The latest research indicates that porous materials have been implemented for various industrial purposes such as lightweight structural components, thermal structures, and high-temperature filters. The various fabrication methods are essential to obtain a specified density value of the porous body, morphology, and pore structure.

The latest research has indicated that high-temperature techniques have been implemented frequently in the past, however novel techniques involve high-pressure methods. The high-pressure techniques are more useful in obtaining porous biomaterials with superior mechanical strength and properties than the materials obtained via classical methods.

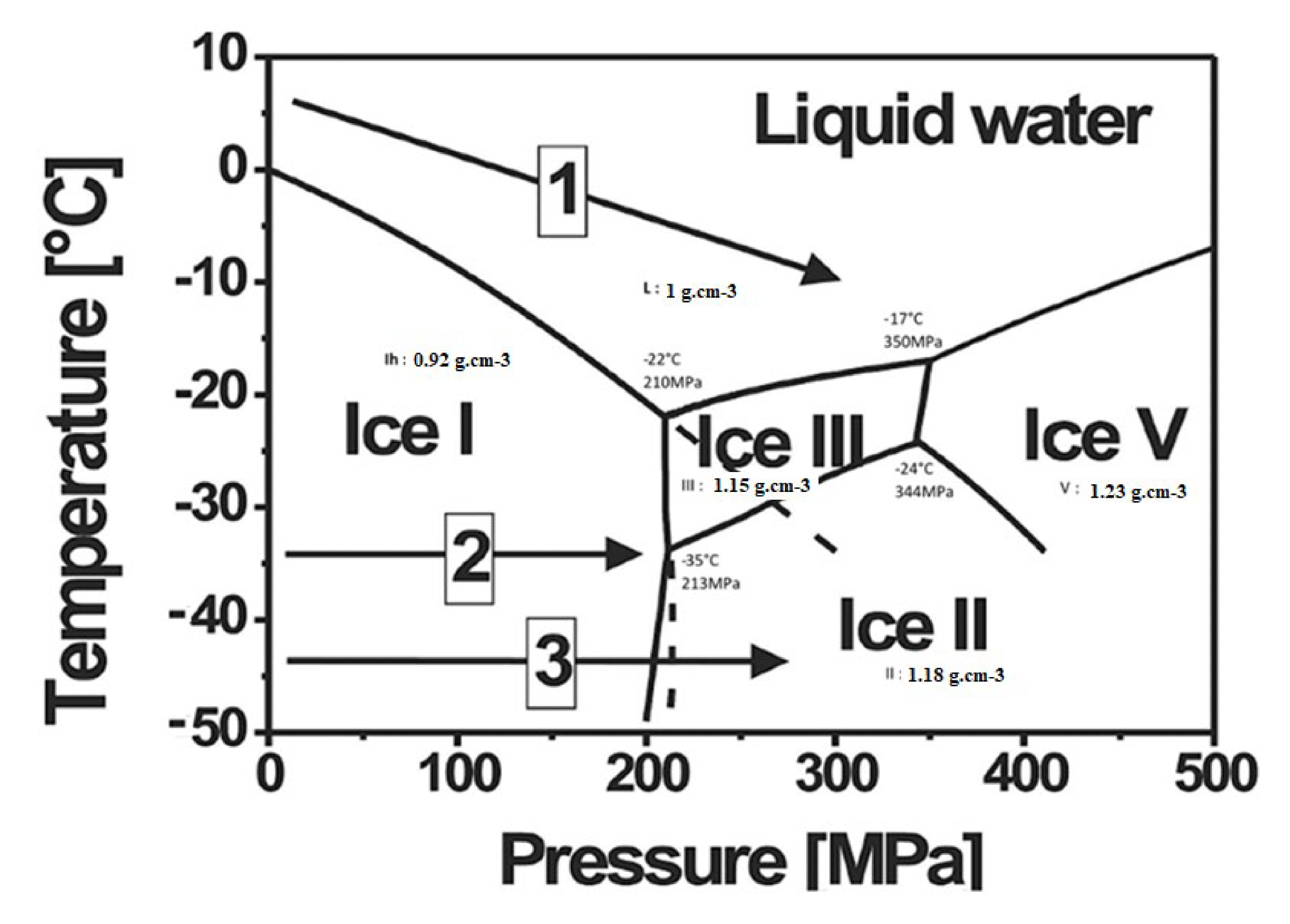

P-T diagram of water and their corresponding densities. Image Credit: Prakasam, M et al., Bioengineering

