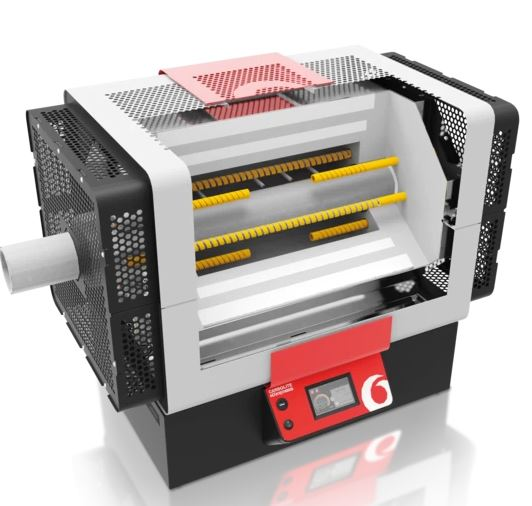

Image Credit: CARBOLITE GERO Ltd.

Over the last 18 months, Carbolite Gero’s team of product specialists, industrial designers and skilled engineers have worked tirelessly to develop a versatile new range of tube furnaces.

These new tube furnaces boast high-quality heating elements and an innovative thermal insulation design which is the result of over 80 years of experience in thermal engineering.

The new tube furnaces deliver unrivalled performance with rapid heating & cooling as well as outstanding temperature uniformity. They benefit from significantly reduced power consumption over previous models and they can all be used either horizontally or vertically. Their solid construction and high-quality components ensure users will benefit from a significant return on their investment.

The new tube furnaces have been designed with total flexibility in mind. Slide-in accessory work tubes and the use of tube adapters allow a single furnace to accommodate a variety of tube diameters, whilst the work tubes themselves can easily be exchanged to meet the different physical or chemical requirements of a process.

Optional work tube packages enable users to equip their tube furnace for operation under vacuum or with a modified gas atmosphere. Our gas packages optimise the inert atmosphere inside the work tube. Allowable gases are: nitrogen, argon or carbon dioxide. Should you require hydrogen a Carbolite Gero gas safety system will also be needed for safe operation.

Whether you require a single or three-zone universal tube furnace (TF Range), a split tube single or three-zone furnace (TS Range) or a gradient tube furnace (TG Range) with two or three heated zones then the new comprehensive range of tube furnaces from Carbolite Gero are outstanding candidates for your organization.