Nanoparticles have been subjected to intensive research and ever-growing attention due to the fact they demonstrate unique and varied chemical and physical properties regardless of their tiny size (1 to 100 nm), and demonstrate vast application potential. Their production has been further expanded upon in the journal Materials Today.

Study: Green synthesis of copper nanoparticles using artemisia plant extract. Image Credit: Kaprisova/Shutterstock.com

Nanoparticle manufacturing can be done by either breaking down larger particles or via a controlled assembly process. However, one of the downsides to nanoparticle production is that it can be both expensive and have a detrimental impact on the environment due to the result of costly chemicals.

Now, a team of researchers at the University of Babylon, Iraq have developed an eco-friendly, low-cost plant-based copper nanoparticle production method. This is an exciting development considering that copper nanoparticles have an extensive range of applications in both research and real-world scenarios.

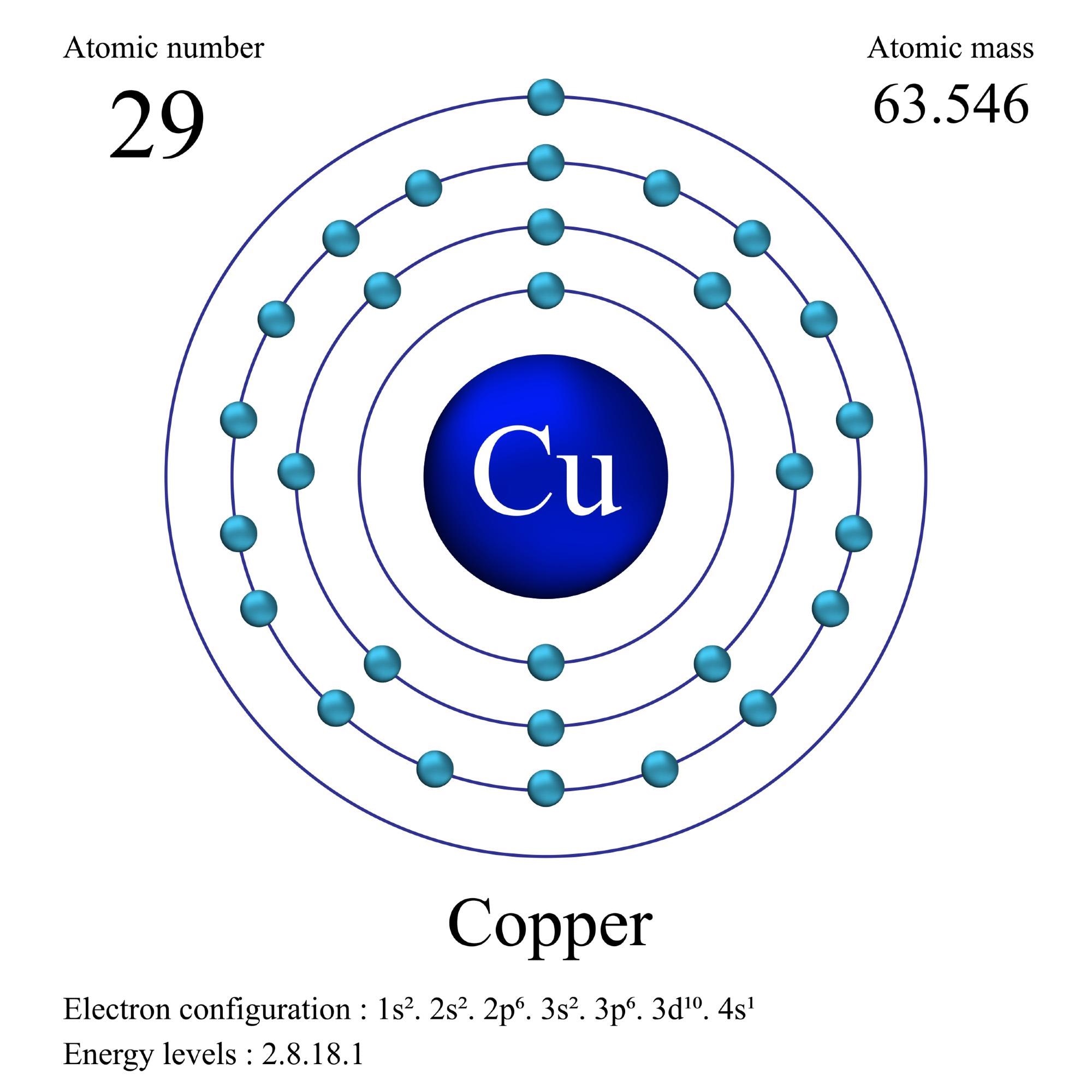

Nano Copper

Copper nanoparticles display unique characteristics and can act as antibiotic, anti-microbial, and anti-fungal agents when added to other materials as well as help strengthen metal alloys.

