolon® DQ5122 in the manufacture of a diffuser for an LED light, for example, resulted in a 6% higher luminous efficacy with comparable economic processing.

All three new materials, with their mechanical, rheological, thermal and fire characteristics, have Yellow Card classification from Underwriters Laboratories Inc. (UL) in the United States.

New Highly Transparent Polycarbonates

Covestro will also be focusing on the new UV-stabilized and highly transparent polycarbonates Makrolon® LED5102, LED5202 and LED5302.

Due to their high transmittance of 90% and their permanently good heat and light resistance, they are ideal for manufacturing lenses and optics.

Grote: “With otherwise comparable properties, the three materials show differences in their flow behavior to give the designer and fabricator more leeway in the mechanical design of the component in question.”