Plastic waste in the oceans is a significant problem that will require innovative solutions to tackle. A research paper published by PNAS has demonstrated the feasibility of creating fuel from collected waste which will significantly improve the entire process of plastic waste removal.

Study: Thermodynamic feasibility of shipboard conversion of marine plastics to blue diesel for self-powered ocean cleanup. Image Credit: Rich Carey/Shutterstock.com

Plastic Waste: A Growing Problem

There are estimated to be over 5 trillion pieces of plastic in the oceans, with millions of tons of waste entering them every year. The problem is almost immeasurable, with larger pieces of plastic degrading into smaller and smaller pieces that then enter the food chain. As more waste is created, the problem becomes compounded, and cleanup efforts become a moving target that is going in the wrong direction.

The production of plastic is predicted to remain for several years, so it is urgent that current waste be eliminated to prevent a spiraling problem. This will help to protect vital ecosystems and ensure the safety of marine food production.

The Problem with Current Methods of Waste Removal

Currently, several technologies have been developed to clean the plastic waste from oceans. However, despite some progress, cleanup operations are limited by the amount of plastic waste that can be stored onboard ships and the need for refueling and resupplying.

Round trips can take a long time, especially if the port where disposal occurs is thousands of kilometers from the cleanup site. Add to this the problem with emissions from fuel, and it is obvious that the process is lacking in key areas of efficiency and sustainability.

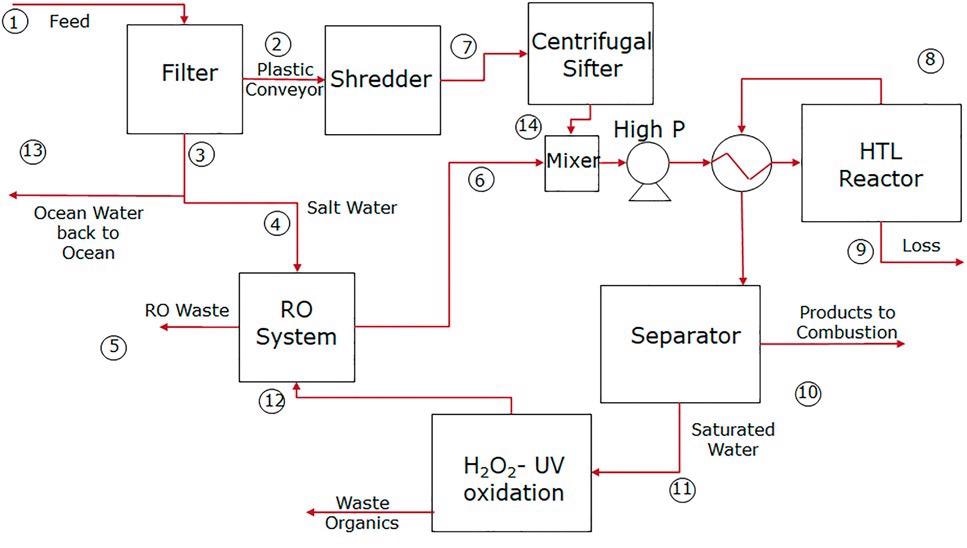

Conceptual design of a shipboard HTL-based process for converting ocean-borne plastics into usable fuel: process flow diagram. The entire process is designed to fit within a standard 20-ft shipping container. Image Credit: Belden, E.R et al, PNAS

A better method is needed if the sector is to be able to realize its full potential. One way to remove storage issues and the time needed to refuel is to use plastic waste itself to provide fuel for onboard operations.

Using Plastic Waste to Create Blue Diesel

Using plastic waste to create fuel is a novel idea, but one which means that the process of removal and remediation has a circular element in fuel production and use. Plastic waste has a similar energy profile to hydrocarbons, and by using this sadly abundant resource, the need to produce petroleum-based fuels is eliminated.

The paper proposed a process based on hydrothermal liquefaction, which uses heat and pressure to turn plastics into fuel, retrieving the polymers and taking them out of the environment. The oil yield is over 90%, even without catalysts. Furthermore, solid byproduct yield is low. Another method explored by the research team was pyrolysis, but this has significant disadvantages compared to hydrothermal liquefaction.

