Jan 20 2020

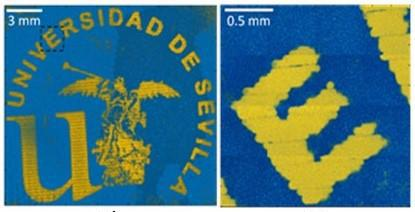

For the first time, a research team from the University of Seville, in association with the University of Nottingham, has successfully produced the first image of stabilized gold nanoparticles with biocompatible and biodegradable systems achieved with 3D-printing methods. The logo of the University of Seville was the image selected for this test.

This achievement will have applications in the pharmaceutical industry, such as in the preparation of biocompatible biosensors based in gold, which have already been shown to be effective in the detection of carcinogenic cells and tumor biomarkers. Image Credit: Universidad de Sevilla.

This achievement will have applications in the pharmaceutical industry, such as in the preparation of biocompatible biosensors based in gold, which have already been shown to be effective in the detection of carcinogenic cells and tumor biomarkers. Image Credit: Universidad de Sevilla.

This latest breakthrough will find use in the pharmaceutical sector, for example, to prepare gold-based biocompatible biosensors, which have earlier been demonstrated to be effective in detecting tumor biomarkers and carcinogenic cells.

In the recent past, additive manufacturing, generally known as 3D printing, has been identified as a perfect method for applications needing intricate personalization or geometries. When compared to traditional production techniques, 3D printing manufacturing based on layers can reduce the costs associated with general small-batch manufacturing products.

This aspect has triggered an interest in the pharmaceutical sector, which has noticed a gateway to the complete personalization of treatment in this kind of technology.

The study focused on the method known as inkjet printing. This technique provides benefits like high resolution and also offers the possibility to print more than one material at the time of the same printing process. With the help of this method, the scientists have suggested the manufacturing of systems that can possibly be utilized as personalized biosensors depending on gold’s biocompatibility and conductivity.

At present, prevalent gold inks intended for inkjet printing are based on this metal’s nanoparticles. However, the gold inks are highly unstable since they easily bind together and cannot be printed with ease. Because of that reason, the development of easy-to-print, stale gold inks has been very useful.

The research team, headed by Ana Alcudia Cruz of the Department of Organic and Pharmaceutical Chemistry from the Pharmacy faculty at the University of Seville, teamed up with the group guided by Rafael Prado Gotor of the Department of Physical Chemistry, from the Chemistry Faculty at the University of Seville, and also by Ricky Wilman, from the University of Nottingham based in the United Kingdom.

The researchers were able to utilize polymers, or polyurethanes, that have a comb structure; these polymers were developed by the researchers themselves to produce small gold nanoparticles. These nanoparticles have excellent stability that has been tested over time.

In this context, several polymers were made from arabinose, a kind of sugar that is easily available in nature and gives complete biodegradability and biocompatibility to the developed material. As a result, polluting residues created by the conventional oil-derived polymers are prevented.

This kind of polymer has been used for preparing gold nanoparticles for the first time. Such nanoparticles, acquired from three types of different chemically functionalized polymers, were found to be adequately small (a maximum dimension of 10 nm) to be printed in inkjet printing and remained stable for a minimum of six months.

After testing the printability of each ink, the ink that exhibited the optimal balance of the properties was chosen and used to print the logo of the University of Seville. In the image, achieved using the TOF-SIMS method, the gold can be seen (shown in yellow), forming the logo’s outline, on a polymer background (shown in blue).

This is the first-ever image of gold nanoparticles that were stabilized with biocompatible and biodegradable systems realized with 3D-printing methods.