Polyglass U.S.A., Inc., a leading manufacturer of roofing and waterproofing systems, has enhanced the performance of its self-adhered mod bit roofing membranes. Used to design durable low-slope roof systems, the upgraded membranes install faster and cleaner resulting in labor and time savings.

A pioneer of self-adhered roofing technology, Polyglass manufactures a full line of multi-surface membranes that do not require a torch or hot asphalt during application. With its cutting-edge ADESO® Dual Compound Self-Adhered Technology, the company produces membranes with APP or SBS modified asphalt compounds with a top layer acting as the weathering surface and an aggressive self-adhered compound on the bottom layer.

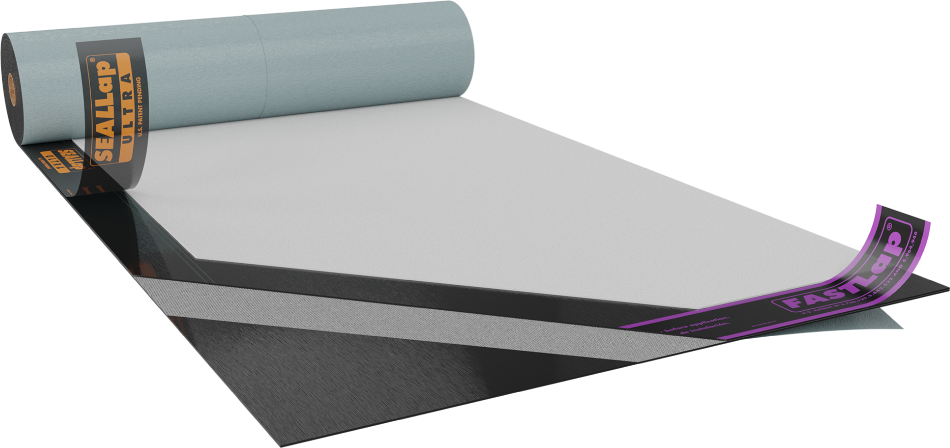

Polyglass recently added a new labor saving feature, patent-pending SEALLap® Ultra, to promote instantaneous watertight side lap seams in all the Self-Adhesive Membranes. SEALLap® Ultra, is a self-adhered compound applied on the side lap area to increases the bond strength and long-term adhesion of the seams. Our ADESO products now offer a side-lap with greater shear strength than any other assembled mod bit roof system – torch, mop, cold or other non-PG self-adhered. When compared to similar mod- bit membranes and traditional application methods.

Additionally, to reduce installation time, Polyglass developed FASTLap® — a granule-free end lap that installs hassle-free. FASTLap® is designed to promote watertight end laps and enables easy and safe installs.

“We are proud of the advancements made to the self-adhered products,” says Scott Lelling, director of strategic marketing. “Polyglass continues to invest in technology and discover better ways to roof, passing on savings to the roofing contractor while helping them to meet the needs of their customers.”

Visit Polyglass.us for more information about self-adhered membranes for cool roofs, cold temperature installs and more.