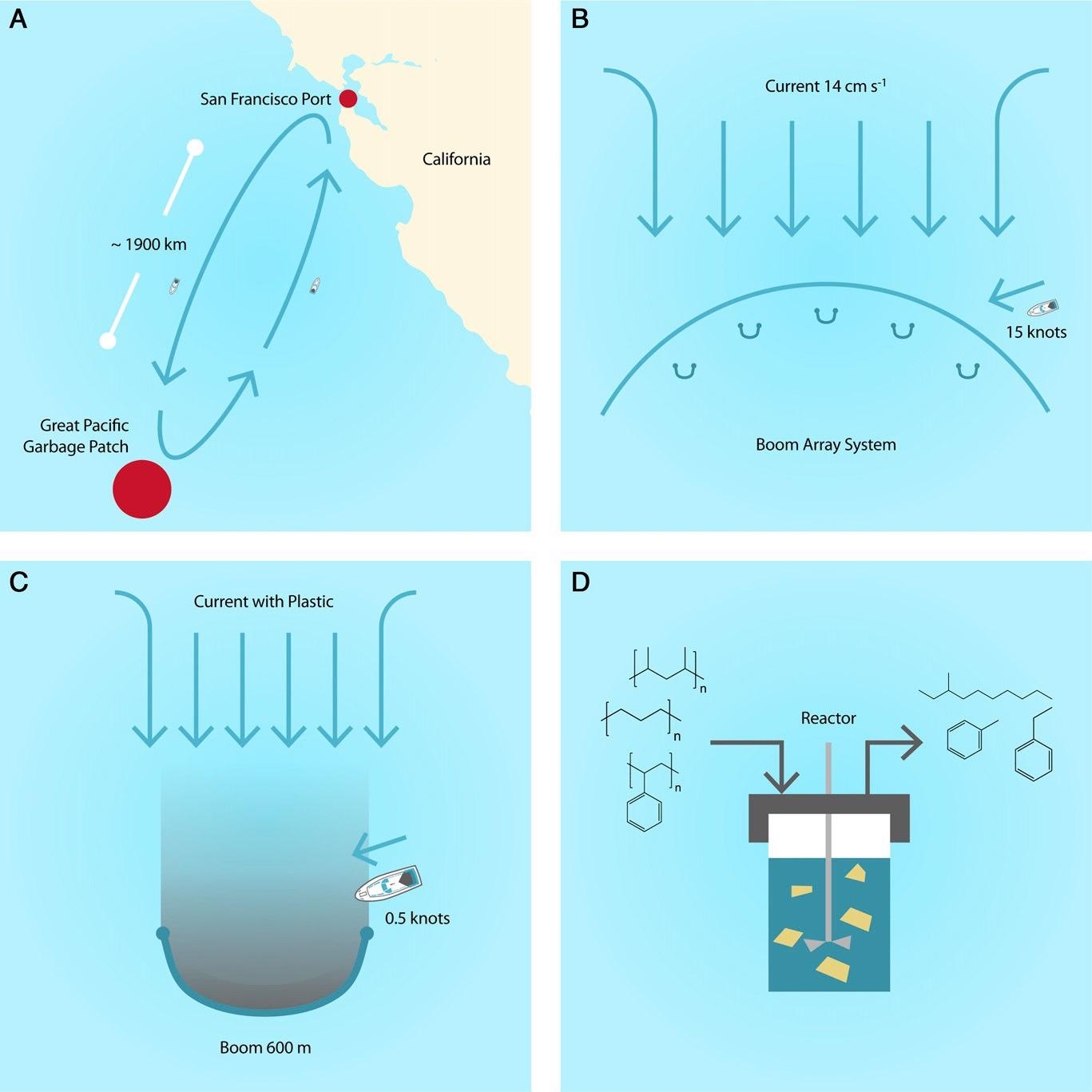

Overview of the process for plastic removal out of the GPGP showing (A) the total system overview, (B) part of the system of collection booms, (C) a single collection boom, and (D) the HTL reactor. Image Credit: Rich Carey/Shutterstock.com

To make the process commercially viable, the energy produced must be more than the plastic needed for fuel production. However, advances in technology and data analysis will help to realize this. The research ran simulations for common plastics – Polyethylene and polypropylene – as well as a mixture of both. A mix of PP and PE was found to be the most promising, having the highest yield whilst generating no solid byproducts.

