Volcanic eruptions can have a catastrophic effect on human life and property but leave behind an abundant resource: volcanic ash. To explore how this natural material can be used in construction, a paper published in Ceramics International has demonstrated the use of volcanic ash as an additive in bricks.

Study: The use of Mount Etna volcanic ash in the production of bricks with good physical-mechanical performance: Converting a problematic waste product into a resource for the construction industry. Image Credit: Mikhail Cheremkin/Shutterstock.com

Investigating Volcanic Ash as a Construction Material

Whilst many organic and inorganic waste materials have been investigated for their use as additives for the manufacture of ceramic materials, there has been relatively little research on the use of volcanic ash.

The chemical and mineralogical content of volcanic ash is related to the content of the magma from which it originates. There has been some research into the use of volcanic ash as additives for mortars and concrete and archaeological evidence has shown its use as raw construction materials in Roman and Mayan sites.

![PXRD diagrams of the volcanic ash (a), the raw material (b) and oriented aggregates from the clay fraction (c, d and e). These aggregates are: air dried (c), heated at 550 ?C (d), and treated with ethylene-glycol (e). Legend: Pl = Ca-plagioclase; Aug = augite; Ol = olivine; Mag = Ti-magnetite; Qz = quartz; Cal = calcite; Dol = dolomite; Sme = smectite; Ilt = illite; Chl = chlorite; Kln = kaolinite; Pg = paragonite. Mineral abbreviations after Whitney and Evans [79].](https://www.azom.com/images/news/ImageForNews_57422_16376719131442581.jpg)

PXRD diagrams of the volcanic ash (a), the raw material (b) and oriented aggregates from the clay fraction (c, d and e). These aggregates are: air dried (c), heated at 550 ◦C (d), and treated with ethylene-glycol (e). Legend: Pl = Ca-plagioclase; Aug = augite; Ol = olivine; Mag = Ti-magnetite; Qz = quartz; Cal = calcite; Dol = dolomite; Sme = smectite; Ilt = illite; Chl = chlorite; Kln = kaolinite; Pg = paragonite. Image Credit: Cultrone, G. Ceramics International

Recent research into the use of volcanic ash includes replacing K-feldspar with milled volcanic ash for white-type ceramics. Volcanic ash has also been combined with waste glass to construct porous cement that can help with controlling humidity in building walls. Sieved volcanic ash was combined with clayey materials to manufacture ceramic tiles with similar mechanical and physical properties as commercially available products.

Using Volcanic Ash from Mount Etna

Volcanic ash is ejected from eruptions and settles on the surrounding towns, cities, villages, and countryside. When it settles, it can cause damage to buildings and property and loss of life. Mount Etna in Italy is one of the world’s most active volcanoes, with an activity that can last anywhere from a few hours to six months.

Typically, Etna’s activity lasts a matter of weeks. Aside from its impact on the surrounding area, Etna’s cultural significance can be seen in monuments from the Roman to Baroque eras mined from Etna’s basalt.

Ash outcrops are not exclusive to Etna as they can be found in many areas of the world. Factors that influence the spread of volcanic are the eruption’s duration, the plume’s height, and the prevailing winds.

Ash that settles on buildings, infrastructure, roads, and airports is cleaned up after each eruption, creating a problem with waste and disposal as the area around Mount Etna can become covered with several kilograms per square meter of land during an eruption.

![a) grain-size distribution curves for the clayey material (VG) and the volcanic ash (va); b) general view of ash particles under FESEM; c) detailed image of a fragment in which Ca-plagioclase (Pl) and Ti-magnetite crystals (Mag) have been identified (see EDS spectra). Mineral abbreviations after Whitney and Evans [79].](https://www.azom.com/images/news/ImageForNews_57422_16376719227357227.jpg)

a) grain-size distribution curves for the clayey material (VG) and the volcanic ash (va); b) general view of ash particles under FESEM; c) detailed image of a fragment in which Ca-plagioclase (Pl) and Ti-magnetite crystals (Mag) have been identified (see EDS spectra). Mineral abbreviations after Whitney and Evans. Image Credit: Cultrone, G. Ceramics International

Making Bricks from Mount Etna Volcanic Ash

The paper published in Ceramics International explored the use of this material as an additive for bricks that could be used widely in the construction industry, improving the mechanical and physical properties of this construction element whilst also overcoming the problem with the disposal of waste ash.

Additionally, using this abundant natural resource would reduce the need for fossil fuels and finite, non-renewable resources. This use of the material is in line with the European Commission's Green Deal.

The study used raw brick materials from a factory in Spain which comprised two clayey soils from Viznar and Guadix in a 4/5, 1/5 ratio. These clayey soils originate in the Grenada and Guadix-Baza basins. The volcanic ash was recovered during a prolonged eruption from the new southeast crater of Mt. Etna. It was collected at the end of August 2020 in the province of Catania.

The raw clayey material was milled and sieved, and 10$% and 20% volcanic ash was added by weight. A factor that allows for easy comparison with other waste materials is that volcanic ash has virtually the same weight and volume percent. In order to ensure the consistency of the bricks, higher concentrations of volcanic ash were disregarded. The raw material and ash were mixed by hand, with water added to create a homogeneous mixture.

