Toronto, ON — August 2020 — In the time of COVID-19, businesses are finding new and innovative ways to apply modern technology to continue providing products and services to their customers. Businesses in the manufacturing sector have been particularly affected by social distancing and travel restrictions, since obtaining accurate measurements and specifications is critical to many fabrication methods.

Image Credit: Firwin

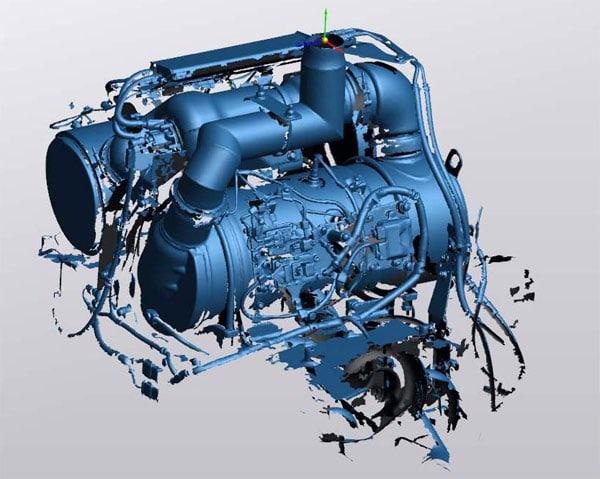

Fortunately, Firwin has experience using the latest remote scanning methods to obtain accurate measurements for the custom insulation solutions it manufactures. Our focus on process innovation and new technology has made us uniquely prepared for remote operations during the COVID-19 crisis.

Image Credit: Firwin

Remote Scanning Services

Our remote scanning service allows us to determine the dimensions of your equipment to ensure precise insulation coverage for your exhaust, motor, generator, or other system. While we have extensive experience using the latest CAD and 3D modeling software in conjunction with traditional photos and sketches, we also have expertise in the use of remote scanning for inaccessible and uniquely shaped components.

Before the advent of remote scanning technology, it was not uncommon for engineers to physically examine equipment and take measurements. With increasing travel restrictions and social distancing requirements, this is simply not feasible. Even before the pandemic arrived, Firwin was working to reduce costs by employing remote 3D scanning instead of flying engineers across the country. The method proved to be highly effective in numerous designs, and our customers have been pleased to receive highly precise custom-designed blankets at a fraction of the cost.

Benefits of Remote Scanning

As COVID-19 continues to change the face of manufacturing, remote scanning is not only relevant, but necessary for successful manufacturing operations. It offers numerous benefits, particularly during the current health crisis.

Improved Safety

Remote scanning allows engineers and customers alike to avoid potentially unsafe conditions by eliminating the need for on-site visits. Modern remote scanning technology provides highly accurate measurements quickly and efficiently.

Cost Efficient

Even before the COVID-19 pandemic, Firwin’s experts saw the benefits of remote scanning technology, especially for customers in distant and remote locations. Rather than paying for the travel and work hours spent manually inspecting and measuring the equipment, our engineers can obtain the information they need via remote scanning, saving hundreds, and sometimes thousands, of dollars in billed hours and expenses.

Comparable Accuracy

With Firwin’s remote scanning technology, you can rely upon the results. We employ the latest scanning technology and have completed successful projects with the same degree of accuracy as an on-site visit.