Using this process, retrieval rates of between 230 and 11,500 tons of plastic waste removal annually were modeled by the research team. The range in models depended on the surface concentration of oceanic plastics. Further studies will be needed to assess this.

Advantages and Key Challenges

Creating fuel onboard ships has several key advantages. Aside from the aforementioned advantages for operational efficiency, the process is much more sustainable than current fuel production. The emissions from blue diesel (so-called because it has a marine origin) are a fraction of the emissions produced by traditional fuel manufacture.

Furthermore, congestion at ports and the risk of oil spills close to shore are reduced by self-refueling ships.

However, challenges in the technology will need to be addressed. Aside from the production of energy exceeding waste needed for fuel, scalability is a vital consideration if the process is to be commercially viable. Further considerations include how the technology can be implemented on onboard ships safely considering physical and economic constraints.

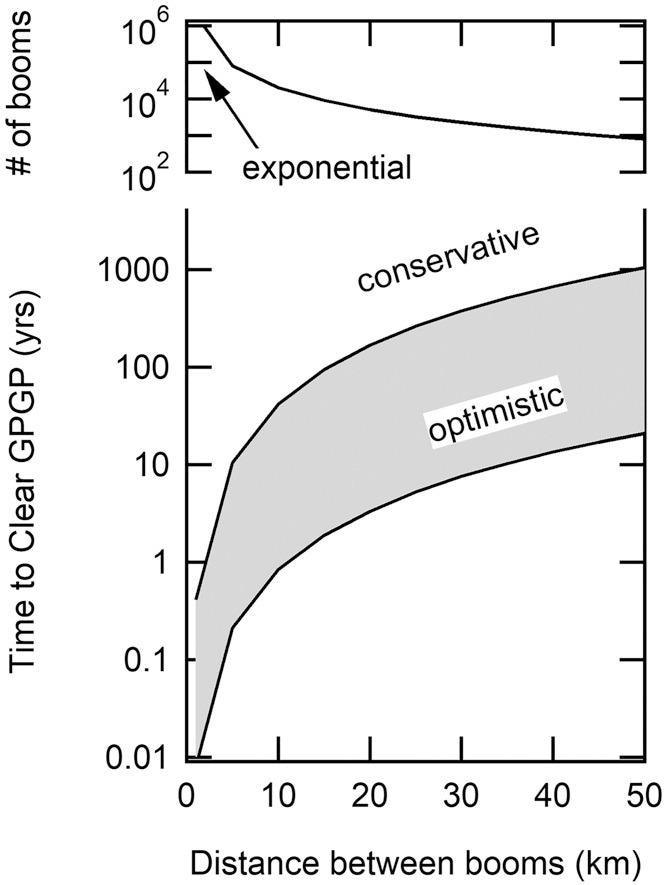

Estimation of the time required to completely clear the GPGP based on high (2,500 g.km-2) and low (50 g.km-2) concentration estimations (1) for plastic within the GPGP for deployment distance between booms of 1 km to 50 km and the corresponding number of booms deployed. Image Credit: Rich Carey/Shutterstock.com

A framework for evaluating the implications of this shipboard process was also presented by the research team. This will need to be developed as new data is gathered. Additionally, gaps in scientific knowledge of the nature of marine plastic waste will need to be addressed.

The Future

The oceans are becoming more polluted by human activity. Efforts must be stepped up to increase removal rates if the worst effects of environmental damage are to be mitigated. The ability for ships to convert existing plastic waste into fuel will be a huge step forward for the industry, creating more efficient, sustainable, and safer waste removal operations in the future.

Further Reading

Belden, E.R et al. (2021) Thermodynamic feasibility of shipboard conversion of marine plastics to blue diesel for self-powered ocean cleanup [online] PNAS.org. Available at: https://www.pnas.org/content/118/46/e2107250118

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.