4cm cubes were produced after compacting and setting in a mold. These were then smoothened and fired in an oven at high temperatures. The entire process took 24 hours. Nine types of brick were produced, with different combinations of firing temperature (800, 900, and 1100oC) and raw material/volcanic ash concentration.

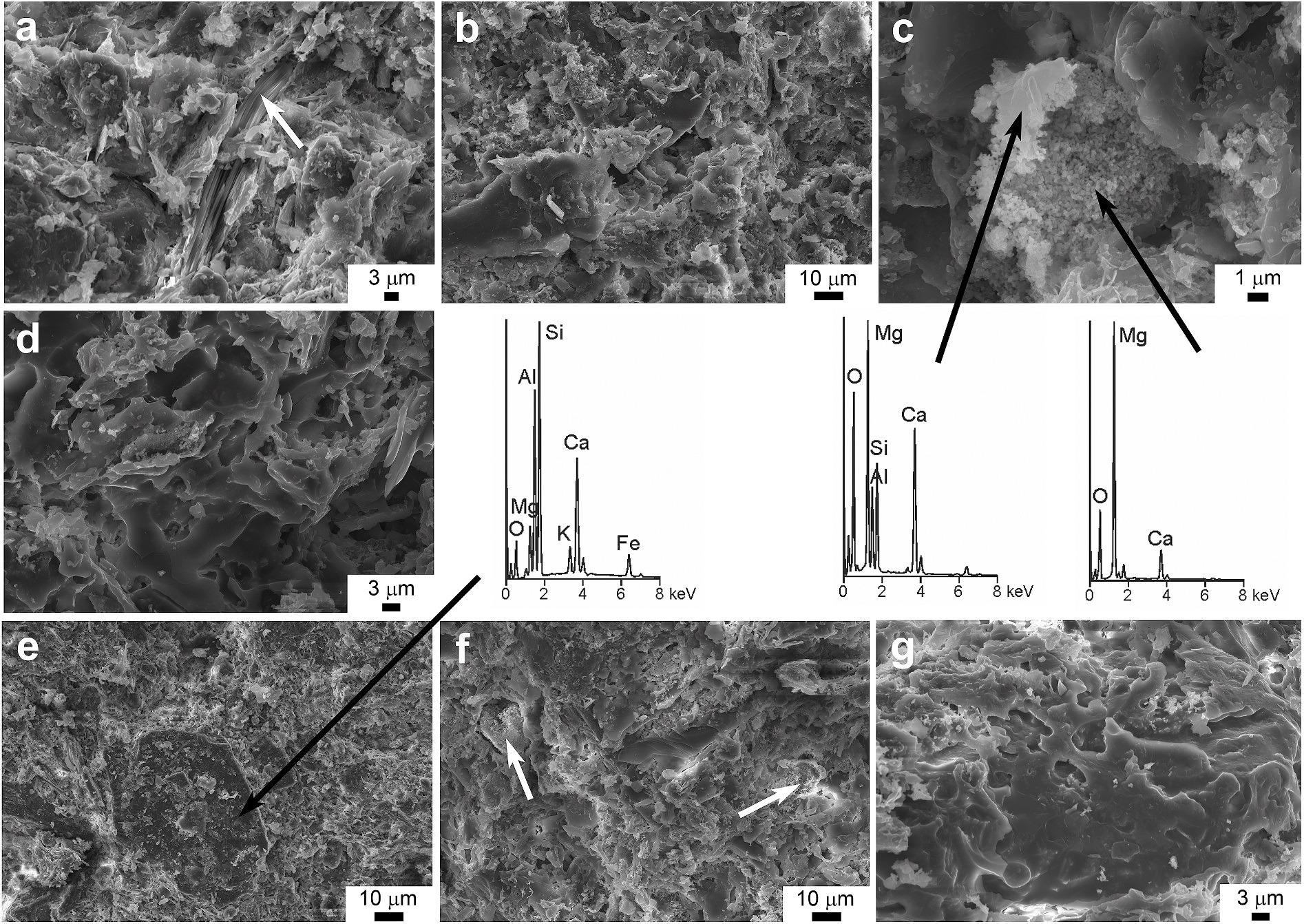

FESEM secondary electron images and EDS spectra of the bricks made without additive (image a belongs to VG800, b and c to VG950, d to VG1100) and of those containing 20 wt% volcanic ash (image e belongs to VGb800, f to VGb950, g to VGb1100). Image Credit: Cultrone, G. Ceramics International

It was discovered that adding 10-20% of volcanic ash made the bricks less porous. Due to vitrification and sintering processes, the compactness of the bricks was improved as temperature increased (as well as retaining their orange color.) The bricks showed less strength when volcanic ash was added, but this was still within acceptable parameters, and they were less susceptible to decay. Generally, firing at higher temperatures improved the behavior of the volcanic ash enriched bricks.

The Future

The results of the study demonstrate that volcanic ash can be used to improve the mechanical and physical properties of bricks. An abundant and renewable resource, using this natural material could help the construction industry meets its green targets whilst solving the issue of waste disposal.

Further Reading

Cultrone, G (2021) The use of Mount Etna volcanic ash in the production of bricks with good physical-mechanical performance: Converting a problematic waste product into a resource for the construction industry [online] Ceramics International | sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/pii/S0272884221035380

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.