They can also be used as heat sinks in electronic technology-based scenarios as well as being an effective catalyst: as a result of their great catalytic potential, copper nano can be incorporated in to biosensors and electrochemical sensors.

Thus, developing an eco-friendly, low-cost production method not only has a positive environmental influence, but could also have a significant impact on various fields including biomedicine, electronics, and catalytic chemical processing.

Plant-Based Copper

While the term ‘plant-based’ commonly finds itself in the current lexicon in relation to food- and diet, plant-based copper nanoparticles add a different meaning to the term.

Using plants has a number of advantages, such as eliminating the need for culture preparation and isolation maintenance, being relatively inexpensive, eco-friendly, stable, safe, and non-toxic, reduced production times. Additionally, plant-based materials are relatively easy to scale up when it comes to the large-scale production of nanoparticles.

The team, led by Professor Mahmood Ali Abed Al-Khafaji of the university of Babylon’s College of Science Chemistry Department, collected a batch of fresh Artemisia leaves from a local marketplace.

Artemisia leaves are a genus of aromatic herbs and include wormwood, sagebrush, and tarragon. They are often harvested for use in medicines as herbal remedies as well as in the production of certain alcoholic beverages such as absinthe and vermouth.

Once they had acquired the leaves they then washed them before drying under a sunshade to get rid of all of the moisture. Once the leaves were completely dry, they then crushed the leaves using a mechanical grinder before cooking the powder in distilled water.

To synthesize the copper nanoparticles, the team then added plant extracts and purified the mixture using a filter. The filtered mixture was then dried which produced a brown powder-like substance from which the nano copper was extracted.

Anti-Bacterial Analysis

The team conducted an anti-bacterial study as part of their research which confirmed that the copper nano demonstrated anti-microbial features: “During the production of Cu NPs, polyphenols played a significant role as reducing and capping agents. Cu NPs’ broad inhibition zone against pathogens demonstrates their high activity for infectious illnesses produced by the microorganisms examined,” Al-Khafaji explained.

Image Credit: saran insawat/Shutterstock.com

Furthermore, the team used several tools including scanning electron microscopy (SEM) and Fourier Transform Infrared (FTIR) to evaluate and validate the production method. They discovered that as a by-process, some of the copper atoms on the surface of the nanoparticles had oxidized with the air to create copper oxides.

Overall the copper nano demonstrated an excellent range of antibacterial properties against two specific bacteria types – E. Coli and Bacillus subtilis – and demonstrated good levels of efficacy. “The presence of bioactive chemicals on the surface of Cu NPs as capping and stabilizing agents may be the primary cause for nano copper’s antibacterial activity,” says Al-Khafaji.

Consequently, the research team was able to produce plant-based copper nanoparticles that demonstrate the success of their environmentally friendly, low-cost, and relatively simple method. The result show that when combined with plant extracts the nano copper may have beneficial applications in the area of medicine for the treatment of infectious illnesses.

This method demonstrates the benefits of plant-based alternatives in material science, and could also pave the way for other green methods of nanoparticle production and open the door to plant-based nanomaterials becoming part of the future of technology and industry.

References:

Mahmood Ali Abed Al-Khafaji, Rana A.K. Al-Refai'a, & Oda Mizil Yasser Al-Zamely. ‘Green synthesis of copper nanoparticles using artemisia plant extract’. Materials Today: Proceedings. November 2021. https://www.sciencedirect.com/science/article/pii/S2214785321065573?via%3Dihub

‘Copper (Cu) Nanoparticles - Properties, Applications’ https://www.azonano.com/article.aspx?ArticleID=3271

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.