Mar 23 2021

A new structural battery created by scientists from the Chalmers University of Technology can perform 10 times better than all the earlier prototypes.

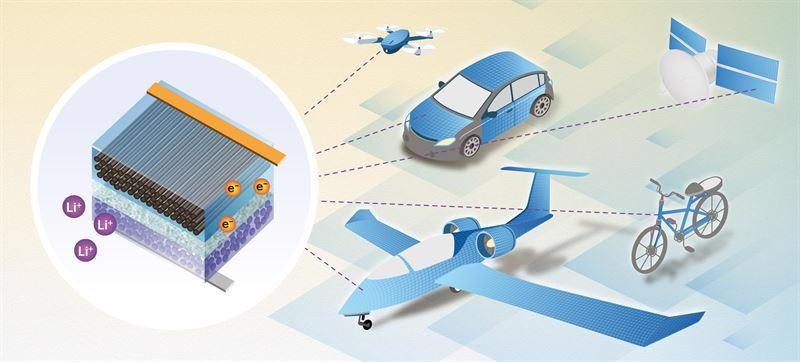

Structural battery composites cannot store as much energy as lithium-ion batteries, but have several characteristics that make them highly attractive for use in vehicles and other applications. When the battery becomes part of the load-bearing structure, the mass of the battery essentially “disappears.” Image Credit: Yen Strandqvist/Chalmers University of Technology.

Structural battery composites cannot store as much energy as lithium-ion batteries, but have several characteristics that make them highly attractive for use in vehicles and other applications. When the battery becomes part of the load-bearing structure, the mass of the battery essentially “disappears.” Image Credit: Yen Strandqvist/Chalmers University of Technology.

The structural battery contains carbon fiber that acts as a conductor, electrode, and load-bearing material at the same time. This latest advancement may lead to essentially ‘‘massless” storage of energy in vehicles and other similar technologies.

In present-day electric cars, the batteries represent a major part of the weight of vehicles and yet do not fulfill any load-bearing function. On the other hand, a structural battery functions both as part of the structure and as a power source—for instance, in a car body.

This technology is known as “massless” energy storage because the weight of the battery essentially disappears when it turns out to be a part of the load-bearing structure. According to estimates, the weight of an electric vehicle could be significantly reduced by this kind of multifunctional battery.

At the Chalmers University of Technology, the development of structural batteries has proceeded through several years of studies, including the earlier findings that involved specific kinds of carbon fiber.

Apart from being strong and stiff, the structural batteries also have an excellent potential to chemically store electrical energy. The study was named as one of 2018’s 10 biggest scientific breakthroughs by Physics World.

Scientists had initially attempted to develop a structural battery as early as 2007 but to date, it has been difficult to produce batteries that have both excellent mechanical and electrical properties.

Now, investigators from the Chalmers University of Technology, in association with KTH Royal Institute of Technology based in Stockholm, have demonstrated a novel structural battery that has taken this development one step forward. The new battery has properties that relatively surpass anything yet seen, in terms of strength, stiffness, and electrical energy storage.

The multifunctional performance of this battery is 10 times more than the earlier versions of structural batteries. In addition, the new battery has an energy density of 24 Wh/kg, which means about 20% more capacity when compared to similar currently available lithium-ion batteries.

But since it is possible to reduce the weight of the vehicle, less energy will be needed to drive an electric car, for instance, and lower energy density also leads to more improved safety. With a stiffness of 25 GPa, the new structural battery can truly contend with several other frequently used construction materials.

Previous attempts to make structural batteries have resulted in cells with either good mechanical properties, or good electrical properties. But here, using carbon fibre, we have succeeded in designing a structural battery with both competitive energy storage capacity and rigidity.

Leif Asp, Project Leader and Professor, Chalmers University of Technology

Super Light Electric Bikes and Consumer Electronics Could Soon be a Reality

The new structural battery features a positive electrode composed of a lithium iron phosphate-coated aluminum foil and a negative electrode composed of carbon fiber. These electrodes are separated in an electrolyte matrix by a fiberglass fabric.

But despite their success in producing a structural battery, whose performance is 10 times better than all the previous versions, the team did not select the materials to set a new record but instead, they preferred to study and figure out the impacts of separator thickness and material architecture.

Now, a new study funded by the Swedish National Space Agency is ongoing in which the performance of the structural battery will be further improved. In the positive electrode, the aluminum foil will be substituted with carbon fiber as a load-bearing material, offering both increased energy density and stiffness.

An ultra-thin variant will be used in the place of the fiberglass separator and this prototype will offer a relatively higher effect and also faster-charging cycles. It is expected that the new study will be concluded in less than two years.

Leif Asp, who is also heading the new study believes that a battery like this may reach a stiffness of 75 GPa and an energy density of 75 Wh/kg. This would make the battery almost as powerful as aluminum but with a relatively lower weight.

The next generation structural battery has fantastic potential. If you look at consumer technology, it could be quite possible within a few years to manufacture smartphones, laptops or electric bicycles that weigh half as much as today and are much more compact.

Leif Asp, Project Leader and Professor, Chalmers University of Technology

In the longer term, it is entirely conceivable that electric planes, electric cars, and satellites will be developed with and driven by structural batteries.

We are really only limited by our imaginations here. We have received a lot of attention from many different types of companies in connection with the publication of our scientific articles in the field. There is understandably a great amount of interest in these lightweight, multifunctional materials.

Leif Asp, Project Leader and Professor, Chalmers University of Technology

Structural battery with record performance

Video Credit: Chalmers University of Technology.

Journal Reference:

Asp, L. E., et al. (2021) A Structural Battery and its Multifunctional Performance. Advanced Energy & Sustainability Research. doi.org/10.1002/aesr.202000093.