Nanotechnology is a rapidly growing discipline of science concerned with the creation of nanoparticles made up of various materials. Research in the journal Materials considers their use in concrete as an essential construction material.

Study: Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact. Image Credit: Bannafarsai_Stock / Shutterstock

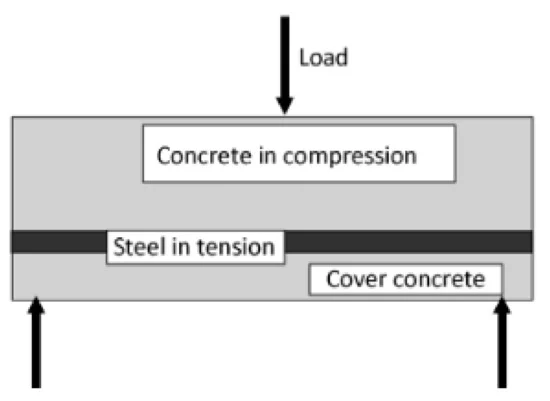

Figure 1. Schematic illustration of a simple reinforced concrete beam.

Nanotechnology is generally defined as the scientific study of manipulating matter on a nanoscopic scale that enables the development of novel methods and technologies with sizes ranging from 1 to 100 nanometers, with various applications from aerodynamics to healthcare.

This innovation has a significant economic potential for industries and is generally thought to be enticing. At the nanoscale level, materials behave differently, and nanomaterials may be used to achieve outstanding outcomes in various sectors.

Nanotechnology is now a major study subject in many nations, owing to its tremendous potential and economic significance.

Nanotechnology has recently been discovered to have a wide range of uses in the building industry. Coating, concrete, glass, steel, bricks, and insulating all utilize nanomaterials. The numerous developing applications of nanoparticles in concrete and their associated health concerns and environmental implications are considered in Materials.

Semidry concrete for a road foundation. Image Credit: Saleem, H, Materials

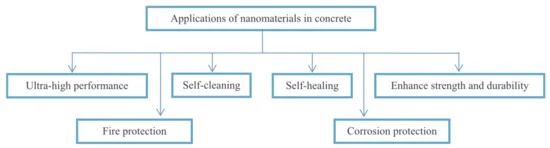

Nanoparticles such as nano-TiO2, nanosilica, carbon nanotubes (CNTs), polycarboxylates, ferric oxides, and nanocellulose can improve the thermal and mechanical qualities of buildings, hence increasing their durability. This might result in reduced energy use and overall costs in the concrete industry.

Concrete is an important part of building. Sand, gravel, or crushed stone are used as aggregates, and the paste is made up of water and cement. Concrete is becoming more popular, thanks to high-performance concrete developed for specific construction and building needs.

Cement, a concrete component, makes up 10 to 15 percent of the overall amount of the concrete mix proportion. The cement and water will solidify and join the mixtures to form a rock-like mass through a hydration procedure. In the hydration and hydrolysis processes, cement dissolves in the water.

Reinforced concretes comprise composite materials formed up of a variety of component elements that have complementary qualities. Steel and concrete are the most common component elements in reinforced concretes.

Current concrete constructions necessitate structural components with greater mechanical characteristics and a longer lifespan. This may be accomplished by incorporating nanostructured elements into concrete to increase its mechanical qualities.

Through the use of nanotechnology in concrete buildings, there has been shown the potential to boost longevity, tensile stability, and mechanical strength, lowering maintenance costs and eliminating the need for immediate replacement. In the foreseeable future, a greater understanding of nanomaterial properties will help identify a better approach to creating innovative materials, improving livelihoods.

Many investigations have confirmed the use of numerous nanoparticles in concrete, which has been thoroughly evaluated in several study works as a nano-enabled material. The porosity of cement is reduced by nanomaterials, resulting in denser and better interfacial bonding.

Concrete technology has a higher porosity level, which is defined as the percentage of a material's volume taken up by pores. Concrete with a higher-strength grade has a lower carbon dioxide transfer coefficient and has a higher density, reduced porosity, and highly closed pores. As a result, the amount of carbon dioxide injected into the concrete is lowered.

The hydration process and the microstructure transformation of nano silica-included cement composite were studied.

The microstructure of cement mortar containing correctly scattered nanoparticles will be denser. Overall, it was discovered that the nanosilica interacted with lime throughout the cement hydration process, resulting in an increase in the concrete's mechanical strength and resilience.

Because their presence might increase the compressive and tensile strength of concrete, nanolimestone, and nanosilica concentrations were vital to the effectiveness of an ultra-high-performance concrete mixture.

Carbon nanotubes or CNT are currently used as a nanofiller in concrete due to their large surface area and unique material performance.

This nanomaterial boosted the ductility of concrete beams by around 150 percent. A qualitative microstructural study revealed the consistent distribution of CNT filaments throughout the concrete hydration products in complete batches. CNTs and graphene nanoplates were used to boost the strength properties of lightweight concrete.

In comparison to graphene nanoplates, concrete specimens made using CNTs have higher compressive strength. As a result, carbon nanotubes were identified as nanomaterials capable of improving the mechanical characteristics of concrete, such as compressive strength, tensile strength, flexural strength, ductility, fracture resistance, and enhanced performance electrical conductance.

Applications of nanomaterials in concrete. Image Credit: Saleem, H, Materials

Titanium dioxide is also another nanomaterial utilized in concrete. The addition of TiO2 to concrete can give it enough self-cleaning properties. Photocatalytic degradation of pollutants from the car and manufacturing emissions is conceivable with TiO2 infused concrete. Concrete structures with self-sensing and self-cleaning characteristics may be created by incorporating nano-TiO2 into cement matrices.

The use of particular nanostructured materials might help concrete constructions function better and last longer. Scientists are working to create a manufacturing process for generating nanoparticles on a commercial basis so that these materials may be made more simply and affordably.

Reference:

Saleem, H., et al. (2021). Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact. Novel Nanoparticles and Nanomaterials: From Design to Applications. Materials. Published: 25 October 2021. https://www.mdpi.com/1996-1944/14/21/6387

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.