Belgium-based EconCore are pleased to announce a partnership involving AZL, Audi and others to establish the potential of using composites for battery housings. This eight-month collaborative project will assess the technical challenges, opportunities, and benefits of developing battery casings for electric vehicles using a variety of materials, including thermoplastics.

The project has been established by industry network group, AZL, who specializes in composite-based lightweight technologies and seeks to drive innovation though sharing knowledge.

According to statista.com and marketsandmarkets.com the global battery housing market for electric vehicles is projected to have a growth rate of over 13 percent across the next seven years. Today, battery housings are almost entirely made from aluminium or steel. The industry membership group believe there is huge potential in this area to use lighter composite materials.

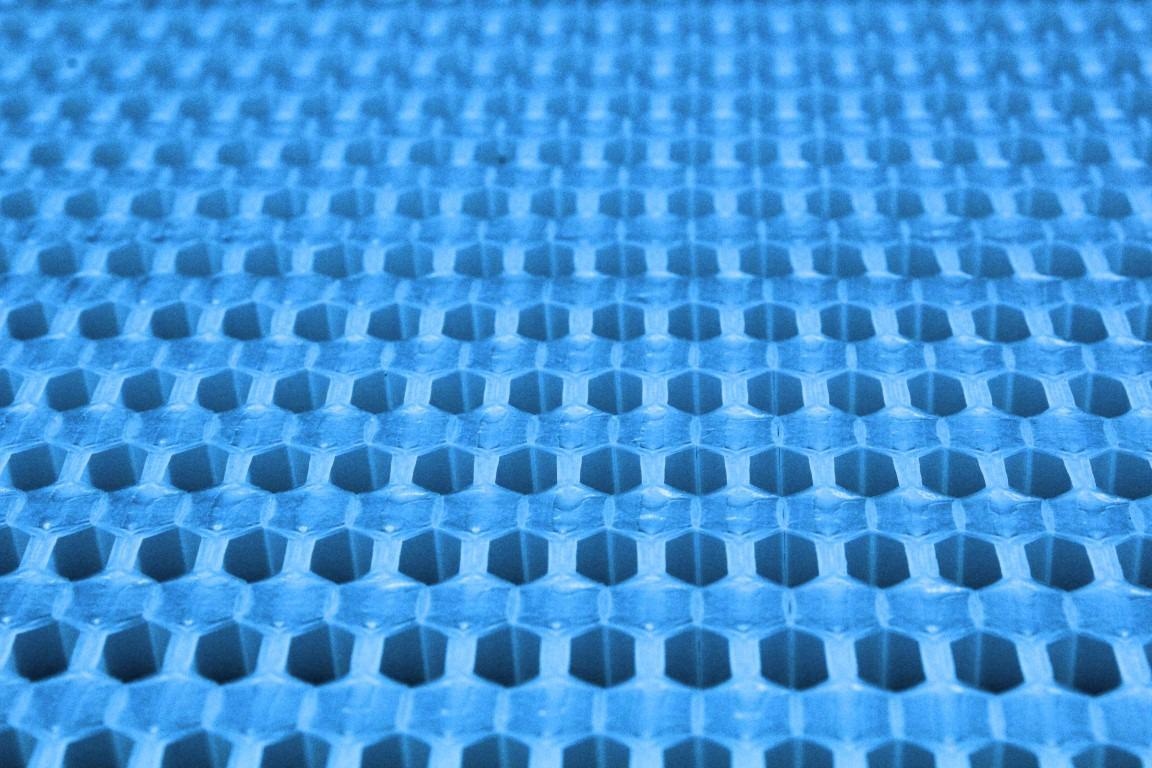

Tomasz Czarnecki, COO of EconCore said: “After successfully establishing the use of the technology in automotive interiors, we feel there is tremendous potential in using composite materials for battery housings and EconCore is now actively working with Audi and other industrial partners, to explore opportunities and to learn how the thermoplastic honeycomb technology can be applied into this area.”

The first phase of this project will be focused on understanding what the potential opportunities and challenges are. For the EconCore team, this means pre-selecting thermoplastic materials, using different composite skin layers and working through different geometrical design variants, to optimize the honeycomb material to obtain desirable characteristics and share findings with project partners.

A primary goal for electric vehicle OEMs is to increase the vehicles operating range, through weight reduction, without compromising on strength and quality.

Czarnecki added: “There’s no doubt there are some interesting opportunities to reduce weight using composite materials. We believe there are even greater potential benefits from using honeycomb sandwich materials, which have incredible strength, while being extremely light, compared to aluminium or steel alternatives.”

EconCore already has experience using honeycomb material in vehicle interiors, which can be compression moulded to produce three dimensional shapes. If the initial phase goes well, the plan is to progress to a prototyping stage.

Czarnecki concluded: “It’s important we don’t get ahead of ourselves. Part of the process is to also understand things like design, material, and the likely production costs. These are also critical factors in addition to the potential lightweighting benefits, that must be assessed. It must make economic sense too. However, we remain optimistic. With our journey through automotive interiors so far, we have seen that that the thermoplastic honeycomb technology delivers opportunities to save costs on both ends, material and conversion.”

For further information about EconCore’s honeycomb technology visit www.econcore.com.