The pressing need for surfaces and fabrics that can be protected against microbes has been laid bare by the Covid-19 pandemic. Research published online in Advanced Materials has presented a method for coating fabrics with a liquid metal to kill any pathogens they come into contact with.

Study: A Liquid Metal Mediated Metallic Coating for Antimicrobial and Antiviral Fabrics. Image Credit: Kolomiiets Iryna/Shutterstock.com

The Importance of Antimicrobial Fabrics

Pathogens can survive for a long time on the fabrics commonly used for bedding, clothing, and face masks in healthcare and community settings. This is especially concerning in hospitals, where outbreaks of drug-resistant superbugs are becoming more widespread.

Additionally, it has been reported that the virus that causes COVID-19 can survive for up to two to three days on fabric. Pathogens can be transmitted from patient to patient after contact with the infected material.

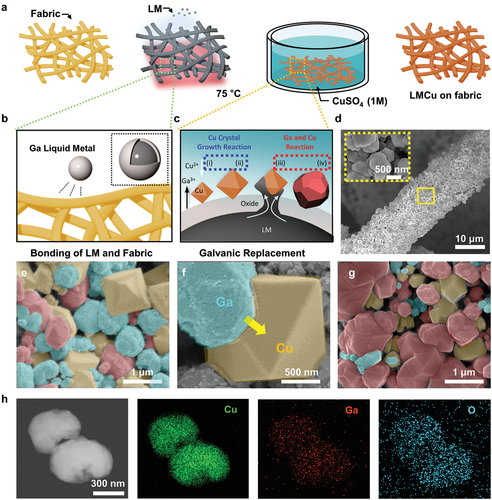

Liquid metal (LM) mediated particles coated on a fabric. a) Fabrication schematics of gallium-copper (LMCu) coatings on fabric. b) Schematics of adhesion of LM particles on the fabric by conformal contact. c) Schematics of galvanic replacement (i–iv) LM particles on fabric with Cu ions. d) SEM images showing LMCu on a single fiber (inset). e–g) Surface characteristics of LMCu coated on a fabric formed by reaction with 1 m CuSO4 solution. e) The surface of the Ga LM particles (cyan) serves as the seed to grow high crystalline (111) Cu (orange) after 10 min. f) The Ga particles (cyan) wet the surface of the adjacent copper crystal (orange). The arrow explains the wetting direction of Ga to make LMCu particles. g) As a result, LMCu particles (red) form on the surface after 1000 min. h) High-resolution transmission electron microscopy (HR-TEM) image and corresponding energy-dispersive X-ray spectroscopy (EDS) elemental maps of the produced LMCu particles, respectively. (Cu (green), Ga (red), and O (blue)). Image Credit: Kwon, K.Y et al., Advanced Materials

Fabric facemasks are deployed to stop the spread of airborne and droplet-spread pathogens by trapping microbes in the fabric. However, whilst the pathogens are trapped, stopping them from infecting the wearer, they are not killed. If proper handling procedures are not followed, the pathogenic microbes can still infect individuals. This is an incredibly common occurrence. Therefore, there is an urgent need for fabrics with antimicrobial coatings.

Current Antimicrobial Coating Strategies

Currently, there are several strategies to create antimicrobial coatings for fabrics. These include coating them with agents such as polymers, 2D materials, metal particles, and organic-metal frameworks. However, each of these strategies has drawbacks that affect the efficacy of their use as antimicrobial coatings.

For example, copper nanoparticle-coated or impregnated face masks have recently been approved for commercial use. Copper nanoparticles show a broad spectrum of efficacy against viruses, bacteria, and fungi. Additionally, copper is low-cost, presenting a cheap solution to the problem.

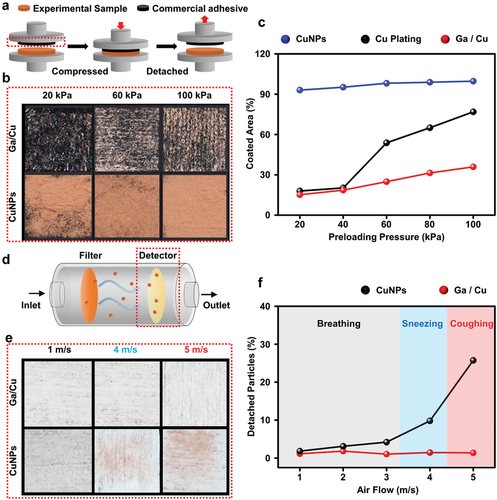

However, these coatings can easily fade over time and have issues with adhesion and nonuniform covering. Clearly, in the case of facemasks, this is a major drawback.

