There has been increasing interest in the current and potential applications of mixed ionic-electronic conducting (MIEC) membranes over the past thirty years. A new review in the journal Advanced Functional Materials considers the opportunities and challenges of these applications.

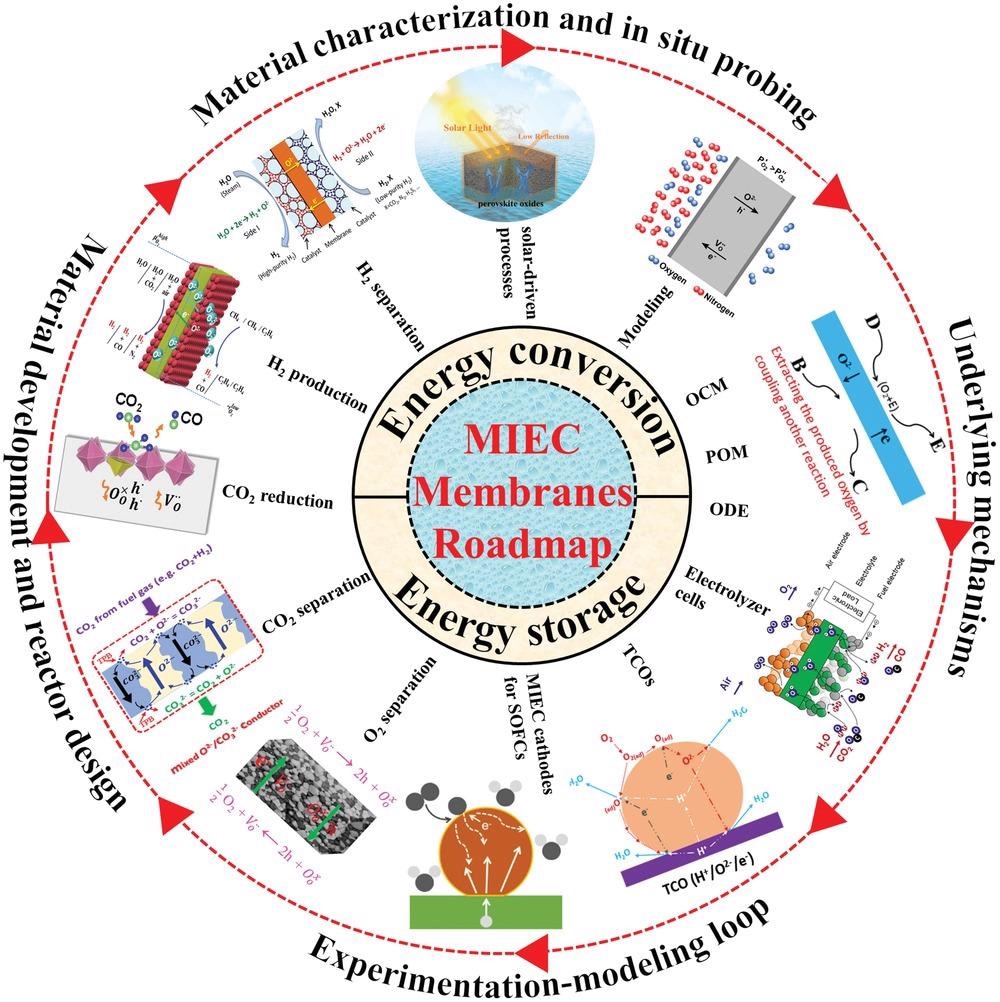

Study: Roadmap on Sustainable Mixed Ionic-Electronic Conducting Membranes. The figure depicts the research topics of MIEC membranes that are covered in the roadmap. Image Credit: Guoxing Chen et al., Advanced Functional Materials, Wiley.

MIECs’ potential for use in environmental and energy applications has seen an increase in popularity and applicability, with emerging use cases including a range of CO2 reduction and separation and H2 and O2 production and separation applications.

These have also seen use in membrane reactors used in chemical production, in the development of cathodes for solid oxide fuel cells, as electrolyzer cells for power-to-X technologies, and in solar-driven evaporation and energy-saving regeneration technologies.

MIEC membranes work by simultaneously conducting oxygen ions and electronic charge carriers, facilitating advanced chemical and fuel processing, as well as energy storage and conversion applications.

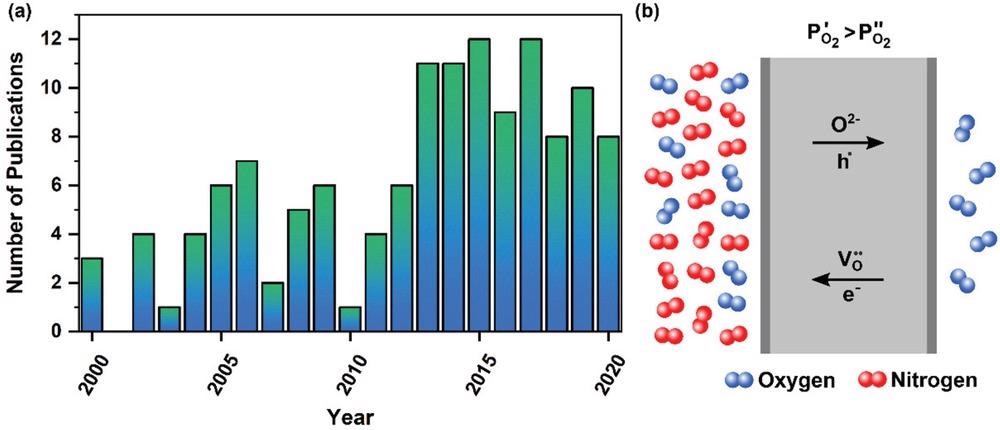

Increasing demands for oxygen production across an array of sectors have seen MIEC membranes garner increasing attention in industrial and academic spaces due to their theoretical potential to simply and cost-effectively separate oxygen with 100% permeation selectivity.

