Composites fibre and textiles splicing experts, Airbond, has increased the limits of normal splicers by a factor of 10 while at the same time enabling huge waste reduction. It is doubling its product range with the launch of 12 new splicers for the composites and textiles industries, including models focused on waste recovery. There are now 24 different splicers for a wide range of applications in these industries, covering all fibres including polypropylene, nylon and glass.

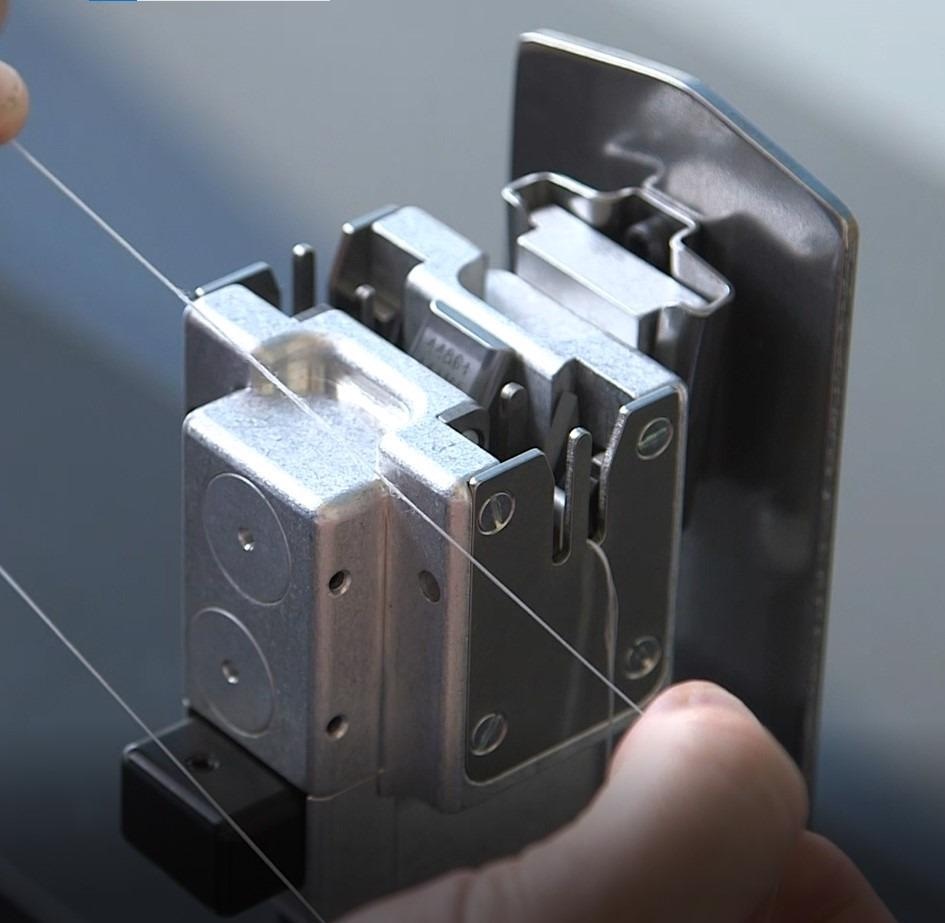

This new range, which is protected by several patents, is revolutionising the use of fibres, enabling splicing of much higher concentrations and more difficult material. Some of the key, enhanced capabilities are:

- Splicing super-large yarns – up to 16,000 tex, compared to 1,200 by most normal machines. It can come with a flow control system which supplies variable-pressure air to the blast chamber, while keeping the main factory line pressure unchanged. It can be used to deliver distinct, innovative techniques for joining brittle yarns such as glass and carbon and joining inherently strong aramids.

- The fixed-position splicer for efficient waste yarn recovery. This can be used for “bit-winding” – where full-weight bobbins are created by repeatedly winding “shorts”, splicing them together several times until a full weight is reached. It is bolted to a simple bit-winding machine and is designed for frequently repeated splicing over long periods.

- The all-new wrapping splicer. This can be applied to monofilaments, fibrillated tapes (which are used in 4G football pitches), braided yarn, very heavily-sized or coated yarn and very high-twist yarn, which are traditionally problematic materials. Two yarn ends are overlapped, and a fine auxiliary yarn is tightly wrapped around them and bound to produce a joint of high strength. The jointing method has a patent pending.

Lighter, simpler and much more tolerant of rough treatment, the new line up can massively save companies time and reduce wastage and are earning their payback in days. Most of the new products complement the existing range by enhancing their ergonomics or improving the performance specification with products that splice above the 1,200 tex, to 2,400 and 4,800 tex.

The main structures (bodies) of all Airbond splicers are now 3D printed to a very high standard, rather than manufactured from milled aluminium. These revised products also now come with a much longer, five-year guarantee1 and are tougher than anything else on the market. They are also lighter and more reliable.

The new splicers will make a huge impact on the textiles process of “bit-winding”, delivering a better class of splice. It will also enable partially used bobbins in the composites industry to be combined, reducing waste significantly making bit-winding feasible. A bunch of short-weight bobbins are brought together, and are re-wound, one after another, onto a fresh bobbin, with joints made between each. The result is a full-weight bobbing with perhaps 20 splices buried within it. So operators are making a splice, maybe every 30 seconds, for eight hour shifts.

Graham Waters, managing director of Airbond said:

“This is an exciting period for the company. We have put years of developing and clever thinking into these new products to really improve the range and introduce new capabilities. We believed there was a demand to satisfy the needs of waste yarn recovery, hence we created the new range.

“We carried out beta testing with similar products, designed for textile markets, and the response has been overwhelmingly positive, with existing customers much preferring the new design.”

Significant cost reductions can be made by companies who work in fibre manipulation through saved time and the elimination of wastage. Splicers reduce waste by producing smooth joints between composite threads.

It has been historically challenging to make spliced joints in materials such as carbon fibre. After many years of research, Airbond successfully developed a robust method suitable for most composite applications, to splice composite materials.

Two-time Queens Award winners for innovation, Airbond, have invested in research and development consistently over many years, constantly refining their products. The new range is available now and offers solutions for ultra-fine yarns through to very large tows, of carbon, glass, or other synthetics.

To find out more, visit: http://www.airbondsplicer.com/.