Medical science has progressed significantly in recent decades with innovative solutions to previously hard-to-treat conditions. Now, a paper published in Materials has demonstrated a method for regenerating bone tissue using 3D printing that could revolutionize regenerative medicine.

Study: 3D Printing in Alginic Acid Bath of In-Situ Crosslinked Collagen Composite Scaffolds. Image Credit: Gorodenkoff/Shutterstock.com

Using Bio-active Materials in Regenerative Medicine

Regenerative medicine is a branch of medical science wherein therapies are developed to replace tissues, organs, and cells that are compromised by disease, defectiveness, or injury. It is a field of medical science that promises to provide relief for patients with previously difficult to treat conditions and injuries.

Nanostructured bio-active materials have received attention in the field due to their regenerative abilities. They replicate the properties of natural tissues and mimic their architecture. These advanced medical materials can be processed and applied using 3D printing and other technologies.

Regenerating Bone Tissue: A Critical Medical Advance

It is well-known that aging leads to progressive health problems. Conditions such as osteoporosis occur as patients age, causing suffering for individuals and an increased burden on healthcare. Traditional treatments include bone grafts, and aside from this therapy, other methods fail to mimic the properties and architecture of natural tissues. For this reason, several new research areas including bone-tissue engineering have been developed.

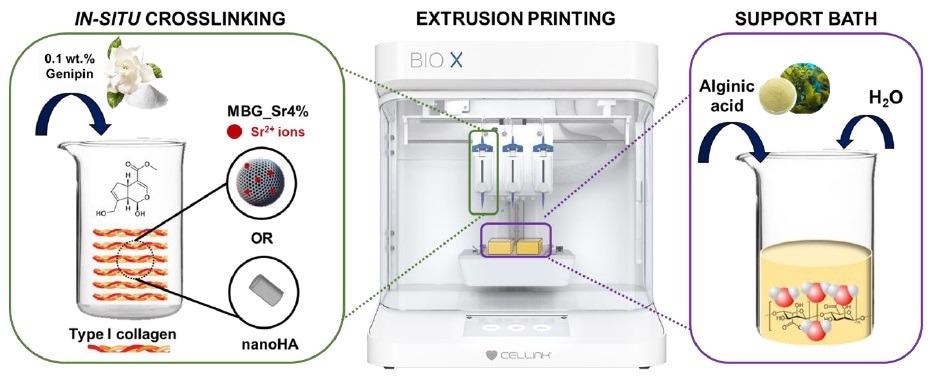

Schematic representation of the developed methodology. Image Credit: Melo, P et al., Materials

The field of bone-tissue engineering is concerned with the development of biomimetic devices that both support bone growth and induce regeneration. Advanced bio-active materials which are 3D printed into functional scaffolds are used in bone-tissue engineering technologies.

These interact with the target tissues and induce a therapeutic response. Composite materials are based on type 1 collagen and hydroxyapatites (also commonly used in dentistry) as these are the main components of bone tissue.

An osteopathic response is generated by the composite biomimicking materials, inducing growth, proliferation, and even differentiation. This leads to regeneration of the bone tissue. A commonly used 3D printing technique in material fabrication in the field of bone tissue engineering is extrusion.

This is due to its versatility and scalability. However, several key challenges remain in the fabrication of strong, durable biomimicking materials for bone regeneration applications.

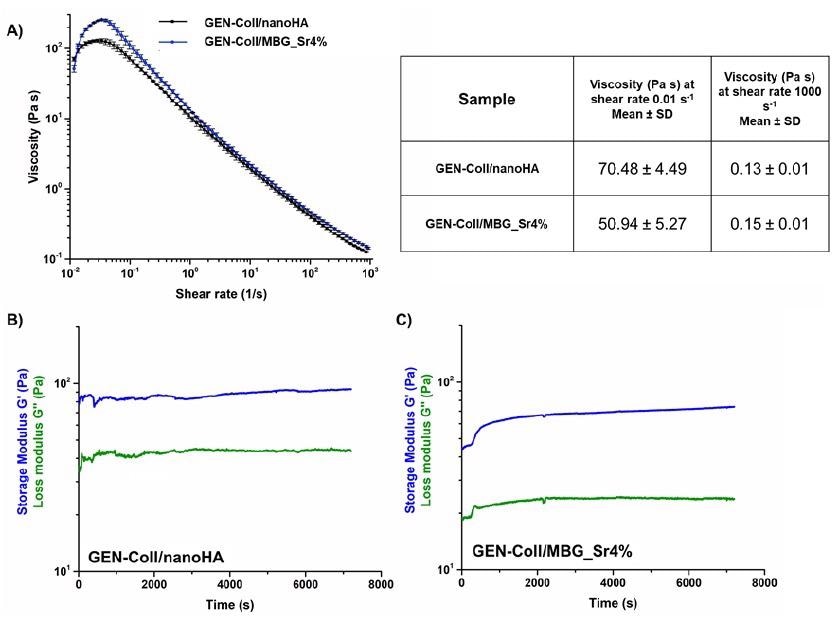

Variation of the viscosity (A), and visco-elastic properties of GEN-Coll/nanoHA (B) and GEN-Coll/MBG_Sr4%, (C) at 10 °C. Image Credit: Melo, P et al., Materials