Enhanced adhesion of LMCu on fabric. a) Schematic of the peel-off test method. b) Peel-off test results comparing the LMCu coated fabric and spray-coated CuNPs which represent conventional methods of depositing copper on fabrics. A real image of the compression pressure measured from 20 to 100 at 40 kPa intervals. c) Measurement of the amount of Cu buried on the carbon tape compared to the total area quantitative analysis of the peeling test by pressure. d) A schematic of the detachment test through the transient airflow, which simulated respiration systems. e) The degree of particle desorption (top: LMCu, bottom: CuNPs) in response to airflows to represent breathing (1–3 m s−1), sneezing (4 m s−1), and coughing (5 m s−1). f) Quantitative analysis by image processing. Image Credit: Kwon, K.Y et al., Advanced Materials

Liquid Metal Mediated Antimicrobial Fabric Coatings

To overcome these issues, the team behind the research published in Advanced Materials developed a novel process to provide superior antimicrobial coatings for fabrics. The process uses liquid metal to mediate the deposition of copper nanoparticles onto materials at room temperature.

The process uses liquid gallium particles that act as an adhesion nucleation layer. In the process, copper ions are spontaneously reduced into metallic copper by galvanic replacement. The team termed the new class of particles “LMCu particles” and contain both copper and alloys of gallium and copper.

The first step of the process involved adding a liquid metal particle suspension to the fabric and then evaporating the solvent. Then, the coated nonwoven fabric was immersed in a 1M solution of CuSO4 and the LMCu particles were spontaneously formed. Copper crystals grew on the liquid metal oxides from initial seeds. Carbon, a major component of the material tested, was not detected in the final coating, strongly demonstrating that LMCu particles covered the entire surface of the fabric.

The fabric used in the study was a mixture of 45% polyester and 55% cellulose, although the coating worked well on a range of tested materials. Using scanning electron microscopy, it was found that 3 coatings fully covered the fabric. The particles exhibited enhanced levels of adhesion to the fabric, and this seems to be due to a combination of the “soft” nature of liquid particles and surface oxides that form on gallium.

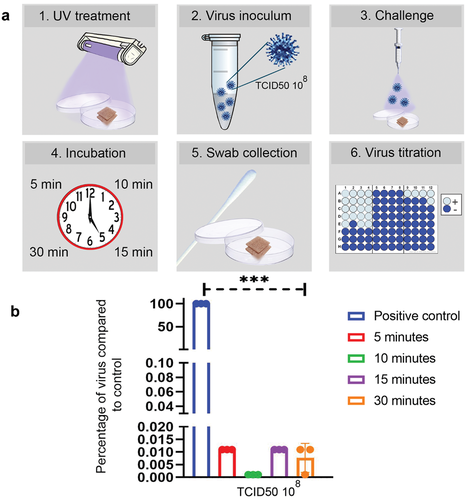

Furthermore, the LMCu particles have better antiviral, antifungal, and antibacterial properties than pure copper. The unique properties of this class of nanoparticles make them ideal for use as an antimicrobial coating that is far more durable than alternatives on the market currently.

LMCu Coated Facemasks

The study presented a facemask design that utilizes gallium and copper-coated materials. There is a danger with conventional copper-based antimicrobial coatings of copper particles becoming detached and entering the respiratory system of the wearer, which could cause health problems. However, the adhesive layer of LMCu particles prevents this, increasing the safety of the coated material whilst providing enhanced antimicrobial protection.

An antimicrobial-coated facemask must also cope with an obvious factor: the wearer breathing. Breath is moist and warm, leading to changes in humidity. The facemasks were evaluated over a range of humidity, displaying the same adhesion properties at both low and high humidity.

They were also evaluated for airflow, considering actions such as breathing, coughing, and sneezing, again displaying superior performance. Delamination tests were carried out by applying pressure and using carbon tape.

Antiviral testing of the LMCu coated fabric. a) Schematic experimental setup and b) Viral titers from LMCu coated fabric were analyzed after 5, 10, 15, and 30 min incubations post-challenge with human Influenza A H1N1 virus inoculum (108 TCID50). The inoculum of 108 TCID50 not exposed to the mask was used as the positive control. Samples were collected after each time point from the front and back of the LMCu coated fabric and sections were frozen and assessed using TCID50 method. Results were analyzed via ANOVA, showing statistically significant differences between positive control and all incubation time points (*** = p < 0.01). Image Credit: Kwon, K.Y et al., Advanced Materials

The Future

The study demonstrates a novel antimicrobial coating fabricated by a liquid metal-mediated process. Results of the research showed that this coating has superior adhesive and antipathogenic qualities, paving the way for safer fabrics that will help stop the spread of harmful diseases in the future.

Further Reading

Kwon, K.Y et al. (2021) A Liquid Metal Mediated Metallic Coating for Antimicrobial and Antiviral Fabrics [online] Advanced Materials 33:45 3104298 | onlinelibrary.wiley.com. Available at: https://onlinelibrary.wiley.com/doi/10.1002/adma.202104298

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.