P-T diagram of water and their corresponding densities. Image Credit: Prakasam, M et al., Bioengineering

Porous Biomaterials

The porous materials, specifically ceramics and glasses, have piqued the interest of researchers due to their useful properties. The research has shown that high-pressure processes massively improve chemical bonding and physio-chemical properties. Various materials such as biodegradable polymers are utilized for tissue engineering processes. The biomedical process uses synthetic polymers and natural polymers. Other such materials include metallic biomaterials, bioactive glasses, and porous bioceramics.

Porous Scaffold Fabrication Process

Various methods are employed for scaffold fabrication processes. The novel high-pressure process termed freeze isostatic pressure is quite useful for high porous substances with superior properties. The processes used frequently include freeze dying, electrospinning, three-dimensional printing, and gas foaming. Although these classical techniques have been implemented for a very long time, the new technologies implementing high-pressure techniques have been far more advantageous in terms of mechanical and chemical properties.

Freeze Isostatic Process

This is also known as cold isostatic pressure (CIP), performed on a sample of hydrated CaCO3. The consolidation occurs either via dissolution or by the occurrence of plastic deformation. At the point of grain contact, stress concentration is high. It is quite identical to hydrothermal sintering methods. The process of plastic deformation occurs for metallic powders.

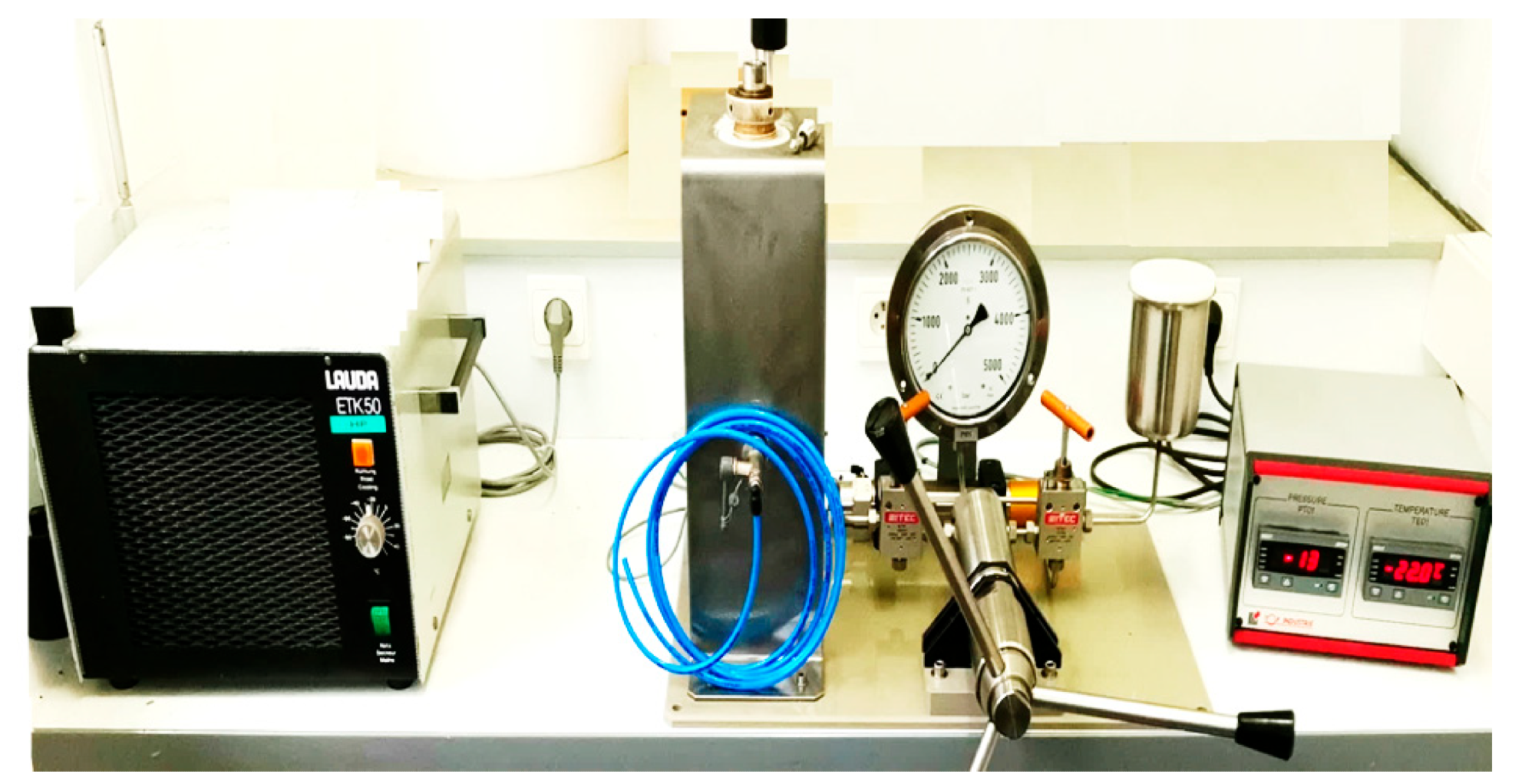

Freeze isostatic pressure equipment at ICMCB. Image Credit: Prakasam, M et al., Bioengineering

Isostatic Pressure at Positive Temperature

