May 31 2021

Electroceramics, including capacitors, are crucial parts of electronic devices. But any disruption to the crystalline structure of these electroceramics can alter their specific properties.

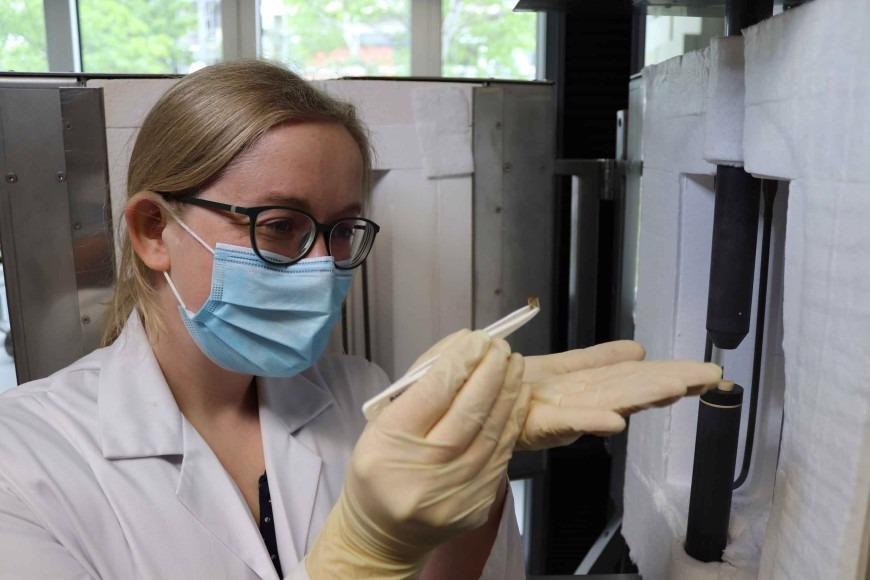

Marion Höfling examines a single crystal after successful mechanical deformation. Image Credit: Technische Universitat Darmstadt.

Therefore, for example, chemical techniques can be used to substitute separate atoms in the crystal lattice with others. It is possible to create a stable shape by substituting an entire series of atoms instead of only a single one.

For the first time, an international research team under the guidance of the Technische Universitat Darmstadt (TU Darmstadt) has successfully introduced a dislocation into a ferroelectric ceramic by mechanically imprinting the material atoms—a process that so far has only ever been applied to metals. The latest results have been published in the leading journal Science.

The global market for electroceramics lies in the region of 25 billion euros per annum. Most often, these tiny components are not even perceived in day-to-day life. A smartphone alone comprises 600 capacitors, of which three trillion—that is, 3000 billion—are produced each year.

The way several electroceramics operate does not depend on the flow of current via the material but is based on slight dislocations of charge, known as polarization, across fractions of an atomic diameter.

Globally, around a quarter of the electroceramics manufactured connect this polarization to an extension of the material. This material can be consequently altered to the precision of an atomic diameter and only then it would be possible to structure the ever-smaller microrobots and computer components.

Replacing Atomic Series in the Atom

To improve the characteristics of the electroceramics, chemical interventions can be used to substitute individual atoms in the routinely shaped crystal lattice with others (endowing)—somewhat like sitting a solo Borussia Dortmund fan in a black-and-yellow jersey in a cinema packed with FC Bayern Munich fans in red tops.

But where there are unique needs, like a higher electric voltage or temperature, the endowed atom would lose its position (the fan would be shoved around), much to the disadvantage of the ceramic function.

Within a ceramic crystal lattice, the installation of separate atoms is not sufficiently stable for complex needs; however, the installation of whole atomic series (displacement) is quite powerful. In the case of the football analogy, this would correlate to having a row of Borussia fans among the Bayern fans.

Material scientists from three working teams of the TU Darmstadt are collaborating with other research teams from Switzerland, the United States, and the Netherlands to investigate these displacements.

New Atoms, New Properties

Chemical methods are no longer sufficient for planned displacements.

Jürgen Rödel, Professor and Head of Research Group of Non-Metallic Inorganic Materials, TU Darmstadt

Instead, the investigators successfully achieved the displacement mechanically. The team employed a process where the ceramics are mechanically deformed under regulated temperature and pressure conditions and, therefore, the displacement could be imprinted in the ceramic. This approach is trivial in the case of metals, but to date, it was chiefly considered to be impossible with ceramics due to their extreme hardness.

Besides this, the ceramic surface is highly brittle and can break easily. Hence, to address these barriers, the researchers performed a mechanical imprint at 1150 °C in an individual crystal of the formerly estimated optimized orientation.

This technique now enables a well-ordered field of the recently occupied rows of atoms. Such series regulate the local polarization—that is, the load dislocation—in the material. Since the imprinted series evidently restricts polarization, it retains its structure even under extremely high operating conditions.

During the operation of electroceramics, the areas of the material that are currently delimited by the series (displacements) assume specific charge shifts; and continuing with the football example, it is as if the Bayern fans were to lean to the side or forward in sections. Since the areas of the material do not alter even under high conditions, energy is not changed by internal friction and the behavior of the material continues to remain stable.

Now, such materials help ensure reliable properties even at increased temperatures and with increased use of energy. The team is also dealing with the cost reduction required to offer the displacements through many options of mechanical imprinting.

Journal Reference:

Höfling, M., et al. (2021) Control of polarization in bulk ferroelectrics by mechanical dislocation imprint. Science. doi.org/10.1126/science.abe3810.