Feb 11 2020

Worldwide, the need for efficient solar energy harnessing to ensure a highly sustainable future is being accepted more and more. A new class of solar cells developed using perovskites—materials that have a specific crystal structure—is now competing with traditional silicon materials to fulfill the demands in this area.

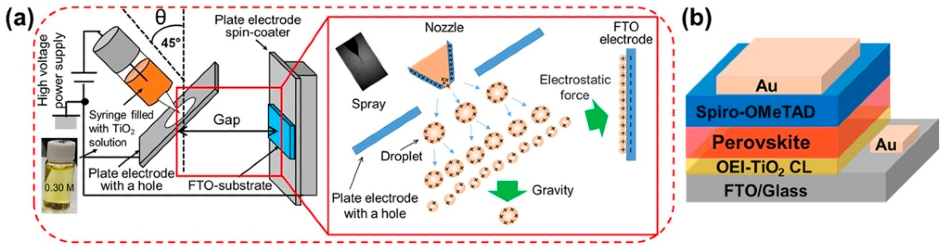

Schematic illustration of (a) the OEI setup used to pattern the TiO2 CL on FTO glass substrates and (b) the device structure of OEI-TiO2 CL-based PSCs. Image Credit: Kanazawa University.

Schematic illustration of (a) the OEI setup used to pattern the TiO2 CL on FTO glass substrates and (b) the device structure of OEI-TiO2 CL-based PSCs. Image Credit: Kanazawa University.

Continual optimization of perovskite solar cells (PSCs) has been performed to meet their commercial potential. Led by scientists from Kanazawa University, a research team has now developed a new and simple oblique electrostatic inkjet (OEI) strategy for depositing a titanium oxide (TiO2) compact layer on FTO-pattern substrates.

This technique avoids the need for a vacuum environment as an electron transport layer (ETL) for improving the efficiency of PSCs. The study outcomes have been reported in Scientific Reports.

The PSCs include a stack of distinct component layers with a particular role to play. The ETL is usually formed of TiO2 and allows the transport of charge-carrying electrons to the electrodes while preventing the transport of holes, which tend to recombine with electrons to arrest their flow. Therefore, it is crucial to establish a complete TiO2 layer with the accurate thickness, uniform and free of flaws, to make efficient solar cells.

A majority of the TiO2 deposition approaches developed so far have related drawbacks, like poor reproducibility or coverage, or being inappropriate for scale-up. They might also necessitate difficult preparation conditions, like a vacuum. The research team has reported a simple, economical OEI technique that enables the deposition of a compact layer without the need for a vacuum.

Our technique can produce uniform electron transport layers whose thickness can be varied by controlling the deposition time. Solar cells made using our approach had power-conversion efficiencies of up to 13.19%, which, given the other advantages of our technique, is very promising for scale-up and commercialization.

Dr Md. Shahiduzzaman, Study Lead Author and Assistant Professor, Kanazawa University

As part of the new technique, positively charged droplets that have an affinity to a negatively charged surface are deposited. Earlier studies that adopted the same electrostatic techniques achieved lower power-conversion efficiencies because the droplets formed a stack on the surface due to gravity.

The effect of gravity was eliminated by introducing an oblique angle into the process—by spraying the TiO2 precursor at an angle of 45° to the surface. This resulted in the deposition of a highly uniform layer.

According to Dr Shahiduzzaman “An optimum ETL deposition method must offer a number of properties to result in a high efficiency solar cell.”

The ability to control the layer thickness and achieve a uniform, reproducible layer at low cost, without the need for a vacuum, provides a unique package of advantages that has not been reported to date. We hope that these properties will lead to effective and commercially relevant scale-up that will contribute to the drive towards cleaner energy worldwide.

Dr Md. Shahiduzzaman, Study Lead Author and Assistant Professor, Kanazawa University

This study was funded by the Research and Study Project of Tokai University General Research Organization and by a grant from the Mitani Foundation for Research and Development.