The pressure applied by a stagnant liquid or gas propagating in all dimensions is identical. The substance to be compressed is placed in a flexible tube, which is then immersed in a fluid medium. On this fluid, a certain force is given so that it functions uniformly in all directions of the form's regions. As a result, the substance is multi-directionally compressed, and the final substance's compression is determined by the substance's deformation.

Gas-Reinforced (GASAR) Technique

This is an abbreviation of “gas-reinforced” (Gas + Armirovat). This method involves the continuous crystallization of a gas-supersaturated melt at the freezing point of the eutectic mixture. Because of their increased gas absorption in the liquid state, metal crystallization and gas pore formation occur concurrently, resulting in the creation of a structured gas-eutectic mixture. This transition is quite similar to the standard recrystallization process.

Hydrothermal Sintering (HyS)

Hydrothermal sintering was characterized in 1972 as typical hot sintering in the presence of water in hydrothermal circumstances. The goal of this approach is densification and solidifying materials in a restricted pressurized media at a low temperature, with pressure and solvent present. This method allows for the consolidation of massive, porous, and multilayer monoliths.

Thermosensitive Materials with High Hydrostatic Pressure

High hydrostatic pressure (HHP) treatment is the subject of recent investigation, which is covered in this paper. HHP treatment was first established for food in the early 1990s to reduce microbial inactivation and extend shelf life. Currently, HHP is a modern technology with a wide range of applications in biosciences.

A sealed high-pressure container loaded with fluids functioning as a transmission media is squeezed by a compressor or by reducing the volume of the container to provide isostatic pressure in the HHP process.

