Poorly soluble, viscous, and often highly contaminated– determining the water content in lubricants, hydraulic oils, and other petrochemical samples can be a messy business. Addressing these challenges, ASTM has revised standard method D6304. The revised standard now includes the Karl Fischer oven technique. A free white paper describes how users can conveniently and accurately determine water content in up to 35 samples fully automatically by coulometric Karl Fischer titration.

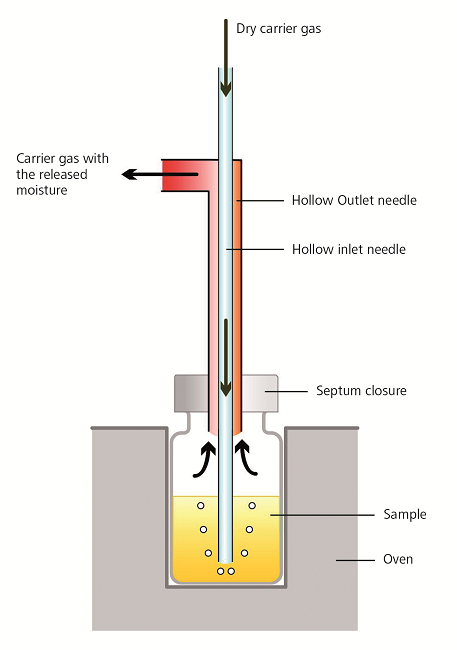

Using the Karl Fischer oven technique, the oil matrix does not come into contact with the titration cell at all. Instead, the samples are introduced in single-use vials, which are put on the rack of an oven sample processor. Heating vial by vial, the water contained in the samples is evaporated. A constant stream of inert carrier gas is used to bring the water fraction into the titration cell, where it is determined colorimetrically. The sample matrix stays in the vials, which are disposed of after the titration. The benefits of this method are considerable:

- No contamination of the KF titration cell

- No matrix interferences

- Less solvents needed

- Better reproducibility of results

- Automation possible for serial, completely unattended determination of multiple samples

Karl Fischer oven method: no contamination of the titration cell and no matrix interferences

QC laboratories from the petrochemical sector and contract laboratories facing high sample loads can use the Karl Fischer oven technique to increase the efficiency of their routine analysis in compliance with the official standard. Karl Fischer oven method: no contamination of the titration cell and no matrix interferences