Aug 18 2020

Silk is spun by silkworms and spiders, but human engineers are still clueless about how to reproduce this strong yet fine fiber artificially.

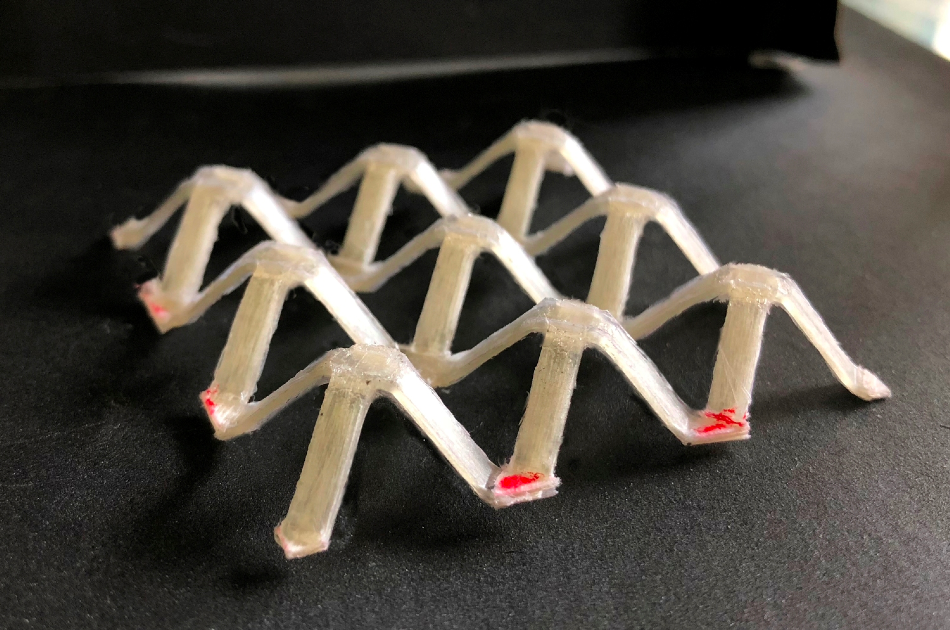

Combining silk fabric with epoxy creates laminates that can be formed into shapes, like the structure above, for medical uses. Image Credit: Jiao Wen and Juan Guan.

Combining silk fabric with epoxy creates laminates that can be formed into shapes, like the structure above, for medical uses. Image Credit: Jiao Wen and Juan Guan.

A group of researchers has combined silk, which can be used safely in the human body, with artificial compounds. This breakthrough has brought the team closer to producing novel implantable composite materials that have the best characteristics of both.

Promising applications, which are still decades away, may include replacements for the cartilage cushions in the knee or structures that keep bone in place following surgery.

The team will present the study results at the American Chemical Society (ACS) Fall 2020 Virtual Meeting & Expo. The meeting is being held through Thursday, August 20th, 2020. It includes over 6000 presentations on a variety of science-related topics.

Silk has great potential for use in biomedical applications. Silk is versatile, and the human body tolerates it quite well, and can even degrade and absorb it.

Juan Guan, PhD, Study Principal Investigator, Beihang University

Silk has been used in medicine for a long time. Records dating back almost 2000 years have shown that ancient physicians stitch up their patients with fibers woven by silkworms. At present, surgeons use silk sutures to complete specific surgeries such as those on the eye.

Using the combination of synthetic polymers and silk, Guan and her collaborators from Beihang University are looking for ways to create new, versatile materials for use in the field of medicine and, perhaps, other fields.

Although other scientists have already produced silk-based composite materials, they have often worked with the primary protein in silk or short fibers.

But Guan mainly focuses on silk fabric that is spun from one long thread. The cocoons of silkworms can contain fibers that measure almost 5000 ft in length. When these fibers are utilized as a whole in fabrics, they can distribute the mechanical stress more effectively when compared to a range of discrete, shorter ones, Guan added.

In their analyses, Guan’s research team employed silk obtained from the common and domesticated silkworm called Bombyx mori, and also used stronger and stretchier fibers obtained from the wild species called Antheraea pernyi.

The team then mixed this fabric with a polymer matrix, which is usually an epoxy used in adhesives. Collectively, the polymer and the fabric create a laminate—analogous to the long-lasting surface covering seen on certain furniture. This laminate can be subsequently cut into the shapes based on the team’s requirements.

According to Guan and her collaborators, these novel materials exhibit properties that could make them a better match for the tissues found inside the human body than the ones being utilized at present.

For example, the researchers are working with orthopedic physicians to create cage-like structures that momentarily keep the vertebrae in place as they combine following surgery; at present, metal is often used to perform this surgery.

The stiffness and hardness of silk composites are more compatible with bone, rendering them possibly more resilient but more comfortable when compared to metal structures, Guan added.

But challenges still exist. The inner side of the human body is known to be moist, which is a potential issue because silk is generally softened and weakened by water. In the latest experiments, Guan and her collaborators investigated how silk-epoxy composite materials are able to endure when subjected to humidity or when submerged in water.

If these materials had to be used alongside bone, they should be able to sustain a specific level of stiffness. These experiments demonstrated that while this feature was reduced under wetter conditions, the composite materials remained sufficiently stiff to work as implants, Guan noted.

Although the epoxy firmly binds to the silk fiber, it also has a major disadvantage: the human body cannot decompose the epoxy and absorb it, which means it would not be appropriate for implants meant to dissolve.

Therefore, Guan has started to work with biopolymers that, similar to silk, can be decomposed and absorbed by the body. But such composites have less internal cohesion when compared to those containing an epoxy.

The key question is how to make the interface between the biopolymer and the silk fabric more robust.

Juan Guan, PhD, Study Principal Investigator, Beihang University

The team is also searching for means to complement silk with other kinds of fibers. In yet another new study, the researchers introduced carbon fibers to the mix.

The notion of hybridizing silk with other fibers makes it possible to produce a rather nice spectrum of properties that you can optimize for a given application.

Robert O. Ritchie, PhD, Study Author

According to Ritchie, the author of the carbon fiber study, promising applications of these novel structural materials could be anywhere—within the human body, or even on airplane engines or in tennis rackets.

The team acknowledged funding and support from the Beijing Advanced Innovation Center for Biomedical Engineering and the Fundamental Research Funds for the Central Universities.