.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyNov 12 2021

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyNov 12 2021It is essential to develop carbon materials with good graphitic structure and physicochemical performance using precursors from renewable and sustainable sources, as considered in the journal Diamond and Related Materials.

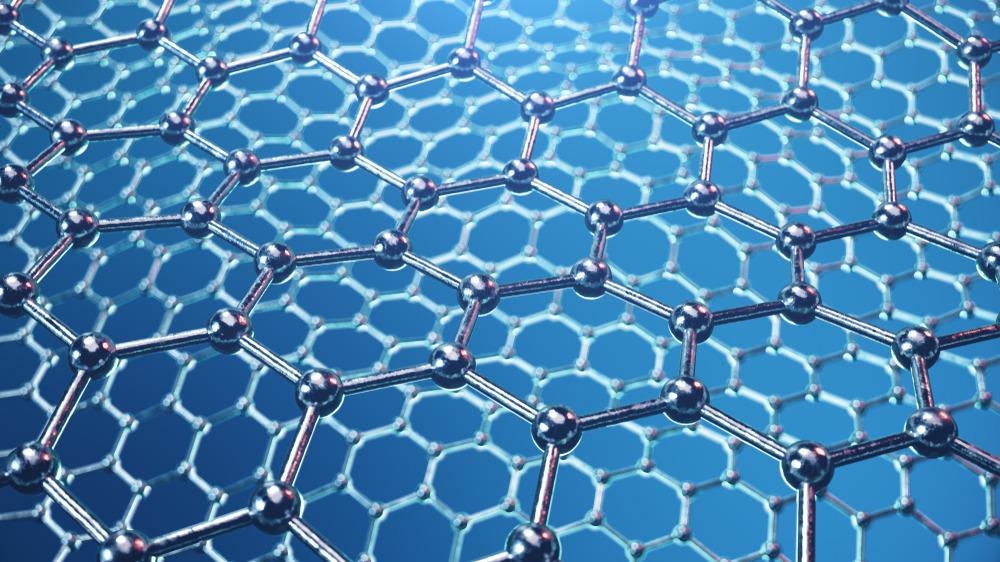

Study: Formation mechanism of nano graphitic structures during microwave catalytic graphitization of activated carbon. Image Credit: Rost9/Shutterstock.com

Graphitic carbon has been in use since the 1990s due to its high electrical and thermal conductivity. Apart from these, properties such as ordered crystalline structure and physiochemical stability are helpful while choosing carbon materials for ion diffusion.

What is Catalytic Graphitization?

Previous studies used transition metals such as Ni, Fe, Co, and others to produce graphitic carbon materials. Catalytic graphitization is a complex process involving many chemical as well as physical changes. Metal catalysts used in graphitization lower the activation energy and convert disordered carbon into a layered structure. This allows graphitization reactions to occur at lower temperatures.

Catalytic graphitization can be performed using two different mechanisms. While the first one involves dissolution-precipitation for metals such as Ni, Fe, Mn, and Al, the second one involves carbide formation-decomposition for Mo, W, Ti, Ca, and V. In this first mechanism, the dissolution of carbon is carried out at high temperatures, and graphitic structures are precipitated during the cooling process.

Impact of Various Parameters on Low-Temperature Catalytic Graphitization

A coconut shell-based AC with a particle size of 53–88 μm was used as the amorphous carbon in this recent study. The impact of various parameters like catalyst (Ni) loading, holding time, temperature, and catalyst salt precursor on the low-temperature graphitization of AC was assessed in the work.

The study indicated that the weight of Ni, temperature, and holding time created an impact on the degree of graphitization. As per the results, an increase in Ni loading from 2% to 20% increased the graphitization degree from 33wt% to 81wt% and raised the intensity of the (002) carbon peak.

The higher the degree of graphitization, the better the interaction between catalyst Ni and amorphous carbon. Apart from the above parameters, temperature also played an important role in the graphitization process. When the temperature increased from 900C to 1400C, the degree of graphitization went up from 57wt% to 81wt%.

The isothermal holding time was not found to impact the Raman intensities or the degree of graphitization. However, the holding time of 30 min at 1400 C increased the degree of graphitization from 71wt% to 94wt%. The study used various Ni-based salts such as NiCl2, Ni(NO3)2, and Ni(CH3CO2)2 to prepare AC samples. The lowest degree of graphitization—56wt%—was observed with NiCl2. Ni(NO3)2 and Ni(CH3, CO2)2 showed comparatively higher degrees of graphitization at 82wt% and 85wt%, respectively.

Raman spectroscopy analysis was used to understand the carbon structure and ordering of synthetic graphite. The Brunauer-Emmett-Teller (BET) theory was used to analyze changes in specific surface area and pore structure of GAC. The overall results showed that the AC surface area decreased at higher Ni loadings and with the degree of graphitization.

X-ray diffraction and transmission electron microscopy revealed that dissolution-precipitation and metal-induced graphitization were the primary mechanisms for the formation of graphitized carbon. It was also found that the graphitization rate under microwave irradiation is significantly higher than that under conventional heating.

Rietveld refinement was used for calculating the degree of graphitization under different heating methods. The degree of graphitization of GAC by microwave was 81wt% while that by electric oven was 36wt%. It was also observed that the power consumption of various heating methods played a significant role in the scalability of the process.

Degree of Graphitization is Impacted by Ni Loading, Higher Temperature, and Longer Holding Time

In conclusion, microwave irradiation had the most impact on the mechanism catalytic graphitization of amorphous carbon at low temperatures. The crystalline structure of graphite was mainly influenced by the type of Ni precursor used, graphitization temperature, and Ni loading. The ON/OFF heating mode in microwave heating improved the dissolution-precipitation cycles by promoting rapid temperature fluctuations and particle-level catalyst supersaturation.

The study concluded that the degree of graphitization is purely based on three factors - Ni loading, higher temperature, and longer holding time. Also, Ni precursors such as (NO3)2 and Ni(CH3CO2)2 increased the degree of graphitization.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Rish S, et al. Formation mechanism of nano graphitic structures during microwave catalytic graphitization of activated carbon. Diam. Rel. Mat. 2021. In Press. DOI: https://www.sciencedirect.com/science/article/pii/S0925963521004623?via%3Dihub