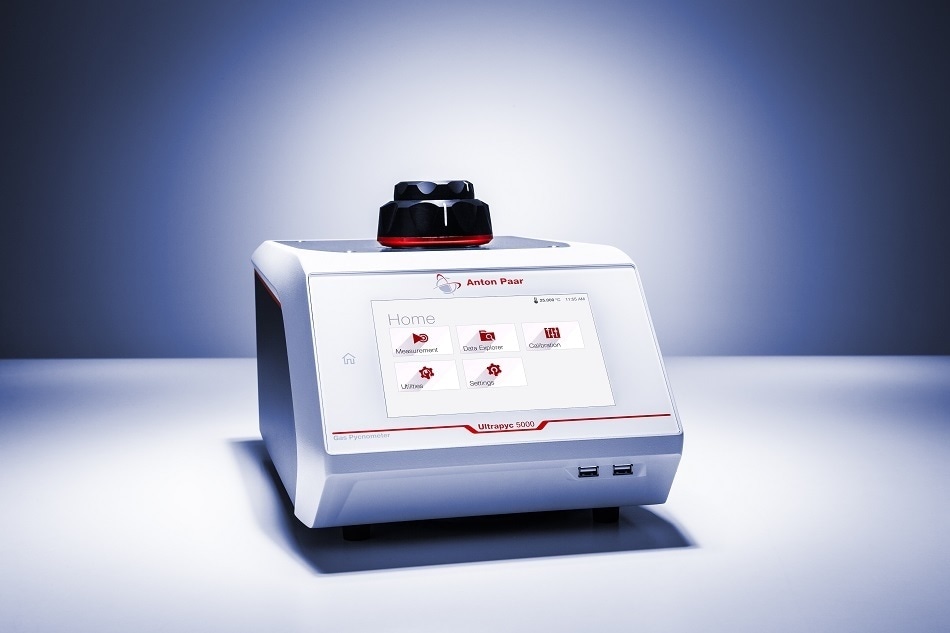

Anton Paar presents the new generation of the renowned and proven Ultrapyc gas pycnometers. The features incorporated into this new and enhanced version of Ultrapyc make it the most accurate and precise automated gas pycnometer for the widest range of sample sizes on the market today. The series features an intuitive user interface, built-in Peltier controller with the widest available temperature range (from 15 °C to 50 °C), and many more features making true density measurement ultra-simple and ultra-precise.

Typical Applications

Gas pycnometers have long been recognized as the instruments of choice to accurately measure the true density of solid materials by employing Archimedes’ principle of fluid displacement and Boyle’s law of gas expansion. Just a few of the fields of applications where it is important to know the true density include mining, oil exploration, cements, ceramics, additive manufacturing, catalysts, metallurgy, polymers and foams, pharmaceuticals and a whole host of other powder materials.

Four Models to Cover a Variety of Sample Amounts and Material Types

Ultrapyc 3000, Ultrapyc 5000, Ultrapyc 5000 Foam, and Ultrapyc 5000 Micro all feature an intuitive user interface for quickly navigating, adjusting settings, beginning, pausing, and stopping measurements, as well as accessing all the required work steps. With their multiple built-in reference chambers and the self-aligning TruLock lid closure system, they provide accurate measurements over and over again with any of the supplied sample cells. With a choice of expansion direction, including the new PowderProtect system for measuring very fine powders, and built-in temperature control, all three Ultrapyc 5000 models provide the ultimate flexibility in sample measurement capabilities. The new Ultrapyc series represents a significant step forward in user-friendliness and makes accurate solid density analysis easier than ever before.