Analyzing structures at the nanoscale is crucial for the accurate characterization of their properties. Additionally, reliable high-resolution non-destructive nanoscale imaging techniques are necessary for the materials science and engineering fields. A new paper published to arXivLabs demonstrates a novel nanotomography technique that can reliably and non-destructively image nanoscale structures at resolutions of 150nm.

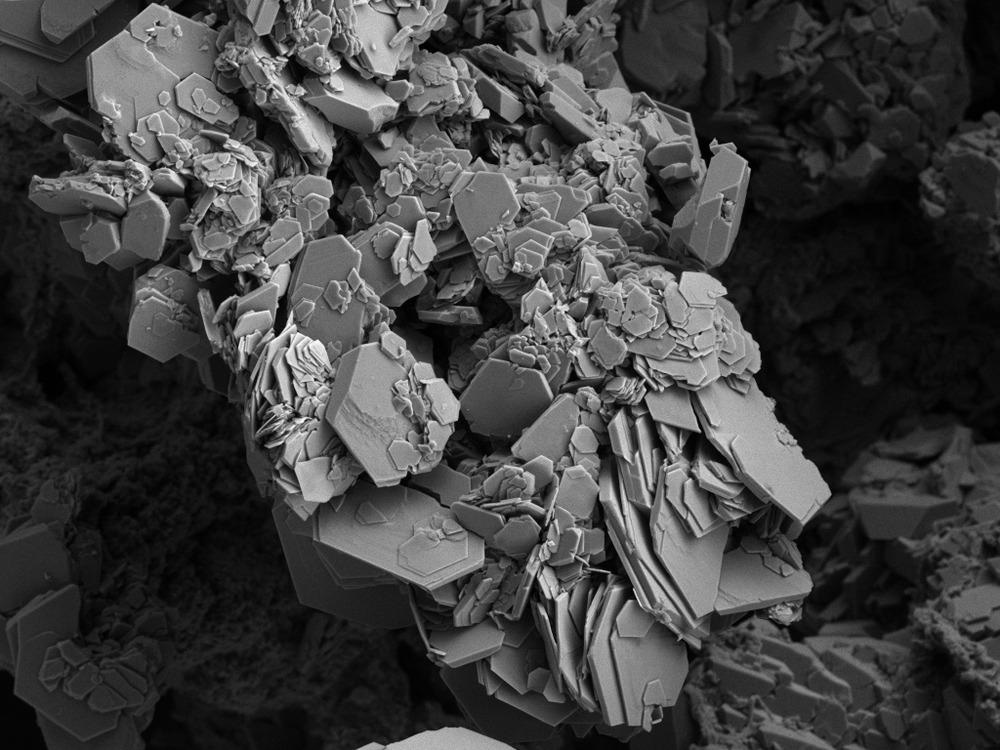

Study: A Novel Nano Tomography Setup for Material Science and Engineering Applications. Image Credit: Ravenash/Shutterstock.com

What is Nanotomography?

Nanotomography is an analytical technique similar to tomography and microtomography. The technique uses X-Rays to create cross-sections of a three-dimensional object without destroying the sample. The cross-sections created via the technique can then be used to recreate a virtual model of the object.

Nanotomography has already found application in research, such as analyzing neuron deformation in the brains of patients with schizophrenia and analyzing comet samples gathered by the Stardust mission.

Limitations of Current Technology

High-resolution X-Ray microscopy research is mainly carried out using synchrotrons. Optics-based full-field microscopy techniques have been developed in recent years and are seeing implementation in laboratories worldwide. Whilst widely available models can resolve images less than 100nm in scale, they are restricted to low energies due to technical challenges.

This limits their potential applications in material research.

Downsizing the X-ray source is an alternative approach for nano computed tomography. Thin layered structures of nanoscale needle tips can be used for the electron source. This approach requires the use of modified scanning electron microscopes (SEMs.)

By doing so, resolutions of less than 100nm can be achieved, and the sample size is not restricted to the optical depth of field. However, a major drawback is its destructive nature: samples must be held in a vacuum.

Developing a system that utilizes a high-powered X-ray source without the need for a vacuum that can image structures at the nanoscale is needed.

Developing a Reliable, Versatile, and Non-Destructive Nano CT System

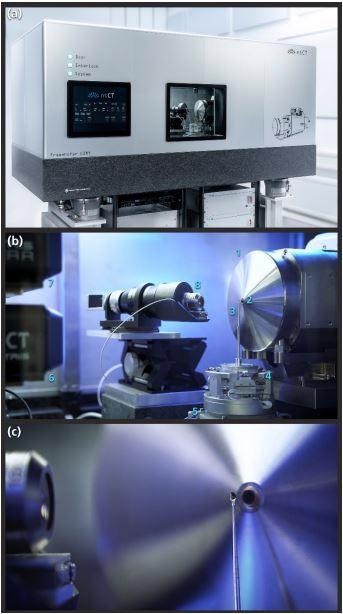

Research published online in October 2021 to arXivLabs has demonstrated the development of a versatile nano CT system, which the team behind it have called “ntCT.” The system can reliably image structures at a resolution of 150nm to create high-quality 3D virtual models of materials. The method can be applied to the examination of objects both larger and with higher absorption than conventional methods are able to analyze.