In order to fully exploit this potential, advanced experimental and modeling work is ongoing to enable the design and development of cost-effective MIEC membranes that offer the right combination of chemical stability and O2 permeation flux.

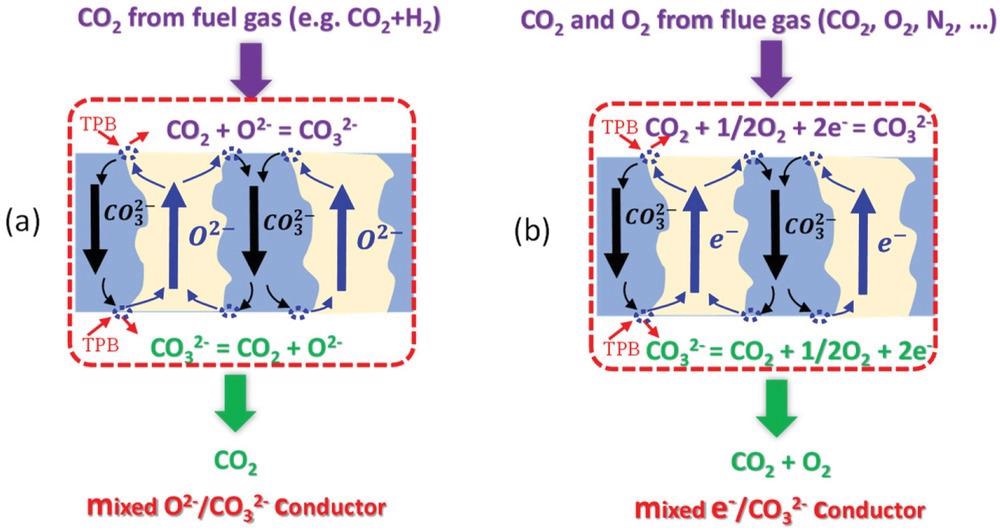

Similar demands for carbon dioxide transport and conversion exist across a number of areas, with MIECs offering excellent potential for use in CO2 transport membranes (CTMs) based on high-temperature mixed conducting chemistry.

These membranes may offer the ability to efficiently and selectively capture and convert CO2 from any CO2-containing process into valuable products, all within a single high-temperature reactor.

Despite being a useful gas in many applications, CO2 remains a major greenhouse gas, with countries around the world striving to reduce their CO2 output to reach a net-zero carbon economy. As a result, there is also a pressing need to remove excess CO2 from the atmosphere.

Extensive research has been undertaken to explore the applicability of MIEC membrane-supported CO2 reduction technology, revealing the excellent potential for these membranes to be integrated with renewable thermal energy sources for carbon dioxide utilization.

a) Trend of oxygen permeation flux modeling-related publications between 2000 and 2020. b) Conceptual figure of oxygen transport through dense MIEC membrane. Image Credit: Guoxing Chen et al., Advanced Functional Materials, Wiley.

Another notable use of MIEC membrane technology lies in solar-driven evaporation, which sees photothermal technology used to harvest solar energy into thermal energy as a means of improving localized surface temperature and generating vapor at temperatures lower than liquid boiling temperature.

While optimal MIEC membrane materials are yet to be developed for this application, solar-driven processes employing MIEC membranes offer an exciting potential means of converting solar energy to a number of energy forms, potentially helping to alleviate a range of pressing energy and environmental problems.

As this necessity for a global energy transition continues to grow, the application of MIECs in a range of application spaces could help drive the societal and scientific changes required to help facilitate this transition.

In light of these factors, a comprehensive roadmap was recently produced by a team of international specialists in their fields, aiming to provide a multidisciplinary perspective and insight into current state-of-the-art MIEC technologies, ongoing challenges, potential solutions, and future opportunities across a series of 12 broad research and application fields. The research is published in the journal Advanced Functional Materials.

The interdisciplinary nature of this field has further increased the need to ensure strong application foundations based on a comprehensive understanding of the underlying physical and chemical processes to MIECs’ functionality.

This understanding and strong foundation of knowledge is also key to enabling and empowering the next generation of researchers in this vital area.

Working principles of a) MOC-based; b) MEC-based CTMs. Image Credit: Guoxing Chen et al., Advanced Functional Materials, Wiley.

The roadmap aims to highlight and explore the connection between membrane- and catalyst-assisted gas conversion and separation technologies, and the necessarily rapid development of sustainable energy sources and green energy solutions.

The researchers outline and examine a range of key topics across several recently emerging research fields, all of which involve the current or potential use of MIEC membranes, with specific attention paid to progress in terms of the commercialization of MIEC membrane technology.

The roadmap offers excellent potential as an entry point for scientists exploring the MIEC membranes field for the first time, and as a resource for industry professionals looking to better understand the potential of MIEC membranes.

The authors of the roadmap hope that it will help it will be informative and useful in supporting academic and industry-oriented research towards the viability, commercialization, and more widespread adoption of MIEC membranes for a range of different applications.

Reference:

Chen, G., Feldhoff, A., Weidenkaff, A., Li, C., Liu, S., Zhu, X., Sunarso, J., Huang, K., Wu, X., Ghoniem, A. F., Yang, W., Xue, J., Wang, H., Shao, Z., Duffy, J. H., Brinkman, K. S., Tan, X., Zhang, Y., Jiang, H., . . . Kriegel, R. (2021). Roadmap on Sustainable Mixed Ionic‐Electronic Conducting Membranes. Advanced Functional Materials, 2105702. https://onlinelibrary.wiley.com/doi/full/10.1002/adfm.202105702

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.