Type 1 Bovine Collagen Formations: Promising Bio-Active Materials for Regenerating Human Bone Tissue

Type 1 bovine collagen formations are promising materials for regenerating damaged or diseased bone tissue. These bio-active materials contain functional, enriched nanoparticles and are easily 3D printed using support baths. However, there are a few issues with their use. They are difficult to fully remove after the printing process, and crosslinking agents used to improve the structural integrity of their scaffolds can cause loss of geometrical definition and partial collapse of printed constructs.

Alternative processes are needed to overcome the limitations of these biomaterials. Now, a team led by Priscila Melo has proposed a method to create stronger, more suitable bio-active materials based on bovine collagen that will help revolutionize techniques to regenerate human bone tissue.

Improving the Process

The process reported in the paper aims to improve the properties of bovine collagen formations. Crosslinking agents are added to the printing formulations, promoting cross-linking in the constructs before they are removed from the support bath. The chosen cross-linking agent was genipin, which by triggering in-situ cross-linking improves the stability of the 3D printed scaffold structure of the collagen.

The solution used for the support bath was alginic acid, which the research found sustained the 3D printed structures of the collagen material, as well as being easy to remove at 37 oC, which allows for stable processing of structures with high-resolution geometries. The method was developed using previously established protocols.

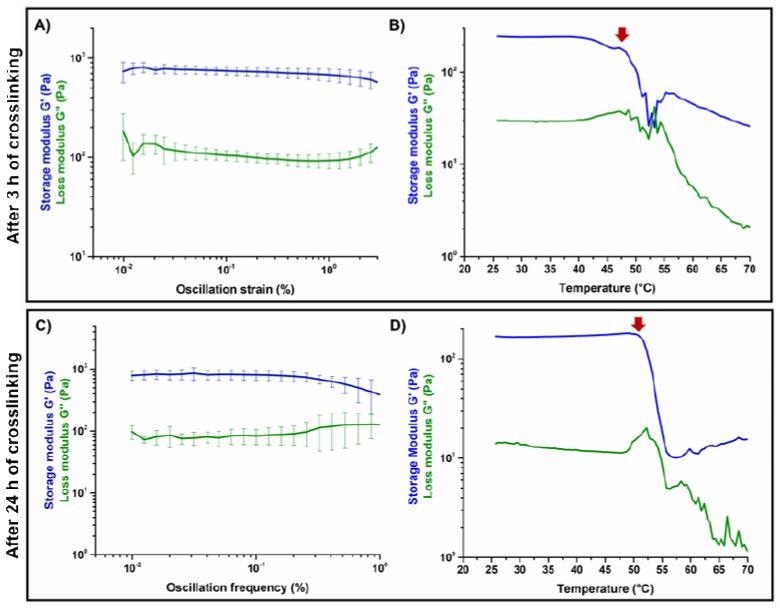

Amplitude sweep test (A,C) and temperature ramps (B,D) performed on GEN-Coll/nanoHA after 3 h and 24 h of incubation at 37 °C. Image Credit: Melo, P et al., Materials

Honeycomb and grid geometries were chosen to assess the material’s printability. Several trials were conducted with different parameters to provide good levels of control and provide an understanding of the results. The effects of each parameter on printing fidelity and the resolution of the final scaffolding structure formed the basis of the changes.

The study concluded that the parameters would need fine-tuning to achieve desired results since they are intertwined.

Visual analysis of the printed scaffolds confirmed that geometrical replication was successfully realized by the printing process. Well-defined strands and pores were produced. Morphology was analyzed by FE-SEM after lyophilization, which showed that the nanoparticles were successfully distributed within the matrix.

These results demonstrated that 3D printing collagenous materials with the process showed favorable results for its use in regenerating bone tissue.

The Future

The research published online in Materials shows a promising direction for the creation of bio-mimicking 3D printed materials with improved mechanical and physical properties. Further studies to fine-tune the process are needed, but this novel process has enormous potential.

Further Reading

Melo, P et al. (2021) 3D Printing in Alginic Acid Bath of In-Situ Crosslinked Collagen Composite Scaffolds [online] Materials 14(21) 6270 | mdpi.com. Available at: https://www.mdpi.com/1996-1944/14/21/6720/htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.