MSR-Electronic provides security against CO2 / C2H4 / C2H4O and O2 deficiency.

Copyright MSR-Electronic GmbH, Germany, graphic gas measurement in ripening chambers

Copyright MSR-Electronic GmbH, Germany, graphic gas measurement in ripening chambers

Fresh fruit and vegetables are alive and continue to breathe after the harvest thus leading to oxygen consumption and the formation of carbon dioxide and water vapour. Keeping products fresh means slowing down the ripening process while maintaining the quality of the product.

Supervised atmosphere during the preservation and ripening process of fruit and vegetables.

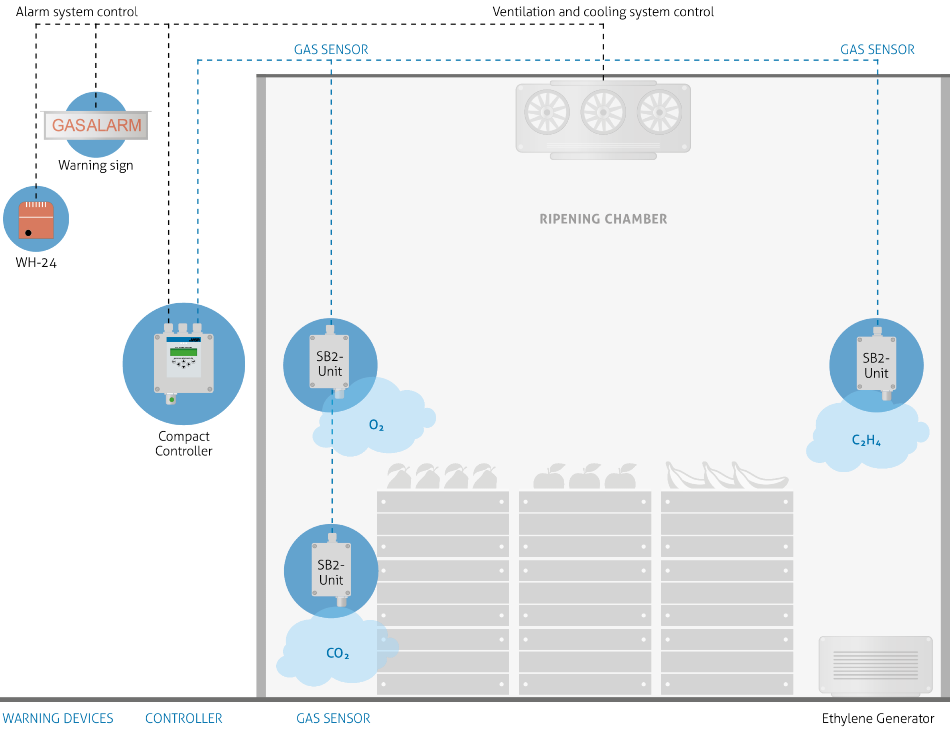

Irrespective of the modern technology of the ripening chambers, gas sensors are required for permanent monitoring of the different gas concentrations involved in the ripening process. The sensors, controllers and warning devices from MSR-Electronic protect people and equipment effectively and monitor the system as a central point of the entire process. With the help of modern communication technology, it is possible to react quickly.

Copyright MSR-Electronic GmbH, Germany, graphic gas measurement in ripening chambers

The control of the atmosphere consists largely in monitoring and adjusting the values of a few gases in the air: nitrogen, oxygen, CO2. In particular, by controlling the levels of nitrogen and oxygen, it is now possible to reduce the ethylene content which is naturally produced by the metabolic process of the fruit, which is the indication of the beginning of the ripening process.

The process of banana ripening is probably the best known and consists of introducing ethylene into the storage room at concentrations around 150–200 ppm to accelerate the natural ethylene production of the banana itself.

The Compactcontroller of the PolyGard®2 series from MSR-Electronic is designed for the connection of up to 10 gas sensors via its own field bus and is used to warn against various gases. It is therefore ideal for the application.

You will find important details in our application flyer for safe ripening chambers. Click here to download.

Information on further MSR products can be found here in the current online catalog or in the web shop: www.msr-24.com.