Image Credit: Nordroden/Shutterstock.com

Element Materials Technology (Element) has invested in a dedicated powder characterization site for additive manufacturing at its Huntington Beach, California laboratory.

In response to the growth in the 3D printing industry and increasing customer demand, Element has invested in a full suite of powder characterization testing to expand its current offering and provide customers with more technically demanding options.

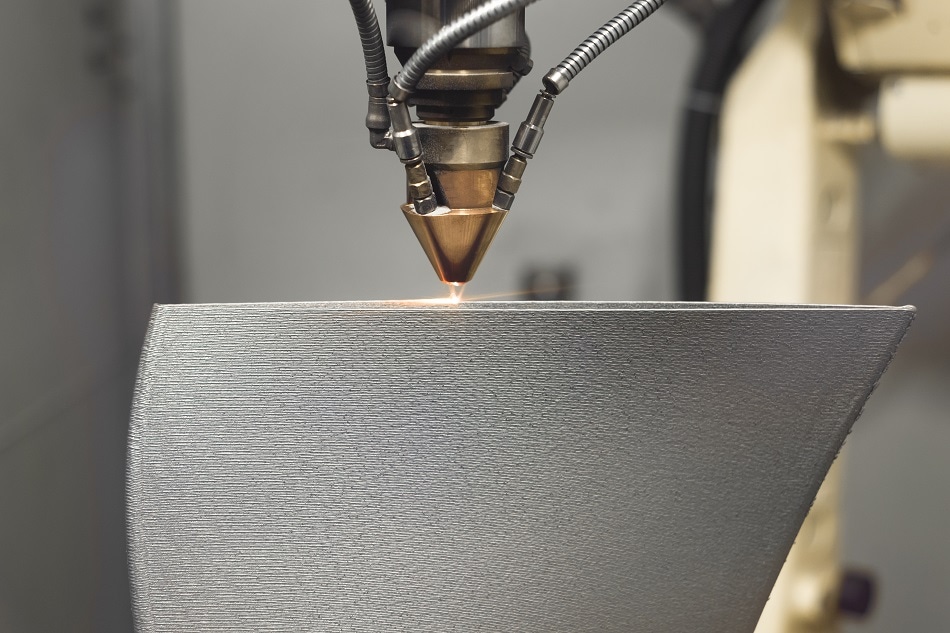

Powder characterization is the front end of the 3D printing manufacturing process. It is required to ensure powder is authentic, pure, uniform and ready for processing and once printed, Element can also perform mechanical, dynamic, chemical and metallurgical testing on the materials that are produced.

The new tests at Huntington Beach include chemical composition analysis, powder sieve analysis, particle size distribution, flow rate, apparent density, tap density and gas pycnometry.

3D printing is well beyond an emerging market now, and is an increasingly important space for us to be working and investing in. Powder characterization has applications in multiple industries, including aerospace and medical devices, which are key sectors for Element. Broadening our offering ensures that we are at the forefront of technical advancement, and we can provide a full suite of services to both new and existing customers.

Rick Sluiters, EVP Aerospace, Element

Element’s Huntington Beach laboratory has been providing materials testing and consulting for customers worldwide since 1982. With over 250 multidisciplinary, engaged experts and state-of-the-art equipment, the laboratory supports a diverse range of quality requirements, from routine high-volume testing to complex materials analysis and failure investigations.

The laboratory's Nadcap-accredited testing capabilities supply the foundation for quality control and product improvement for many industries along the North American West Coast, including aerospace, military, nuclear, and medical manufacturing.