Liquid crystals have properties that are more intriguing than other smart materials, which can be employed to print objects that are sensitive to external stimuli. This is considered in new research in the journal Advanced Materials.

Study: 4D Printing of Liquid Crystals: What's Right for Me?. Image Credit: Ad Gr/Shutterstock.com

Three-dimensional printing is a kind of additive manufacturing technique through which objects are printed layer by layer. This is a bottom-up technique of manufacturing that involves the use of various methodologies, materials, and equipment.

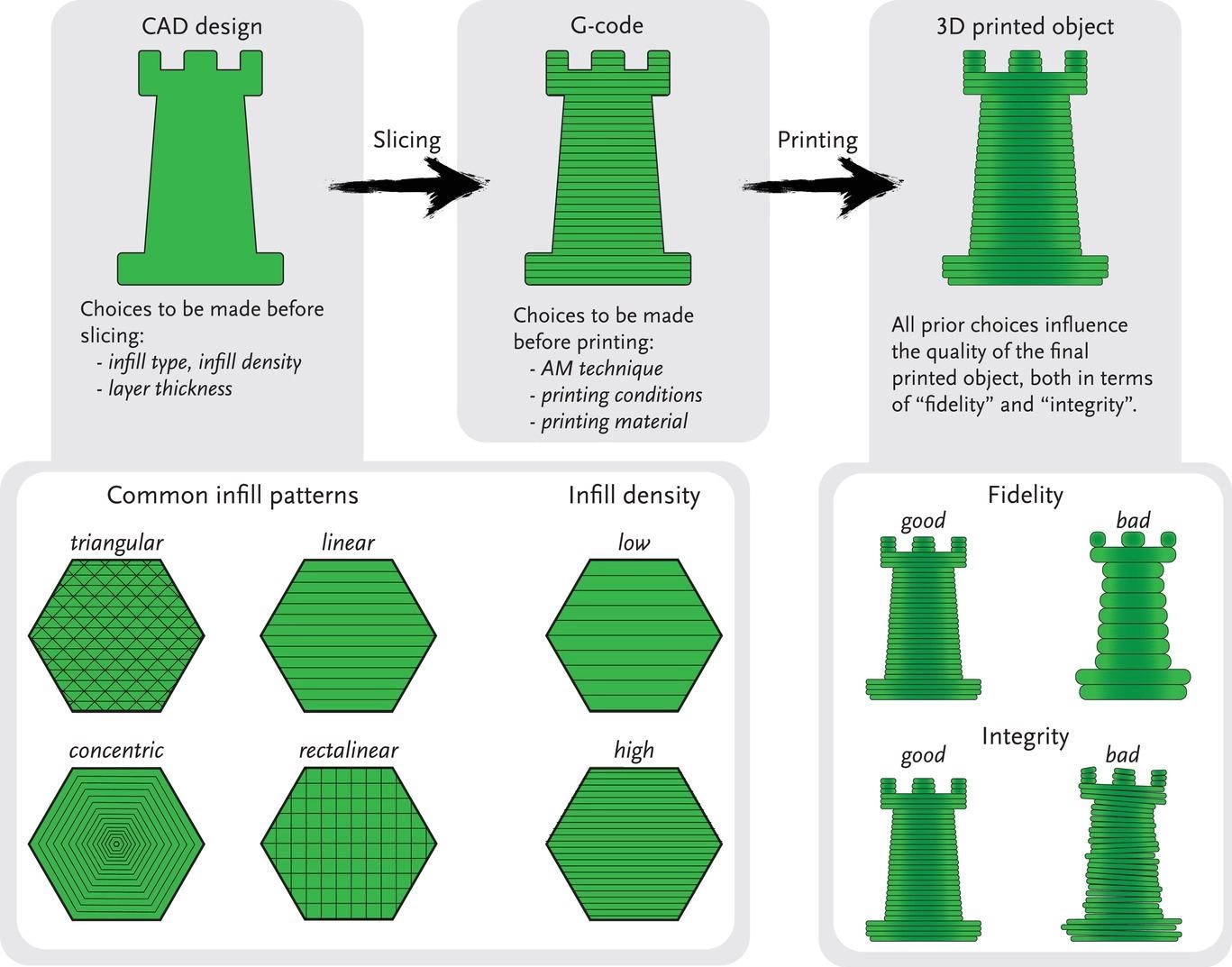

The additive manufacturing process involves Computer-Aided Design (CAD) programming that is used to provide instruction to the printing equipment to print the three-dimensional object.

Objects from a micrometer range to tens of meter range could be printed through three-dimensional printing. Over the years, this printing technique has evolved for several applications in industries based on aviation, construction, garments, biomedical appliances, and tissue engineering.

What is Four-Dimensional Printing?

The use of smart materials that can be attuned to geometry as well as responsivity are taken for three-dimensional printing; this technique is referred to as four-dimensional printing, the fourth dimension being the programmable response of the material under external stimuli.

