EconCore, world leader in technologies for economic honeycomb sandwich production, has collaborated with partner Flaxco®, to develop and manufacture an innovative new thermoplastic honeycomb sandwich panel.

Image Credit: EconCore N.V.

Flaxco established themselves in the early 1850’s and have 150 years of experience in flax weaving, used in a range of applications including clothing, upholstery and decoration. This has evolved into manufacturing flax fibres for the composites industry, typically found in semi-finished products such as sandwich panels.

In 2020 Flaxco approached EconCore suggesting combination of thermoplastic honeycomb technology with Flaxco’s flax fibre technology. The polypropylene honeycomb material produced by EconCore offers a high-performance-to-weight ratio along with efficient energy absorption.

This is achieved through the materials synonymous honeycomb shaped hollow cells which support sandwich sheets to provide levels of high rigidity with minimal weight. Pioneering the use of flax with honeycomb technology, the partnership sees Flaxco’s flax fabric composite skins combined with EconCore polypropylene core to produce sandwich panels.

In order to generate high level of stiffness, sandwich cores require surface layers, like the neatly woven layers that Flaxco have the means to create. Once created the panels can be thermoformed thanks to their thermoplastic properties. This is typically done by means of short cycle compression moulding.

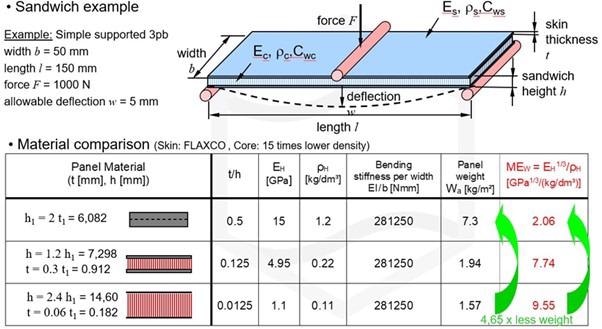

Achieving a product with well-balanced characteristics, required pre-pregs of 0.5-1 mm thickness to be used. By optimising flax technology with the polypropylene honeycomb core Flaxco is able to achieve much higher levels of rigidity. The table below describes the bending performance of a sandwich panel with flax composite skins.

Image Credit: EconCore N.V.

Flax fibres are a 100% natural fibre that produce lower CO2 levels than competitor materials including glass and carbon fibres, an increasingly important element within the automotive industry. Furthermore, research and testing are already underway for the material to find its place within the sports industry.

With high levels of cost efficiency compared to more conventional materials, the new Flaxco composite is expected to be the material of choice in a number of applications, especially those requiring dimensional stability. The new material aims to not only be used in new markets and applications but also replace non-sustainable materials already in use.

Dr. Jochen Pflug, EconCore CEO added: “For new product developments sustainable materials have become a key requirement. Within the automotive industry in particular, suppliers seek sustainable materials which lower their CO2 footprint.”

Dr. Pflug continued: “Flaxco’s natural flax fibre polypropylene composites are an ideal combination with our polypropylene honeycomb cores to achieve a sustainable material that retains high levels of performance. The production costs of thick monolithic laminates are high because many layers need to be combined, our honeycombs increase the stiffness and strength but require only a minimal amount of material in two thin surface layers.”

One factor that has greatly benefitted the partnership between Flaxco and EconCore is the locations of their facilities. With both EconCore and Flaxco being based in Belgium, allowing for a local supply chain. Throughout both the design and manufacturing stages the advantages of this proved its advantages with regular stable deliveries and less transport being required, essential when one crisis after the other affects the transportation chains, from the Coronavirus pandemic to the recent raw material shortages.

Ludwig Ryckebosch, Innovation and Business Development Manager at Flaxco said: “It was a match made in heaven. EconCore’s polypropylene honeycomb has been incredibly easy to work with. Its lightweight properties meant that it was the perfect choice to combine with our technology to develop flax fibre composite material.”

The flax composite material is expected to have commercial applications across many industries, especially automotive interiors and computer casings. With sustainability being a key focus for companies across the globe, this all-new flax composite’s ability to be recycled without compromising on performance will play its role in reducing carbon emissions.