Sep 9 2020

The constituent particles in the electrodes of a lithium-ion battery are microscopic in nature, yet mighty.

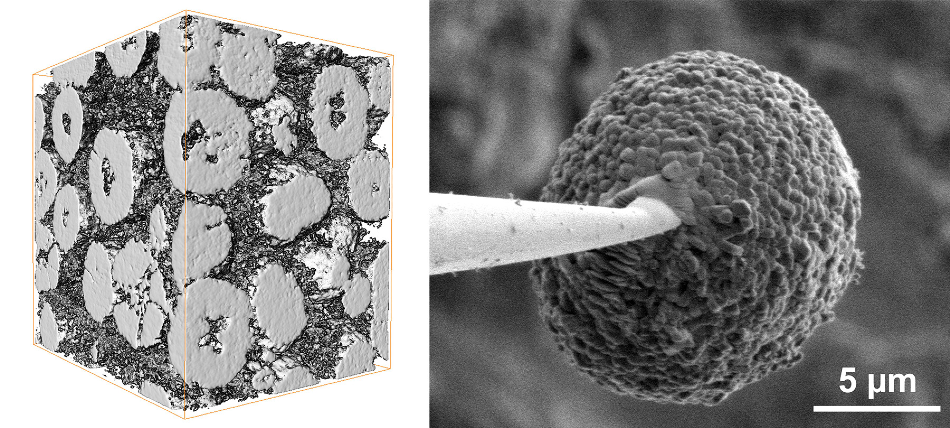

Images made with an X-ray microscope show particles within a nickel-rich layered oxide battery electrode (left). In a SLAC study, scientists welded a single charged particle to the tip of a tungsten needle (right) so they could probe its surface and interior with two X-ray instruments. The particle is about the size of a red blood cell. Image Credit: S. Li et al., Nature Communications, 2020.

Images made with an X-ray microscope show particles within a nickel-rich layered oxide battery electrode (left). In a SLAC study, scientists welded a single charged particle to the tip of a tungsten needle (right) so they could probe its surface and interior with two X-ray instruments. The particle is about the size of a red blood cell. Image Credit: S. Li et al., Nature Communications, 2020.

These particles govern how fast the battery charges and discharges, the amount of charge it can store, and its durability over time—all these factors are vital for high performance in an electronic device or electric vehicle.

The performance can be affected by chemical reactions and cracks on the surface of a particle, and the ability of the entire particle to absorb and discharge lithium ions also varies over time. Researchers have analyzed both; however, to date, both the interior and the surface of an individual particle have not been analyzed to see what happens if one impacts the other.

Led by Yijin Liu from the Department of Energy’s SLAC National Accelerator Laboratory, a team of researchers performed exactly that as part of a new study. The researchers attached a single battery cathode particle, with a size about that of a red blood cell, on a needle tip and investigated its surface and interior in three dimensions through two X-ray instruments.

They found that chemical changes and cracking on the surface of the particle differed much from one place to another and corresponded with regions of microscopic cracking deep within the particle that affected its capacity to store energy.

Our results show that the surface and the interior of a particle talk to each other, basically. Understanding this chemical conversation will help us engineer the whole particle so the battery can cycle faster, for instance.

Yijin Liu, Lead Scientist, SLAC

Liu led the study at the Stanford Synchrotron Radiation Lightsource (SSRL) at SLAC. The researchers reported the study results recently in the Nature Communications journal.

Damage both inside and out

In a lithium-ion battery, energy is stored and released by the movement of lithium ions through an electrolyte to and fro between two electrodes—the cathode and the anode. When the battery is charged, lithium ions plunge into the anode for storage. When the battery is used, the ions from the anode move into the cathode, generating a flow of electrical current.

Each electrode includes several microscopic particles, where each particle includes much smaller grains. Their chemistry and structure are crucial to the performance of the battery. During the charging and discharging of the battery, lithium ions tend to penetrate and move out of the spaces between the atoms of the particles, making them swell and shrink.

As time passes, this can lead to cracking and breaking of particles, which reduces their potential to absorb and release ions. Moreover, the particles tend to react with the surrounding electrolyte to develop a surface layer that inhibits the entry and exit of ions. When cracks form, the electrolyte tends to penetrate deeper and damages the interior.

The focus of this research was on particles developed using a nickel-rich layered oxide, which can technically store more charge compared to existing battery materials. Moreover, it contains less cobalt, which makes it less expensive and less ethically problematic, as cobalt mining in certain regions involves inhumane conditions, added Liu.

The study stumbled upon just one issue: The capacity of the particles to store charge fades faster during several rounds of high-voltage charging—the type used for quick charging of electric vehicles.

You have millions of particles in an electrode. Each one is like a rice ball with many grains. They’re the building blocks of the battery, and each one is unique, just like every person has different characteristics.

Yijin Liu, Lead Scientist, SLAC

Taming a Next-Gen Material

According to Liu, researchers have been exploring two fundamental strategies to reduce damage and to increase the performance of particles—forming a protective coating on the surface and packing the grains together in multiple ways to modify the internal structure. “Either approach could be effective, but combining them would be even more effective, and that’s why we have to address the bigger picture,” added Liu.

The X-ray experiments for investigating a single needle-mounted cathode particle from a charged battery using two instruments—one probing the interior while the other scans the surface—were led by Shaofeng Li, a visiting graduate student at SSRL who will be joining SLAC as a postdoctoral researcher.

On the basis of the study findings, theorists under the guidance of Kejie Zhao, an associate professor at Purdue University, created a computer model that shows how charging would have degraded the particle over a period of 12 minutes and how that damage pattern influences the interactions between the surface and interior.

The picture we are getting is that there are variations everywhere in the particle. For instance, certain areas on the surface degrade more than others, and this affects how the interior responds, which in turn makes the surface degrade in a different manner.

Yijin Liu, Lead Scientist, SLAC

Liu added that the team intends to apply this method to other electrode materials that have been analyzed previously, with specific attention to the effect of charging speed on damage patterns. “You want to be able to charge your electric car in 10 minutes rather than several hours,” he said, “so this is an important direction for follow-up studies.”

SSRL is a DOE Office of Science user facility. Scientists from Stanford University, Virginia Tech, the Advanced Light Source at DOE’s Lawrence Berkeley National Laboratory, and the University of California, Santa Cruz also contributed to the research, which was financially supported by the DOE Office of Science.

Journal Reference:

Li, S., et al. (2020) Mutual modulation between surface chemistry and bulk microstructure within secondary particles of nickel-rich layered oxides. Nature Communications. doi.org/10.1038/s41467-020-18278-y.