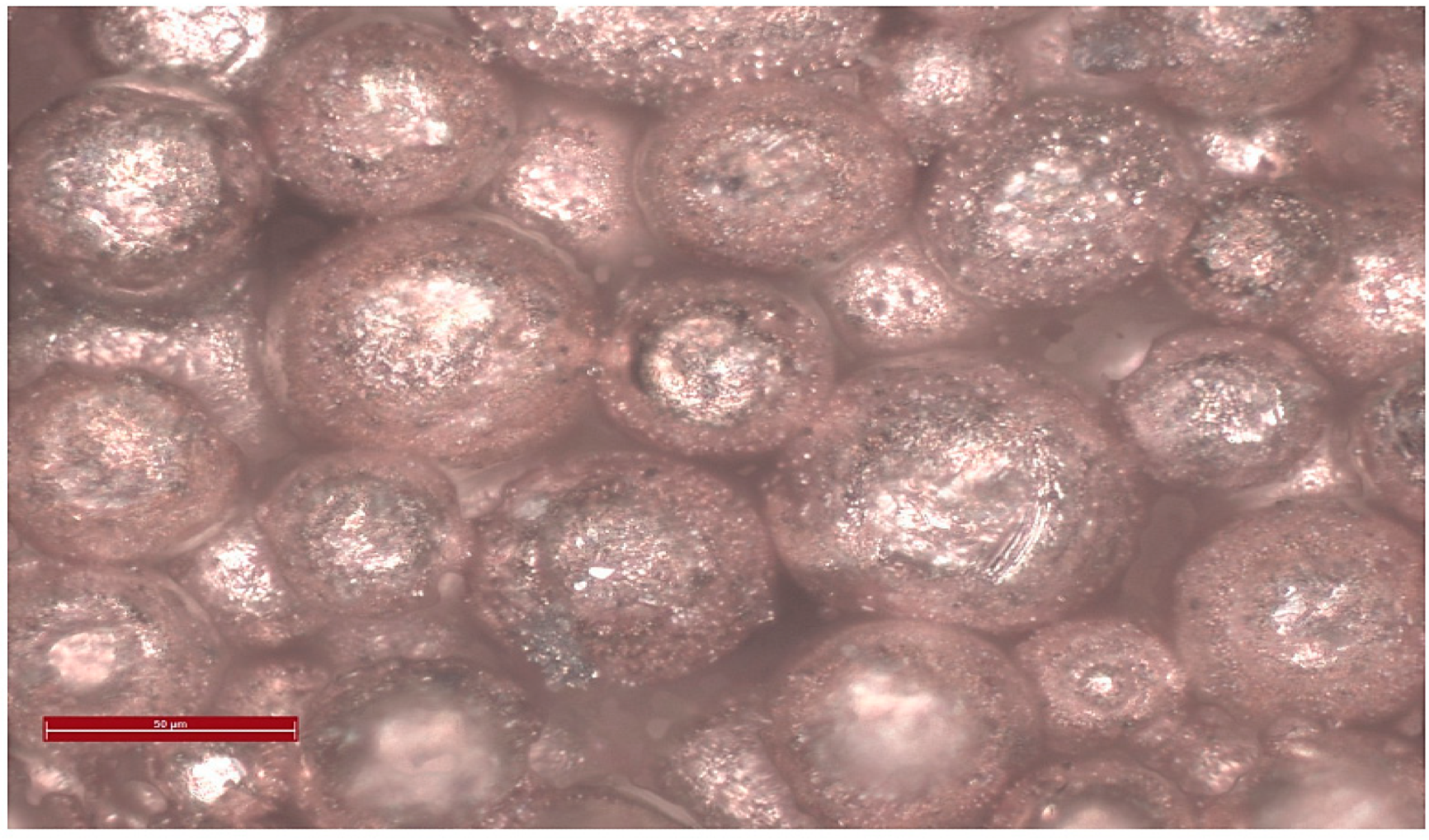

Microstructure of porous Cu samples obtained by hydrothermal sintering. Image Credit: Prakasam, M et al., Bioengineering

Freeze Isostatic Pressure (FIP)

The FIP experiment was carried out on AlfaAesar crystalline spherical SiO2 powder with a 1.5 m diameter to produce monoliths of porous silica such as biomaterial models that might contain medicinal compounds, which are primarily disintegrated at temperatures higher than human corporal temperature. We were able to see how the dispersion of the solvent in the powder is not uniform due to coalescence using the tomography technique.

In short, the high-pressure processes have been declared one of the best novel techniques as they offer superior mechanical properties. Under low temperatures, the manufacturing of porous biomaterials with higher mechanical strength is made possible at high pressure.

References

Prakasam, M., Silvain, J. F., & Largeteau, A. (2021). Innovative High-Pressure Fabrication Processes for Porous Biomaterials-A Review. Bioengineering, 170. https://www.mdpi.com/2306-5354/8/11/170

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.