AnalySwift, LLC, a provider of efficient high-fidelity modeling software for composites, announced today that Concordia University is participating in its recently launched Academic Partner Program (APP), and it is using its two products, the VABS and SwiftComp simulation software, for researching composite tubes, particularly those used in helicopter landing gear. The research is taking place in the Concordia Centre for Composites (CONCOM), a research group in the Gina Cody School of Engineering and Computer Science at Concordia University.

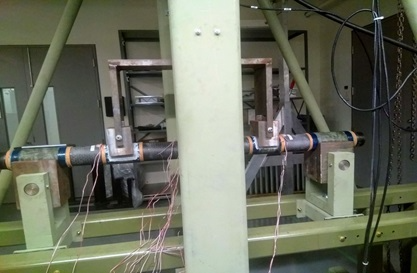

Photograph of composite tube developed at Concordia University and analyzed with SwiftComp (Saeid Khadem Moshir, Concordia University)

Photograph of composite tube developed at Concordia University and analyzed with SwiftComp (Saeid Khadem Moshir, Concordia University)

Lead by Professor Suong Van Hoa, CONCOM has a mission to attain world class excellence in research, training and industrial development activities in composites, with an emphasis on the research and development of low-cost, high-volume polymer matrix composite structures. CONCOM also carries out research on fundamental work in metal matrix and ceramic matrix composites.

“We are working on analysis of composite tubes, including using the variational asymptotic method (VAM),” said Saeid Khadem Moshir, PhD student at Concordia University in the Concordia Centre for Composites. “We are analyzing the bending of thermoplastic composite tubes for the application of landing gear in helicopters. The utilization of a fast and accurate method for analysis of composite tubes made of a large number of layers is necessary. The SwiftComp software is used as an accurate and quick tool for this stress analysis of composite tubes.”

“These tubes are manufactured by an automatic fiber placement machine,” continued Mr. Moshir. “Real life applications for the present research include analyzing stress and bending behavior of cross tubes for landing gear of helicopters.”

The Academic Partner Program (APP) offers participating universities no-cost licenses of engineering software programs VABS and SwiftComp so students, researchers, and faculty can leverage the tools in their academic research. It also affords students an additional avenue to highlight their research as AnalySwift periodically spotlights papers, theses, and articles involving the codes. A robust community of users helps answer questions through the online cdmHUB (composite design & manufacturing HUB) platform.

AnalySwift’s SwiftComp and VABS enable highly efficient, yet accurate modeling of composite structures and materials. SwiftComp, for instance, is a general-purpose multiscale modeling code that enables users to perform efficient and accurate modeling of composites. It provides unified modeling for various types of structures including 1D (beams), 2D (plates/shells), woven, and 3D structures. The VABS program is a general-purpose crosssectional analysis tool for computing beam properties and recovering 3D stresses and strains of slender composite structures. It is a powerful tool for modeling composite helicopter and wind turbine rotor blades, as well as other slender composite structures, such as propellers, landing gear, and high-aspect ratio wings.

“We are excited by the work being done by researchers at Concordia University as part of their academic research on helicopter landing gear, and we are pleased they have selected VABS and SwiftComp as part of their toolset,” said Allan Wood, president & CEO of AnalySwift. “As a versatile simulation tools for composites, they save orders of magnitude in computing time without a loss of accuracy so engineers can consider more design options and arrive at the best solution more quickly.”

“The VABS program is a uniquely powerful tool for modeling composite blades, high aspect ratio wings, and other slender structures, commonly called beams,” said Dr. Wenbin Yu, CTO of AnalySwift. “VABS reduces analysis time from hours to seconds by quickly and easily achieving the accuracy of detailed 3D finite element analysis (FEA) with the efficiency of simple engineering models. With VABS, engineers can calculate the most accurate, complete set of sectional properties such as torsional stiffness, shear stiffness, shear center for composite beams made with arbitrary cross-section and arbitrary material. It can also predict accurate detailed stress distribution for composite beams, which are usually not possible with 3D FEA for realistic composite structures.”

“SwiftComp is a general-purpose, truly multiscale modeling code for composites. It directly and seamlessly links detailed microstructure and structural behavior for composite structures including beams, plates/shells, and 3D structures,” continued Dr. Yu. “It can be used either independently as a tool for virtual testing of composites or as a plugin to power conventional FEA codes with high-fidelity multiscale modeling for composites. It saves hours in computing time and resources with accuracy comparable to modeling all the microstructural details using 3D FEA. SwiftComp quickly calculates the complete set of effective properties needed for use in macroscopic structural analysis. It can also predict accurate local stresses and strains in the microstructure for the purpose of predicting strengths, as well as thermal expansion of composites.”