Compact and integrated design of the laboratory nano CT setup. (a) Exterior view of the system with a temperature-controlled lead booth and air-bearing granite for vibration damping. (b) Inside view into the device with 1. nanofocus X-ray source, 2. exit window and at the same time tungsten transmission target on a diamond substrate, 3. sample mounted on a needle-shaped holder, 4. 6-DOF hexapod made of piezo linear axes for fine adjustment of the sample on the rotation axis, 5. air-bearing rotary stage (and in the picture not visible below three further linear axes for positioning of the sample holder), 6. DECTRIS EIGER2 R CdTe detector on 3 linear axes, 7. optional DECTRIS detector with SI sensor, 8. optical microscope to support the sample adjustment. (c) Detailed view of the sample position in front of the exit window of the X-ray source with the mounted specimen. Image Credit: Müller, D et al., arXivLabs

Images were rendered in both two and three dimensions, using a Siemens star test pattern and Fourier Shell Correlation respectively to validate resolution. The results were compared with previously known results via visual confirmation.

The samples used semiconductors, filler particles of silicone polymer composites, and lithium-ion battery electrodes. These three samples were chosen for their relevance to materials research. Reconstruction of the data was made with a system developed in-house by the research team.

Data were corrected to account for deviations such as sample drift and irregularities in the sensitivity of detector pixels, both of which are inevitable in nano CT.

Semiconductor Samples Imaged at Nanoscale Resolution

The technique was used to reconstruct a scan of a commercially available semiconductor memory chip from SanDisk. The 3D sample volume of the semiconductor sample was imaged in stunning detail. In particular, the tungsten contacts which connect the storage layers to the electronics could clearly be seen.

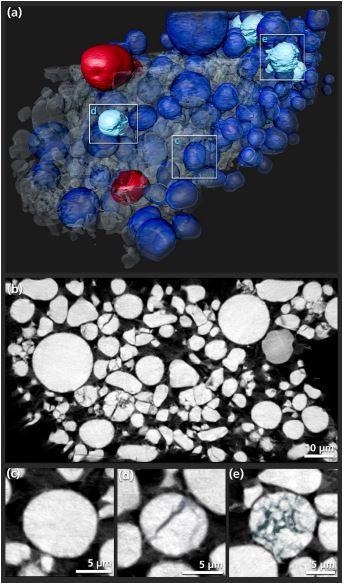

Reconstruction of the high-resolution nano CT measurement of the electrode of a commercial lithium pouch-cell with 105 nm sampling. (a) 3D rendering of the sample. Typical spherical particles in the electrode are shown in blue, spherical particles with already strong fragmentation inside are turquoise, the two red particles have a much weaker absorption and seem to have a different material composition. (b) unrendered sectional image from the reconstructed volume to get an overview of the aging state. (c) – (e) enlarged sections of individual spherical particles. (c) in good condition as the majority of the sample. (d) medium fissure as the first consequence of mechanical or chemomechanical stress. (e) already heavily broken particle. Image Credit: Müller, D et al., arXivLabs.

Various images determining and specifying structure types and sizes were produced. The technique found no obvious defects in the sample, as would be expected from a commercially available semiconductor chip.

Battery Research with Nano CT

NtCT was used to reconstruct an image of the electrode in a lithium-ion battery. Three-dimensional rendering showed the distribution and shape of the electrode’s active phases. False colors were applied to components in different states.

Images were produced of the particles in the electrode at varying degrees of aging, untypical material composition, and showing fissures because of stress. Images like this are important to battery research as they provide information on aging behavior and help to inform better long-life battery design.

This research demonstrated that the nanotomography technique described could detect micro-cracks in a three-dimensional volume and provide analysis of distribution and location.

Using NtCT to Analyze Functional Materials.

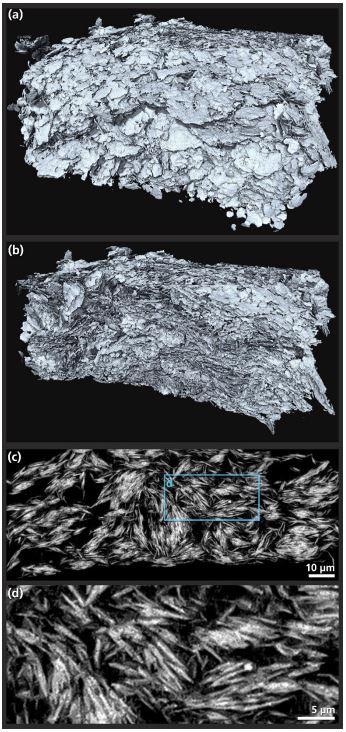

Images of segmented, flaked metallic filler particles of silicon polymer composite were produced in the study. The development of this class of composite material depends on a high-resolution analysis of these flaked metallic particles, in particular their alignment, distribution, and directional effects.

Reconstruction of the nano CT scan of the functional material composite. (a) 3D rendering of the whole reconstructed sample consisting of a flat cuboid with an edge length of about 100 µm. The rendering focuses on the metallic filler, whose orientation is essential for the function of the material. (b) sliced sample from the above rendering in which the self-organized alignment of the filler can be seen. (c) sectional image from the reconstruction, demonstrating that the particles have aggregated and locally compressed during the cyclic loading. (d) enlarged detail of the sectional image. Image Credit: Müller, D et al., arXivLabs.

The information gathered by rendered 3D volume imagery produced by NtCT demonstrated its potential to aid the development of important, functional materials.

The Future

NtCT has the potential to become a key technology in materials research and engineering. Being able to image structures and functional materials at the nanoscale will help to inform the future development of a swath of new materials and products for a multitude of important industries.

Further Reading

Müller, D et al. (2021) A Novel Nano Tomography Setup for Material Science and Engineering Applications (.Pdf) arxiv.org. Available at:

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.