Four-dimensional printing has several applications in soft robotics, implantable medical devices, and consumer products. This is achieved by locally programming the smart material to manipulate the response of the macrostructure printed.

Schematic describing the process from a CAD design to a 3D printed object. Image Credit: Pozo et. al., Advanced Materials

A few of the smart materials that were studied are hydrogel, shape memory polymers, polysiloxane thermosets, and liquid crystalline (LC) materials. Hydrogels show good reversible deformation by swelling and de-swelling, which is programmable. However, its reversibility after deformation reduces in dry environments.

Polysiloxane thermoset lacks versatility in properties, whereas shape memory polymers need reprogramming after every deformation or actuation. There are one or two other drawbacks with other smart materials, however liquid crystal has shown the combined positive characteristics of all smart materials.

Liquid Crystal, a Smart Material:

Liquid crystals are widely used smart materials that can be preprogrammed, are reversible after deformation, and work both in dry and wet environments. Their applications include water purification, optical sensing, display technology, energy management, and use in artificial muscles.

Liquid crystals contain molecules called mesogens, that under external stimuli align themselves and crosslink in a particular direction. Several methods have been developed for the orientation of monomeric or oligomeric liquid crystal elastomers.

4D Printing of Liquid Crystal:

A review article published by a group from the Eindhoven University of Technology in the Netherlands explains the various four-dimensional printing techniques of liquid crystals and the various parameters affecting the final printed object.

Vat polymerization and three-dimensional extrusion are the two techniques of additive manufacturing used for the four-dimensional printing of objects through liquid crystals. These two techniques are for two different classes of liquid crystals depending, upon the molecular weight.

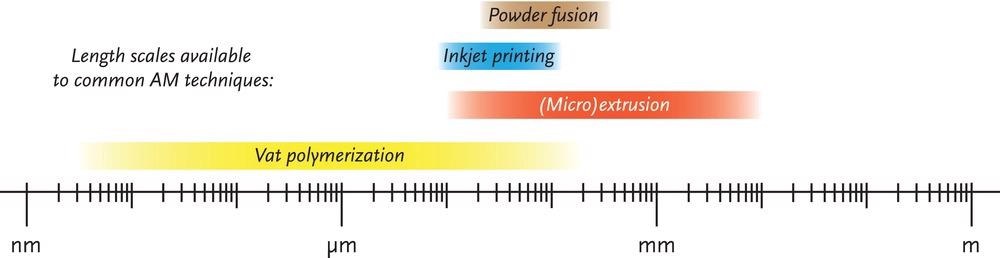

The resolution of vat polymerization is more than 3D extrusion, for which vat extrusion is employed for micro-sized objects while the other is used for larger objects. Vat polymerization uses photo resisting to initiate the crosslinking of molecules.

Overview of the most common additive manufacturing type classified by the resolution typically achieved. Image Credit: Pozo et. al., Advanced Materials

3D extrusion forces a thread of material called filament out of the nozzle that places filament on the line or over the previously deposited layer. After the entire printing, the drying or curing process completes the object.

The actuation can be achieved through several techniques such as light triggering, humidity triggering, and electrical or magnetic triggering.

In vat polymerization, various intermediate processes result in the final printed object, such as liquid crystal alignment, layer spacing, infilling, laser power, scanning speed, and temperature.

In the case of three-dimensional extrusion, the printing process includes various parameters such as infill pattern, nozzle diameter, printing temperature, speed of extrusion, and synthesis of liquid crystal ink.

Applications of 4D Printed LC Structures:

Four-dimensional printed liquid crystals are printed to soft robots used as artificial muscles that could perform the lifting of objects against gravity. Photonic devices are another application, including the optical lens.

Another application is use in biomedical implants, as these materials have shown slight biocompatibility. Significant future applications of four-dimensional printed liquid crystal in bio-implants are possible, upon receiving the necessary approvals.

Future of Liquid crystal four-dimensional printing:

Liquid crystal has recently been introduced in the four-dimensional printing sector, hence there is lot more to explore in this area. Different kinds of stimuli, chemistry involving mesogens, exploration of self-healing materials, and recyclability of liquid crystals are yet to be explored.

The variations and upgradations of the additive printing techniques for four-dimensional printing of liquid crystal is also an area that needs more exploration.

More developments into this bright field of liquid crystal four-dimensional printing require more researchers from different areas, combining different perspectives.

References and Further Reading:

Pozo et. al. (2021) 4D Printing of Liquid Crystals: What's Right for Me? Advanced Materials https://onlinelibrary.wiley.com/doi/10.1002/adma.202104390

Ambulo et. al. (2017) Four-dimensional printing of liquid crystal elastomers ACS applied materials & interfaces 9 37332. https://pubs.acs.org/doi/10.1021/acsami.7b11851

Ngo et. al. (2018) Additive manufacturing (3D printing): A review of materials, methods, applications and challenges Composites Part B: Engineering 143 172. https://www.sciencedirect.com/science/article/pii/S1359836817342944

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.